Choosing the right wood oil for a project can be a complicated task; you risk ruining the wood surface or creating an unsatisfactory finish by using the wrong product. But you’re in good hands!

In this post we look at how you can improve the look and the protection of your wood surfaces – internal and exterior – by using wood oils, and the advantages of using advanced wood oil products over their traditional counterparts.

Why You Can Trust Rawlins 👍

At Rawlins, we pride ourselves on our extensive expertise in providing high-quality coatings and finishes for various surfaces. With decades of experience in the industry, our knowledge and product offerings are trusted by professionals and DIY enthusiasts alike. Whether you’re looking for durability, aesthetic appeal, or both, you can rely on Rawlins for expert advice and exceptional products tailored to meet your needs, such as these wood oils and more. Our selection of all-year-round masonry paints ensures your projects are protected in any season, while our range of over 4,400 colours for uPVC windows and doors gives you endless possibilities for customisation.

We’re rated 4.8 stars out of 5 on Trustpilot for a reason – and we’re always busy working on the other 0.2.

What is Wood Oil?

Wood oil is a protective and decorative wood finish that can be applied directly to bare wood and timber. Wood oils provide a deep penetrating, long term, and cost-effective finish for wooden surfaces and nourish the wood from within, replenishing woods that may have dried out from exposure or uncared for.

At Rawlins Paints we stock traditional wood oils (Danish, Teak, Linseed) and newer, advanced, next-generation wood products that are much more user-friendly and combine the advantages of oils, waxes, and varnishes in one tin. More on these further below.

As opposed to high VOC wood varnishes, wood oils are predominantly natural products which are easy to apply, as well as maintain over long periods of time. Osmo’s advanced wood finishes are based upon purified and refined natural resources, using carefully harvested natural oils (sunflower, soya, linseed and thistle oils) and hard waxes (carnauba and candelilla waxes) for its finishes. The dry finish is safe for humans, animals, and plants, and therefore suitable for children’s toys, being resistant to perspiration and saliva.

Wood oils can, in some instances and with the correct preparation, also be applied over the top of wood stains. This usually requires light abrading with a fine sand paper – always research and test beforehand, our technical team are on hand to advise the best products and application for your project.

Why Does Wood Need Oiling?

For protection and decoration. Wood oil penetrates the wood, seeping in to replace and replenish natural oils which may be lost through exposure, age, and general wear and tear. It can also revive a wooden surfaces’ natural colour, bringing it ‘back to life’. Existing wooden surfaces, be it furniture, timber, etc, can be completely transformed by using wood oils.

Exterior wooden surfaces are affected by environmental factors and damage from attack and exposure, such as:

- Moisture and waterlogging, caused by open exposure of the surface to the elements.

- UV light radiation makes lignin water-soluble in wood, which is washed away by rain, leaving wood to become brittle and grey.

- Blue stain, fungal, and algae attack exterior wood, destroying its substance and creating dark spots.

- Insects such as wasps feed off of wood, causing damage to surfaces and supports.

Pooling water and accumulation of dirt and grime on exposed horizontal surfaces such as decking, and garden furniture, will significantly reduce the UV resistance of treatments if they are left uncleaned and not maintained for lengthy periods.

Untreated wood surfaces that are exposed to sunlight will begin to fade and grey over time. This isn’t a necessarily bad thing if you like the look of weathered wood. For those that prefer the natural hue and highlights, you’ll need to apply UV-resistant wood oils, such as those from Osmo.

What are the Different Types of Wood Oil?

Tung oil vs Linseed oil vs Danish oil

If you have previously used a specific traditional wood oil on the wood you are treating, it is best to continue using that oil. New projects or bare and untreated wood can use one of several oils, with each giving a different finish and level of lustre.

There are specific oils recommended for certain woods, which we look at in more detail below, as well as our advanced wood oils from Osmo. These next-generation products are much more user-friendly than our traditional wood oils and have wider compatibility with different species.

Danish Oil

More of a thin oil and varnish mixture than other wood oils, Danish oil can protect wood against chemical damage, exposure to heat, superficial scratches and stains.

Taking approximately 15 minutes to soak into the wood, Danish oil should only be applied one layer per day. Additional layers will build up a thick, durable coating like wood varnish.

Noticeable for having a faster drying time than linseed oil, Danish oil works best on new and untreated wood surfaces, giving a lustrous finish.

Hard Wax Oil

Considered as a compromise between traditional oils and a tougher protective coating against liquid spillages, hard wax oil can be used on hardwood floors and kitchen worktops.

Hard wax oil can be mixed with coloured oils and applied by brush or roller, without leaving ‘swirl’ marks. It noticeably enhances the wood’s natural colour and grain, allowing it to naturally age with rich and varying tones.

