- There are no more items in your cart

- Shipping Calculated at checkout

- Sub-Total (inc. VAT) £0.00

A fire rated, single-component, moisture-curing, low-modulus elastic joint sealant for linear joints in interior and exterior walls and floors. Designed for fire rated movement and connection joints on porous and non-porous substrates, providing up to 4 hours fire resistance according to EN 1366-4.

- Good adhesion to many different substrates

- Very good resistance to weathering

- Can be used down to −40°C

- Movement capability of ± 35% (ASTM C 719)

Sikasil-670 Fire is a fire rated, 1-component, moisture-curing, low-modulus elastic joint sealant. Designed for fire rated movement and connection joints on porous and non-porous substrates, Sikasil-670 Fire provides up to 4 hours fire resistance according to EN 1366-4, with good adhesion to many different substrates and very good resistance to weathering.

Sika now offer a Fire Stopping Solution Finder - a useful tool when needing assistance on specifying fire stopping solutions.

| Packaging | Colour | Article Code | Minimum Order Quantity |

|---|---|---|---|

| 300 ml Cartridge, 12 pc/box | Concrete Grey | 582754 | 112 x boxes of 12 (1344 units total) |

| 300 ml Cartridge, 12 pc/box | White | 483479 | 112 x boxes of 12 (1344 units total) |

| 600 ml Foil, 12 pc/box | Black | 585146 | 60 x boxes of 12 (720 units total) |

Quick Links - Click To Jump To Section:

- Features & Benefits

- Approvals & Standards

- Technical Information

- Joint Design

- Surface Preparation

- Backing

- Application Information

- Application Instructions

- Fire Resistance Configurations

- Further Documents

- Limitations

Features & Benefits

- Fire rated joint sealant

- One-component

- Moisture-curing

- Low-modulus elastic

- Up to 4 hours fire resistance according to EN 1366-4

- Good adhesion to many different substrates

- Very good resistance to weathering

- Can be used down to −40°C

- Movement capability of ± 35% (ASTM C 719)

- Sika now offer a Fire Stopping Solution Finder - a useful tool when needing assistance on specifying fire stopping solutions

Approvals & Standards

- EN 15651-1 F EXT-INT CC 25 LM

- EN 15651-4 PW INT

- ISO 11600 F 25 LM & G 25 LM

- ASTM C 920, class 35

- EN 1366-4 assessment report

- ETA (ETAG 026)

- UL listing (UL 2079)

- EN 13501-2 classification report

- EN 140-3

- LEED v4 EQc 2: Low-Emitting Materials

- ETA acc. EAD-350141-00-1106

- BS 476-20

- UL 2079

- Certifire

- EN 10140-2

Technical Information

| Product Information | |

|---|---|

| Shore A Hardness | ~20 (after 28 d) (ISO 868) |

| Secant Tensile Modulus | ~0.30 N/mm2 at 100 % elongation (23°C) (ISO 8339) |

| ~0.50 N/mm2 at 100 % elongation (−20°C) | |

| Elongation at Break | ~650% (ISO 37) |

| Elastic Recovery | ~70% (ISO 7389) |

| Tear Propagation Resistance | ~4.0 N/mm (ISO 34) |

| Movement Capability | ± 25% (ISO 9047) |

| ± 35% (ASTM C 719) | |

| Service Temperature | −40°C min. / +150°C max. |

Joint Design

The joint width must be designed to suit the joint movement required and the movement capability of the sealant. The joint width shall be ≥ 10 mm and ≤ 40 mm. The joint depth shall be ≤ 20 mm. A width to depth ratio of 2:1 must be maintained (for exceptions, see table below).

| Standard joint widths for joints between concrete elements: | ||

|---|---|---|

| Joint distance [m] | Min. joint width [mm] | Min. joint depth [mm] |

| 2 | 10 | 10 |

| 4 | 15 | 10 |

| 6 | 20 | 10 |

| 8 | 30 | 15 |

| 10 | 35 | 17 |

All joints must be correctly designed and dimensioned in accordance with the relevant standards, before their construction. The basis for calculation of the necessary joint widths are the type of structure and its dimensions, the technical values of the adjacent building materials and the joint sealing material, as well as the specific exposure of the building and the joints.