Linseed Oil

Rawlins Paints has published an in-depth article about boiled linseed oil.

Raw linseed oil is most famously used on cricket bats, taking a long time to soak in and dry out. Previously oiled cricket bats will only need one new coating of linseed oil when re-applied, after having the surface slightly sanded back. During the cricket season it is common for bats to be re-oiled once a month.

After the linseed oil has soaked into a surface, wipe away the excess oil and then buff the surface with a clean cloth. To reach a desired finish, several layers of linseed oil may need to be applied, with sufficient drying time between each coat.

It is not recommended to use linseed oil on exterior and exposed woods.

Mineral Oil

Mineral oil is a low sheen, non-drying oil that is used by woodworkers. Food safe wood oils are available for use on kitchen cutting boards, and whilst they are non-drying, they can be washed off.

Considered more of a wood treatment than a wood finish, due to it being non-drying, mineral oils will not leave a dried and solid film on wood.

Light mineral oil can be used on wood crockery, such as ornate bowls.

Olive Oil

Olive oil is another non-drying wood oil that is vegetable based – similar to peanut oil. Non-drying oils like vegetable oil or olive oil, should never be used on food storage bowls, as they will leave a sticky and smelly finish that will spoil stored food.

Olive oil used to be the traditional and ancient method of protecting worktops and treating wood surfaces, but it was found to have several drawbacks; the surface would always remain wet, did not protect against moisture for long, and helps bacterial growth. Hardly the best oil for use around food!

Teak Oil

Suitable for exterior and interior wood surfaces, teak oil beautifies the wood grain, protecting it against UV rays and water stains.

When applied to wood, the excess oil should be removed before the teak oil has dried, with additional coats added every 24 hours. It is recommended to maintain teak oil protected surfaces with a fresh layer 1 to 2 times a year. After the finishing layers have been applied and lightly sanded, teak oil can be buffered up to leave a silky-smooth surface.

Yacht and boat decking are commonly protected by teak oil.

Tung Oil

Tung oil is also known as China wood oil, and as with most other oils dries with exposure to air. It’s a plastic like, clear coating that is used away from wood finishing in printing inks and oil paints.

When used on guitars, tung oil leaves a wet wood look, that has a slightly golden tint.

Often considered to be the finest and most natural finish for wood, it does require a different application process.

Rust-Oleum’s shabby-chic chalky-finish paints are ideal for wooden surfaces

Rust-Oleum’s shabby-chic chalky-finish paints are ideal for wooden surfaces

Next-Generation Wood Oils

As you can see above, traditional wood oils can take a lot of time to apply and lots of preparation before and during application to ensure a brilliant and protective finish. Whilst this may suit woodworkers, others such as consumers and professional applicators are demanding wood finishes that are easier to apply, quicker to dry, and provide excellent protection for wood surfaces.

Advanced, next-generation wood oils from Osmo provide these much-wanted features and the advantages of wood oils, varnishes, and waxes, over their traditional counterparts:

- User-friendly application

- Fast drying

- Hardwearing protection in just one or two coats

- Long-lasting, durable finishes

- Very easy to maintain

- Require much less preparation to apply more coats later

- Beautiful finish comparable to that of traditional wood oils

- Large choice of colours

- Anti-greying and excellent resistance to UV light, dirt, etc

- Wide range of compatible wood species

What Wood Oils Should I Use For…

Interior Wood Surfaces

Interior Wood Floors

One of the main preferences of wood oil for flooring is that it brings out the characteristics of the wood grain, adding a unique finish to a floor. They are designed to add waterproofing protection, against spills and seasonal elements.

Wood floor oils can be used on solid softwoods and hardwoods, as well as engineered wooden flooring. Rawlins Paints stock a wide range of wood protection products for use on most type of wood flooring including veneers, MDF, plank, strip, OSB and cork flooring.

Designed to withstand abrasion from heavy pedestrian traffic, wood floor oils come in a range of different finishes to add a durable coating that will last for years. These are ideal for commercial usage in shops, offices, public services, cafes, and restaurants, making a wood floor the centrepiece.

Wood floor being treated with Osmo Polyx-Oil

Osmo wood oils are formulated safe for use on areas frequented by children. They are suitable for use on wood floors at home where they like to play, at school or nursery, and on children’s wooden toys and activities. Osmo Polyx-Oil Rapid is suitable for all wooden floors such as solid wood, plank, strip, OSB and cork flooring.

Interior Wooden Furniture

Traditional wood oils help prevent surfaces on cupboards and wardrobes, chairs and beds, side tables and décor from drying out. Because wood oil sits in, rather than on the wood surface, it means your wood furniture can still be scratched and damaged from abrasion. Stacking clothes onto chairs, standing on a side table to do some DIY, or writing at a table, for example.