For larger joints, please contact Sika/Rawlins Technical Support on 0113 2455450 (option 2) or send a message to [email protected].

Surface Preparation

The key to good sealant adhesion is a clean surface! You must always check with the supplier of the substrate to ensure that the cleaning procedures and products are compatible with the substrate.

To ensure good adhesion the substrate must be clean, dry, sound and homogeneous, free from oils, grease, dust and loose or friable particles. Depending on the condition of the surface, porous substrates may require abrasion steps in addition.

Backing

Sikasil-670 Fire may adhere to only two sides of the joint in order to perform properly. The bottom surface of the sealant must be free to deform. If the bottom of sealant adheres, the sealant will rupture during deformation. Backing rods are used to avoid adhesion to the joint’s bottom and to limit its depth.

In most cases, closed cell PE backers are used in combination with Sikasil-670 Fire – For specific cases, refer to the relevant classification reports, ETA’s or similar.

To provide sufficient backpressure during sealant application, the backing rod should be ~25% larger than the joint width. Sizing differs among backing rod types; refer to the manufacturer’s recommendations.

Product Application

IMPORTANT: The sealant must fill the entire joint or cavity and be in full contact with the joint sides. If the joint is improperly filled, good adhesion will not be achieved, and the joint’s performance will be weakened.

Application Information

| Consumption | ||

|---|---|---|

| Joint width [mm] | Joint depth [mm] | Joint length [m] per 600 ml foil pack |

| 10 | 10 | 6 |

| 15 | 10 | 4 |

| 20 | 10 | 3 |

| 25 | 12 | 2 |

| 30 | 15 | 1.3 |

| Information | |

|---|---|

| Backing Material | Use polyethylene foam backing rods. |

| Sag Flow | ~2 mm (20 mm profile, 50°C) (ISO 7390) |

| Ambient Air Temperature | 5°C min. / 40°C max. |

| Substrate Temperature | 5°C min. / 40°C max., min. 3°C above dew point temperature |

| Curing Rate | ~2 mm/24 hours (23°C / 50% r.h.) (CQP 049-2) |

| Skin Time | ~25 min (23°C / 50% r.h.) (CQP 019-1) |

| Tooling Time | ~20 min (23°C / 50% r.h.) (CQP 019-2) |

Application Instructions

Substrate Preparation

The substrate must be clean, dry, sound and homogeneous, free from oils, grease, dust and loose or friable particles. Sikasil-670 Fire adheres without primers and/or activators.

Application Method/Tools

Sikasil-670 Fire is supplied ready to use.

After the necessary substrate preparation, insert a suitable backing rod to the required depth and apply any primer if necessary.

Insert a foil pack or cartridge into the sealant gun and extrude Sikasil-670 Fire into the joint making sure that it comes into full contact with the sides of the joint and avoids any air entrapment.

Sikasil-670 Fire sealant must be firmly tooled against the joint sides to ensure adequate adhesion. It is recommended to use masking tape where exact joint lines or neat lines are required. Remove the tape within the skin time. Do not use tooling products containing solvents.

Cleaning of Tools

Clean all tools and application equipment immediately after use with Sika Remover-208. Once cured, residual material can only be removed mechanically. For cleaning skin use Sika Cleaning Wipes-100.