Our advanced, next-generation wood oils for furniture will bind to the wood, enriching with natural oils and protecting your expensive and beloved wooden furniture with a durable finish that lasts far longer than traditional products.

With such low maintenance needed, our advanced furniture wood oils are ideal for not just the home, but workplaces with featured wooden surfaces and furniture, including stately homes, offices, and libraries.

Interior Wood Doors and Trim

Interior doors must put up with a lot of abuse – being slammed in arguments, knocks and scuffs and scratches, handprints, and finger marks from dirty or greasy hands – even slobbered on by dogs!

If you close your internal doors during winter to keep rooms warm, one side of the door will be expanding in the heat whilst the other contracts in the cold hallway on the other side, multiple times a day. That is a lot of movement and attack on the timber.

Our advanced wood oils are ideal for the protection of joinery, solid and some selected veneered wood interior doors (please consult door manufacturers’ recommendations), protecting the surface against abrasion and dirt and being easier to keep clean.

Osmo Door-Oil uniquely combines the advantages of natural oils and waxes in one product. Designed for all internal solid wooden doors and joinery, and some selected veneers, its application process is simple. There is no primer or sanding required between coats, resulting in a microporous surface will not crack, peel, flake or blister.

Walls and Ceilings

Wood panelling, beams, and mantles will have to withstand many elements as you work inside. In kitchens with wooden beams, for example, there may be a build-up of grease and fat, as well as smoke deposits. Ceilings that are panelled will absorb moisture in the air but can also dry out in heated rooms, as heat rises.

Wood Worktops and Tabletops

Keep your worktops, tables, counters, butcher’s blocks, and kitchen islands looking their best, bringing out the natural beauty of wood whilst protecting against spillages from food and drink, juices, and oils from preparing meat, vegetables, and fruit.

The new and advanced Osmo TopOil is food safe (EN 1186) and ensures your worktops are protected with a durable and hardwearing finish that can easily be cleaned and kept hygienic. Osmo TopOil is extremely resistant to water and chemicals, including common liquid spillages such as water, juice, tea, cola, and wine. It can be used on a wide range of wood types including oak, pine, and beech.

Exterior Wood Surfaces

Exterior Joinery (Windows and Doors)

Wood windows and doors can really add to the character of a house, whether it is a vintage cottage or a recently converted barn or farmhouse. Given that these woods are exposed to the elements, they need routine care and maintenance to ensure that the wood does not dry out, and that any damage is quickly repaired.

Whilst they can be treated with traditional oils like Teak, Danish, and Linseed, these do not provide prolonged UV resistance unlike our next-generation wood oils for exterior windows and doors:

Osmo UV-Protection Oil is ideal for all vertical wood surfaces in outdoor areas and is available in 2 varieties; 410 is safe for humans, plants and animals when dry and is available in a tinted version also; Clear UV Protection Oil 420 Extra is furnished with active ingredients to protect against mould, algae and fungal attack.

Using Osmo UV-Protection-Oil helps to slow the greying process of exterior woods by (UV factor) 12 times in comparison to untreated wood, and requires much less maintenance than traditional wood oils used on exterior joinery. It has a wide range of suitable wood types including oak, thermowood, pine, spruce, cedar, mahogany, teak, and much more. See the website listing page for the full list as well as specifications for base coats and weathering periods for ingredient-rich wood species.

Wooden Garden Furniture

Furniture oils are more generally used on exterior wood furniture, such as benches, tables, and chairs in hospitality industries – think cafes, restaurants, gastro pubs. Garden furniture oil can be used on softwood and hardwoods, giving a high quality and low odour finish.

Traditional wood oils, such as teak oil, are popular choices for protecting outdoor wood furniture. It protects, maintains, and improves the appearance of garden furniture made of Teak and other hardwoods in covered outdoor areas. It penetrates deep into wood surface, regulating moisture, prevents swelling and shrinkage, and is highly water and dirt resistant.

Wood Cladding

Timber cladding is rising in popularity not just for its natural looks, but also how easy it is to maintain – if looked after correctly. You will see timber cladding on all sorts of buildings, not just barns and garden offices but cafes, offices, restaurants, and pubs, particularly those in woodland areas and parks.

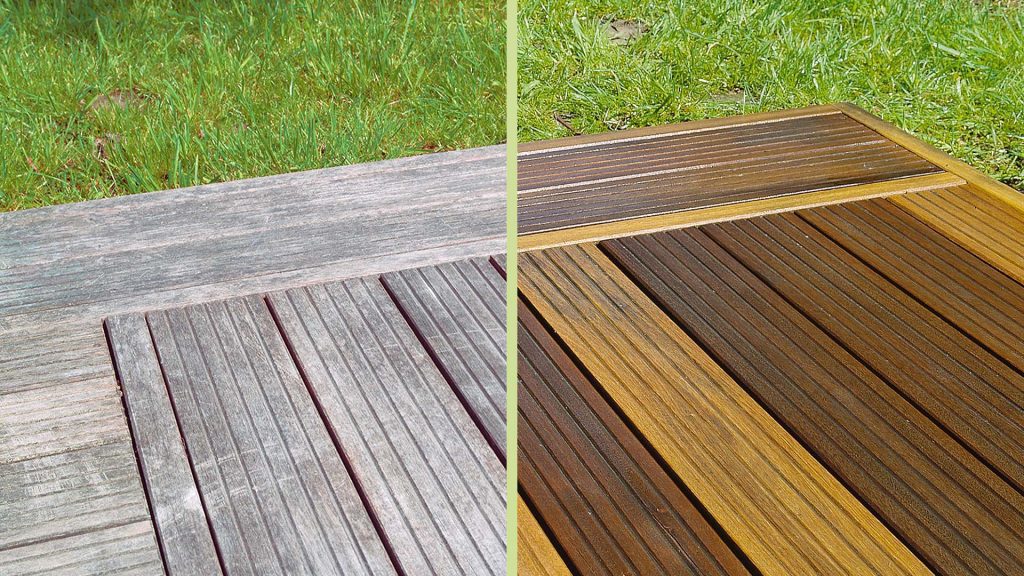

Before and after using Osmo UV-Protection-Oil

Wood cladding that is not suitably protected can dry out in hot sun over summer, warping, splitting, and cracking. Our wood oils help ensure that cladding can breathe and is saturated, penetrated, and stabilised, to minimise damage and maximise weather resistance, no matter the season.

Before applying wood oil to cladding, be sure to check that the wood cladding doesn’t require fire protection. Exterior wood cladding on buildings will often need fire protection to prevent the spread of flames, and if the surface is oiled then it is much harder – near impossible – to upgrade to fire certification successfully.

Whilst traditional linseed oils can be used to refresh and protect wooden cladding, ultra-modern alternatives exist that are far more user-friendly with quicker application and longer-lasting conservation for wood surfaces.

Osmo UV-Protection Oil is a next-generation wood oil that is biocide-free and designed for use on vertical outdoor wood surfaces – such as cladding. It slows the greying process by up to 12 times and requires no sanding when topping up the coating, making it very user friendly and economical to work with. It can be used with popular wood types including oak, beech, ash, alder, birch, and thermowood, with many others by using a base coat or after a 12-week weathering period.

Wood Decking

If you’re looking for long term protection of newly laid decking, picking the best decking oil used to be tricky. Luckily, at Rawlins Paints, we have next-generation decking oils that are much easier to apply and maintain that traditional oils and conventional products.

Before and after using Osmo Wood Reviver Power Gel

Decking oil can enrich and enhance colouring obtained from a decking stain, offering a durable coating that is weather resistant – waterproofing and offering UV exposure protection against greying, bleached out colour and a dull, weathered look come next summer. Most people prefer to keep the natural look of wooden decking, which is where clear decking oil would benefit this job best.

A common problem with decking is when edges and grooves start to split and crack. A high-quality decking oil can prevent this from happening, making the surface a lot more durable against medium to heavy pedestrian traffic.

Your decking deserves a long-lasting and tough wood oil that can protect it against algae and fungal damage, and these are amongst the best products that do this:

Osmo Decking-Oil meets the demands of wooden decking with a variety of colours and unsurpassed durability for all weather conditions. It is extremely weatherproof and UV stable with a microporous, penetrating finish which does not crack, peel, or flake. Breathable, it reduces water logging, swelling, and shrinkage, is suitable for suitable for treating popular and exotic wood types including oak, pine, spruce, and thermally treated wood. Osmo Decking Oil also has an anti-slip version available.

Wooden Sheds, Fences, and Summerhouses

Wood oils help protect the integrity of wooden sheds, fences, and other outbuildings by repelling water and resisting the harmful effects of UV lights, helping prevent wood from splitting or warping.

Sheds are designed to lock tools away whilst fences divide properties or sections of the garden. An inviting hole from damage can lead to infestations of pests; mice will chew your parasol fabric for nesting, and rabbits breach your fencing and help themselves to the vegetable patch.

Not to mention, fencing and sheds are not cheap to replace! Whilst traditional wood oils may be cheaper to buy, our advanced wood oils provide excellent protection and are much more user-friendly to apply and keep maintained, with no sanding required when topping up. Use our recommended wood oils to keep your wooden garden structures in tip-top condition, not just to guard against unwanted pests, but renewing the look of the wood and enhancing its natural beauty.