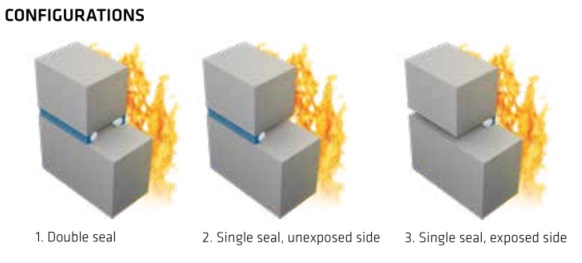

Fire Resistance Configurations

Resistance to fire of vertical linear seals in rigid walls (wall thickness ≥ 150 mm) sealed with Sikasil-670 Fire. Tested acc. EN 1366-4 and classified acc. EN 13501-2/EAD 350141-00-1106.

| Substrates | Movement | Configuration | Joint width (mm) | Joint depth (mm) | Resistance Class |

|---|---|---|---|---|---|

| Concrete* / Concrete | ± 25% | 1 | 12 - 50 | 0.5 x width | EI 240 |

| ± 25% | 2 | 10 - 30 | 15 | EI 45, E 180 | |

| ± 25% | 2 | 12 - 50 | 0.5 x width | EI 30, E 240 | |

| ± 25% | 3 | 10 - 30 | 15 | EI 45, E 60 | |

| ± 25% | 3 | 30 - 50 | 0.5 x width | EI 45, E 60 | |

| ± 7.5% | 1 | 12 - 50 | 0.5 x width | EI 240 | |

| ± 7.5% | 2 | 30 - 50 | 0.5 x width | EI 60, E 240 | |

| ± 7.5% | 3 | 10 - 30 | 15 | EI 60, E 240 | |

| ± 7.5% | 3 | 30 - 50 | 0.5 x width | EI 45, E 180 | |

| Concrete* / Steel | ± 7.5% | 1 | 12 - 30 | 0.5 x width | EI 60, E 240 |

| ± 7.5% | 1 | 30 - 50 | 0.5 x width | EI 90, E 240 | |

| ± 7.5% | 2 | 12 - 50 | 0.5 x width | EI 15, E 240 | |

| Concrete* / Softwood | ± 7.5% | 1 | 12 - 50 | 0.5 x width | EI 120 |

| ± 7.5% | 2 | 12 - 50 | 0.5 x width | EI 90 | |

| Concrete* / Hardwood | ± 7.5% | 1 | 12 - 30 | 0.5 x width | EI 180 |

| ± 7.5% | 1 | 30 - 50 | 0.5 x width | EI 240 |

*Brickwork, concrete or aerated concrete with a density ≥ 760 kg/m

Resistance to fire of horizontal linear seals in rigid walls (wall thickness ≥ 150 mm) sealed with Sikasil-670 Fire. Tested acc. EN 1366-4 and classified acc. EN 13501-2/EAD 350141-00-1106.

| Substrates | Movement | Configuration | Joint width (mm) | Joint depth (mm) | Resistance Class |

|---|---|---|---|---|---|

| Concrete* / Concrete | ± 25% | 1 | 12 - 50 | 0.5 x width | EI 180, E 240 |

| ± 25% | 2 | 12 - 50 | 0.5 x width | EI 60, E 120 | |

| ± 25% | 3 | 10 - 30 | 15 | EI 45, E 60 | |

| ± 25% | 3 | 30 - 50 | 0.5 x width | EI 45, E 60 | |

| ± 7.5% | 1 | 12 - 50 | 0.5 x width | EI 240 | |

| ± 7.5% | 2 | 12 - 50 | 0.5 x width | EI 60, E 240 | |

| ± 7.5% | 3 | 10 - 30 | 15 | EI 60, E 180 | |

| ± 7.5% | 3 | 30 - 50 | 0.5 x width | EI 60, E 90 |

*Brickwork, concrete or aerated concrete with a density ≥ 760 kg/m

Resistance to fire of linear seals in rigid floors (floor thickness ≥ 200 mm) sealed with Sikasil-670 Fire. Tested acc. EN 1366-4 and classified acc. EN 13501-2/EAD 350141-00-1106.