Osmo UV-Protection Oil is another of our modern wood oils with several advantages over traditional products. Furnished with active ingredients to protect the coating against mould, algae and fungal attack, it is safe for humans, plants and animals when dry and works by slowing the greying process by (UV factor) 12 times in comparison to untreated wood. Osmo UV-Protection Oil can be applied without sanding and requires just 2 coats to leave your exposed wood surfaces with a water-repellent finish that will not crack, peel, or flake. It can be used on oak, beech and Thermowood, with more species compatible with using a base coat or after a 12-week weathering period.

How to Apply Wood Oil

As stated further above, our next-generation advanced wood oil products are much more user-friendly and easier to apply and maintain than traditional wood oils. All of our wood oils have their respective product data sheets available to download from the “Data Sheets” tab on the website, which include preparation and application instructions.

Wood oils can typically be applied over stained wood, with the correct preparation. Osmo recommends abrading the surface with fine sandpaper beforehand – always test your application methods before committing to the project, or give our technical team a call on x.

Wood oil is best applied to off-cuts of wood first, if available – such as spare decking board or scrap wood that is the same as the surface being oiled. If a wood oil is being used on different woods within an items construction, or within the same room, remember that one oil will give different finishes (visually) to different woods. Due to this, you may need to tint oil used on lighter wood to match darker wood – cedar, for example, is darker than pine.

Wood oil should only be applied to wood that has not been sealed. Externally wood that has been finished with an oil may lose its finish due to exposure to the elements but will stay protected. Interior wood surfaces are much more likely to retain the oiled finish.

How To Look After Finished Wood Surfaces

At Rawlins Paints we also stock maintenance and repair products for your wood surfaces, internal and external, to help maintain your wood oil finishes for longer.

Interior Maintenance

Cleaning and maintaining your interior wood surfaces regularly will help cut down on expensive or time-consuming repairs to your cherished furniture and revered fittings.

Wood Floors

The key to wood floor protection is to prevent damage from occurring in the first place. Using mats, at the entrances of doors, will reduce the amount of dirt and gravel from being trodden into your wood floor. Self-adhesive floor protector discs can also be affixed to the underside of table legs and chairs. These prevent furniture from scratching your wood floor when moved into position or shunted around during a raucous dinner party.

Mopping up spillages as they happen will stop residues from marking wood, requiring a more in-depth clean to restore the surface. Preventing spiked shoes and stilettos from marking the floor will save on filler to repair holes and scuffs.

Be sure not to use all-purpose cleaning products or power-type abrasive cleaners as they could contain bleach, chlorine, ammonia. They will damage the wood oil and possibly strip the wood of protection. Spray polishes and furniture wax will make the floor slippery and dangerous to walk on. Steam cleaning can cause moisture to seep in between the boards of the wood floor and make it warp.

Cleaning your wood floors regularly with interior wood cleaners will help reduce major work needed to maintain them, reducing downtime and disruption for businesses, and allowing homeowners to enjoy their floors.

Repairing Scratches

Osmo recommend simply applying a small amount of their oil onto damaged areas, rubbing with a cloth, and then removing the excess. This can be done as oils can be applied layer upon layer; a bonus over varnishes, which must be sanded back to the bare wood before reapplying.

Larger scratches will require sanding; Osmo recommends 80 grit on the bulk of the scratch, finishing with 120 grit before reapplying their wood oil.

Removing Water Marks

Water will tightly bead on wood surfaces treated with high water resistance, such as Osmo Polyx Oils and TopOil, without leaving permanent marks. If left for many hours, however, then any marks would need to be lightly sanded before being re-finished.

Water damage often occurs on wooden worktops – counters, tables, butcher blocks, breakfast bars, kitchen islands – as they are regularly used near water and heat. and therefore more vulnerable. Use coasters and placemats when dining as well as trivets when placing hot pans direct from the stove, to rest or to serve from. These preventative measures will reduce wear on the surface but, as anyone who cooks will know, splashes and spillages from hot oils, wine, coffee, tea, and juices are unavoidable.

Always clean up spills to help minimise damage, using surface cleaners that are specifically developed for oiled wood. This stops wood from drying out, maintaining its sheen, and avoiding new applications of protective oils. Avoid using traditional cleaning products as their chemicals can stain, discolour, and bleach real wood.

Once your wood worktops no longer bead liquid on the surface, it can be a sign of the need to re-oil.

Exterior Maintenance

Seasonal weather such as heavy rain and pooling, frost and snow, high winds, and blisteringly hot sunshine will test even the most durable of wood oils. Build ups of dirt and debris will affect the UV protection abilities of wood oils. It is recommended to keep your exterior wood surfaces clean and clear of contaminants, fungi, and grease, to help prolong the life of the oils and the wood itself.