| Substrates | Movement | Configuration | Joint width (mm) | Joint depth (mm) | Resistance Class |

|---|---|---|---|---|---|

| Concrete* / Concrete | ± 25% | 1 | 12 - 50 | 0.8 x width | EI 180, E 240 |

| ± 25% | 2 | 12 - 50 | 0.8 x width | EI 60, E 240 | |

| ± 25% | 3 | 12 - 50 | 0.8 x width | EI 60, E 90 | |

| ± 7.5% | 1 | 12 - 50 | 0.8 x width | EI 240 | |

| ± 7.5% | 2 | 12 - 30 | 0.8 x width | EI 120, E 240 | |

| ± 7.5% | 2 | 30 - 50 | 0.8 x width | EI 60, E 240 | |

| ± 7.5% | 3 | 10 - 30 | 24 | EI 60, E 240 | |

| ± 7.5% | 3 | 30 - 50 | 0.8 x width | EI 60 | |

| Concrete* / Steel | ± 7.5% | 1 | 12 - 50 | 0.8 x width | EI 60, E 240 |

| ± 7.5% | 2 | 12 - 50 | 0.8 x width | EI 60, E 90 | |

| ± 7.5% | 3 | 12 - 50 | 0.8 x width | EI 60, E 90 |

*Brickwork, concrete or aerated concrete with a density ≥ 760 kg/m

Further Documents

- EN 13501-2 classification report

- ETAG 026 assessment report

Limitations

- Sikasil-670 Fire cannot be overpainted.

- Colour variations may occur due to exposure to chemicals, high temperatures and/or UV-radiation (especially with the colour shade white). However, a change in colour is purely of aesthetic nature and does not adversely influence the technical performance or durability of the product.

- Do not use Sikasil-670 Fire on natural stone.

- Do not use Sikasil-670 Fire on bituminous substrates, natural rubber, EPDM rubber or on any building materials which might bleed oils, plasticizers or solvents that could attack the sealant.

- Do not use Sikasil-670 Fire to seal joints in and around swimming pools.

- Do not use Sikasil-670 Fire for joints under water pressure or for permanent water immersion.

- Do not expose uncured Sikasil-670 Fire to alcohol containing products as this may interfere with the curing reaction.

IMPORTANT FIRE PRODUCTS NOTICE: The information displayed on this website should be used as a guide ONLY and our Technical Department should be contacted to obtain a tailored specification and any advice necessary before you place an order for fire protection products. Fire protection products are non-returnable except in accordance with Condition 8 of the Terms and Conditions and should be applied only by an individual with the necessary expertise and experience. We will not be held liable for any resulting damage to property, human life or monetary costs incurred due to the incorrect specification you have prepared or use of fire protection products caused by your negligence, including your failure to have contacted us to obtain the relevant advice/specification.

Data sheet

- Manufacturer

- Sika

- For Use By

- Professional Use

- Interior / Exterior Use

- Interior & Exterior

- For Use On

- Linear Joints

- Application Method

- Sealant Gun

- Pack Size

- 600ml foil pack

300ml cartridge - Max. Application Temperature

- 40°C

- Min. Application Temperature

- 5°C

- UN Number

- N/A

- Fully Cured (at 23°C)

- 24 hours

- Suitable For Use On

- Linear Joints

- Application Method

- Sealant Gun

- Manufacturer

- Sika

- Usages

- Construction

- Product Usage Type

- Fire and Acoustic Protective Seals

- Product Range

- Sikasil

Questions

Question about the product

Be the first to ask a question about this product!

IMPORTANT SHIPPING & DELIVERY INFORMATION

Sikasil-670 Fire Rated Elastic Joint Sealant is only available with the shipping and delivery timescales listed below - please do not contact our Customer Support Team with enquiries about alternative or earlier shipping and delivery times.

Saturdays and Sundays, as well as Bank Holidays, are not classed as working days.

Orders placed after the cut-off for this product will not be processed for earliest dispatch until 9am the next working day.

All delivery costs below are excluding VAT