All exterior woods exposed to the elements will experience “greying”, a patina that builds up over time. Surfaces such as decking, cladding, and garden furniture can be renovated easily. Use revival products such as Osmo Wood Reviver Power Gel to restore the warm tones and natural characteristics of unweathered wood.

General outdoor cleaners are often found to be left wanting when cleaning decking of heavy soiling, dirt, and grime, even with a power washer. At Rawlins Paints, our specialist decking cleaners are effective for clearing exterior decking surfaces of contaminants easily with a brush or scrubber. This will help preserve coatings with UV protection for longer, or prepare the surface for an application of oil.

Peeling, Blistering, Flaking, and Cracking

Wood will expand and contract as it releases and absorbs moisture, therefore it must be allowed to breathe. Varnishes and lacquers, which sit on the surface, form a film that can flake and crack when under much stress. This must be sanded off and the wood finished with a suitable wood oil that penetrates, or bonds with the surface such as Osmo wood oils.

Blackening

Woods with a high natural tannic content, such as oak, will turn black when exposed to moisture that contains trace amounts of iron. Regular cleaning with fungicidal washes will help maintain the decorative appearance of oak and other woods.

How quick the blackening occurs depends on the levels of rain, wind, and sun that the wood is exposed to.

Frequently Asked Questions

Rawlins Paints receive a lot of enquiries about wood oils, and which are the best finishes for specific interior and exterior woods. It is a complicated area, due to the wide variety available and many people assume the better-known oils can be used on every type of job. They cannot, and if they are applied, they could ruin the wood or create a finish that is completely unsatisfactory. We have grouped together the most popular queries below, click on one to jump down:

- How Does Wood Oil Differ from Wood Varnish?

- Which Wood Oil Is Best for Specific Wood Types?

- What Wood Finishes Can Be Used Over Wood Oil?

- What Should I Do Before Applying Finishes?

- Why is my wood surface still sticky after applying wood oil?

How Does Wood Oil Differ from Wood Varnish?

Depending on your project and your personal requirements, wood oils and varnishes may suit you better than the other.

Wood oils nourish the wood from within, replenishing woods that may have dried out from exposure or uncared for. They provide a deep penetrating, long term, and cost-effective finish for wooden surfaces, protecting against spillages even after surface damage. Traditional products require some preparation before topping up or refreshing surfaces, whilst our next-generation wood oils from Osmo are far easier to maintain and reapply.

Varnish, on the other hand, sits on top of the wood with a hard protective layer that resists abrasion and liquids, but does not nourishing the wood. To renovate at a later date, existing varnish must be removed by sanding, a time-consuming process.

Varnishes are great if the wood has already been stained as it will help to protect the colour from scratches and damage, preserving it for longer. They are also useful for applying high-gloss finishes to wood. Fire-retardant varnishes, clear or coloured protective coatings, protect and beautify the natural appearance of wood surfaces and can offer BS Class 1, Class 0, EN Class B and 30 or 60-minute protection, depending on the requirement, circumstance, and system choice.

You cannot, however, varnish wood surfaces that have been coated with oils or waxes – these must be sanded back before application of wood varnish.

Which Wood Oil Is Best for Specific Wood Types?

When it comes to picking the correct wood oil for a job, it can depend on several factors, not least the type of wood it is. Picking a specific wood finishing oil could depend on how the wood has previously been treated, whether it is for interior or exterior use and if it will need to be light, medium, or heavily durable. Matching a piece of wood’s finish to surrounding décor is also something to take into consideration – if a room has lots of light wood finishes, you may not want a darkening wood oil finish.

One big factor of traditional wood oil finishes is their drying time – and it is not always best to pick the fastest drying wood oil. There is often a bigger reason for picking a slower drying traditional oil for specific woods – be it furniture, sporting equipment (cricket bats for example are historically treated with ‘slow drying’ raw linseed oil) or decking – such as the wood’s density, condition (ensuring it doesn’t have woodworm damage, which if it does, we have some excellent woodworm treatments) and age. These can affect how a traditional oil takes to it and the finished shade.

There are several forums online which discuss suitable and recommended traditional and advanced oil finishes for specific woods, and it is recommended doing further research for any specialist furniture or wooden construction away from those discussed in this post – guitars, speaker cabinets, etc.

Rawlins Paints have recommended wood oils – both traditional and next-generation products – for the most popular wood species below:

Acacia

This highly-figured wood often has its colour variations highlighted by wood oils when applied to the grain, from a golden brown to a deeper red. It has a similar care process to that of mahogany – click to jump down and see our recommended products.

Ash

Osmo Polyx Oils, Stain, and Door Oils are suitable for use on Ash, with clear and coloured options that enhance the look of the wood and provide a hardwearing, water-resistant finish.

Some users bleach the wood prior to oiling it, as oil can slightly darken the wood. If you are considering bleaching the wood, please contact us.

To help keep the natural blonde colour of ash, traditionally Danish and teak oil are some of the more popular oil finishes although they can slightly yellow or become richer in dark tones when the wood is exposed to excessive UV light.

Bamboo

Bamboo furniture and décor is typically finished with several light coats of teak oil.

Beech

Osmo TopOil is a food-safe oil-wax combination for protecting beech kitchen worktops, desks, and shelving, against water and chemicals. Use our range of Osmo Oils for protection of beech floors and stairs from spills.

Historically, beech wood worktops were finished with Danish oil as it enhanced the natural colour. It’s often been said that, when restoring old kitchen units and counters, “think about applying a fresh layer of Danish oil to truly bring the wood ‘back from the dead’”.

Cedar

Osmo UV-Protection Oil is recommended for cedar after an initial 12-week weathering period (to improve absorbency) and is ideal for all vertical wood surfaces in outdoor areas. For horizontal surfaces, Osmo Decking-Oils can be used – again, only after the weathering period.

Linseed oil was traditionally the recommended wood oil finish by woodworkers, cedar cladding users and craft enthusiasts.

Mahogany

As with cedar above, after a 12-week weathering period, exterior mahogany can be oiled with Osmo UV-Protection Oil (vertical wood surfaces) or Osmo Decking-Oils (horizontal wood surfaces) for extra protection for mahogany timber surfaces against damage from weather and UV light.

For interior use, mahogany has been historically treated with tung oil, linseed oil and teak oil. These three are great penetrating oils and whilst they will not leave a glassy sheen on the mahogany, they can be buffed up to produce a more brilliant finish.

Maple

A very thin application of Osmo Polyx Oils can be used on maple, after a trial, for protection from water spills and foot traffic.

Traditional wood oils such as tung oil or linseed oil can be used to finish maple and to bring out the curly, or tiger grain of the wood.

Oak

For decoration and durable protection of interior and exterior oak surfaces, our Osmo wood oil products can all be used on oak – as always, check the relevant data sheets before buying or applying.

Traditionally, tung oil has been used on oak to maintain its colour, however, if you wish to darken the oak then hard wax oil is preferable. Danish oil is popular, historically, as a finish on oak as it brings out its rich tones, as well as preventing staining to the surface.

Pine

For interior pine protection, Osmo Polyx Oils are simple to apply without the need or a primer or intermediate sanding, whilst Osmo TopOil is ideal for pine surfaces that require a food-safe finish. For exterior pine protection from weather and UV, Osmo UV-Protection Oil (vertical wood surfaces) or Osmo Decking-Oils (horizontal wood surfaces) are a great choice.

For pine dining tables, traditional raw linseed oil used to be the best choice as it will not contaminate food substances. Slightly more difficult to apply than raw linseed oil is tung oil, which is also water resistant.

Danish oil used to offer the most durable finish for pine furniture, although walnut oil could be used to bring out a slightly different finish in the wood.

Rosewood

Exterior rosewood surfaces can be weather and UV-protected, after a 12 week weathering period, by Osmo UV-Protection Oil (on vertical wood surfaces), or Osmo Decking-Oils (for horizontal wood surfaces) after 4-6 weeks exposure.

Traditional wood oils like raw linseed oil or teak oil can bring out the strong colour of rosewood furniture.

Teak

For other outdoor teak surfaces, Osmo UV-Protection Oil (on vertical wood surfaces), or Osmo Decking-Oils (for horizontal wood surfaces) provide excellent protection.

For indoor use, traditional specialised teak oil can be applied to teak wood – note that teak oil is not made out of teak. Historically, linseed oil or tung oil was preferred by woodworking professionals.

Walnut

Osmo Wood Wax Extra Thin is compatible with almost all woods, including walnut, and is favoured over traditional oils like Tung Oil due to its ease of use, shorter drying times, and one-coat application.

Willow

As well as the more popular woods above, Rawlins Paints have wood oil products for less common, rarer, and more exotic species:

- Spruce

- Alder

- Douglas Fir

- Birch

- Larch

Osmo Polyx-Oil Original is compatible with these wood species used in interior flooring and furniture. Use Osmo TopOil for worktops, desks, and shelving in these species.

Oily and resinous, ingredient-rich hardwoods require specialist wood oils:

- Iroko

- Sapele

- Cherry

- Ipe

- Merbau

- Ebony

- Wenge

- Ipe

- Cork

- Sycamore

- Olive

For interior woods, use Osmo Wood Wax Finish Clear Extra Thin. Exterior wood surfaces, including those below, are compatible with either Osmo UV-Protection Oil or Osmo Decking-Oil, depending on vertical or horizontal installation, and some after an initial weathering period.

- Bankirai

- Bongossi

- Cumaru

- Elm

- Fir

- Garapa

- Massaranduba

- Ponderosa Pine

- Ipe

- Robinia/Locust

- Tali

- Thermowood Pine

- Western Red Cedar

What Wood Finishes Can Be Used Over Wood Oil?

Few to none! Most wood varnishes cannot be applied to oiled wooden surfaces, as the varnish cannot adhere to the surface, or penetrate the oil coating.

Fire retardant varnishes and paints can also not be applied directly to oiled or waxed wood. To paint over wood that has previously had oil or wax on it, the surface must be thoroughly prepared to remove all traces by a combination of sanding and then cleaning. See our blog on fire protection for wood.

What Should I Do Before Applying Finishes?

Preparation

Existing waxes, varnishes, and oils must be sanded back to the original wood, and surfaces must also be clear of contaminants such as grease, dirt, and dust. Holes, dents, and defects should also be filled at this stage, allowed to dry before sanding back level. Rawlins Paints stocks a wide range of general surface cleaners and wood fillers, as well as oil and tannin removers, that help speed up the process of pre-cleaning and preparing your wooden surface.

Sanding Methods

Osmo recommend sanding carefully, choosing a coarse sandpaper contingent on wood condition, on a trial area before preparing your surface.

The following advice is guidance only – refer to our technical team on 0113 2455450 (option 2) or send a message to [email protected] should you require more help.

Before brush or roller application – most likely applies to flooring

- P100-120: for ingredient-rich hardwood species

- P120: provides best results for most wood species

- P150: for softwood species

Before cloth application – most likely applies to furniture and joinery

- P180: for ingredient-rich hardwood species prior to a cloth application

- P200-240: for most wood species prior to a cloth application

Pre-Treatment

Wood finishes achieve just that – finish. They help protect wood surfaces from physical damage, such as abrasion, and weathering, including UV light. Colour or stain your wood before applying your finish, unless it is an all-in-one product.

Why is my wood surface still sticky after applying wood oil?

Sticky surfaces as well as unexpectedly long drying times are often because of over-application of wood oil. Drenching wood in oil, or multiple thick coats, will not aid penetration. It leaves oil sat on top of the wood, attracting dust and dirt and lint, taking much longer to dry. Once cured, it can be damaged much more easily due to not penetrating the wood surface and wear much faster.

This concludes our guide to wood oils; if you have a question not covered in this post then feel free to leave a comment below and we will endeavour to answer your queries as quickly as we can.

Rawlins Paints Blog Industrial Paint Tips, Guidelines & DIY Articles

Rawlins Paints Blog Industrial Paint Tips, Guidelines & DIY Articles

Hi,

I’ve used danish oil as a coating on an oak table, but after many months it still picks up ink from having the morning newspaper spread out on it. Any suggestions? Perhaps a hard wax oil top coat?

Good morning Joseph,

We have not heard of this type of effect happening with any of the Danish Oils we supply. For example the Blackfriar Danish Oil does dry completely to a hard finish, there are no ingredients which might remain tacky. A hard Wax Oil may not make much difference but you could try it. Otherwise Blackfriar Polyurethane Varnish in satin finish could be tried. This should go over the Danish Oil no problem. Clean the surface first by removing any newspaper ink using a methylated spirits. Apply 1 coat of the Polyurethane varnish. Protect the coating from newsprint etc for a full 5 days to ensure the coating has fully cured.

Best regards.

Mark

Hi,

I’m making a pair of doors for a beach hut using sweet chestnut. The hut is south facing and obviously exposed to the elements although slightly protected as it is on the Solent. I’m thinking of oiling the doors. Is this sensible and if so which product would you recommend?

Many thanks,

J-G

Good morning,

Many apologies for the delayed response. If you are still looking for a product for this project, we recommend Osmo UV-Protection Oil.

If there’s anything else we can help you with, please do let us know.

Best regards.

Mark

Which oil should I use on tropical hardwood (unknown which) windows (exterior). They were already installed in the house I bought ten years ago and had been treated with something ….. I’ve not applied anything since but they’ve begun to look worse and worse. Sun and weather created bad stains – combination of deteriorated earlier oils/varnishes, and fungal. I’ve now heavily wire brushed them and they look much better (most stains removed) but are totally bare. WHAT shall I put on them to preserve? if anything?

Good morning Serena,

Apologies for the delayed response. We would recommend Osmo UV-Protection Oil to achieve what is required.

Is there anything else we can help you with today?

Best regards.

Mark