- There are no more items in your cart

- Shipping Calculated at checkout

- Sub-Total (inc. VAT) £0.00

Need Help?

Fire and Cavity Barriers

Buy fire barriers for use within buildings and wall cavities, at Rawlins Paints. Our range of fire stopping protection for cavities and constructions helps to slow the spread of fire or smoke, aiding evacuation and preventing further fire damage to buildings.

If you require more help to find and specify fire protection for your project or contract, our technical team are always on hand to advise. Give us a call on 0113 2455450 (option 2) or send a message to [email protected].

Subcategories

Tenmat FF102 Ventilated Fire Barriers

Designed to reinstate fire resistance performance within external wall cavities that require permanent (open-state) ventilation in non-fire conditions. It is essential that the correct fire barriers are specified and installed, therefore before you can place your Cavity Barrier order please fill in the application form by clicking on the...

Tenmat Cavguard 65 Cavity Fire Barrier Roll

Designed to reinstate fire resistance performance within external wall cavities, that require permanent ventilation (in non-fire conditions).Provides fire resistance performance within external wall cavities, for periods up to 60 minutes* Suitable for masonry and brickwork external substrates only Ventilated design – developed to allow...

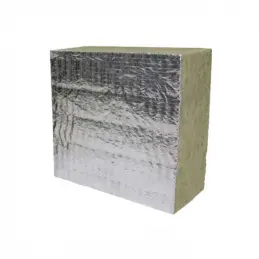

Nullifire FJ220 Intubatt 3 Cavity Barrier

A rock fibre compressible slab, with an ablative coating to provide a fire and smoke seal. Supplied pre-configured, ablative coated and factory cured.Choose from 2 options:Single coated for horizontal seals Double coated for vertical sealsLow cost and simple install Easy to cut Fully identifiable using Optifire Can offer an...

Nullifire FJ240 Spanatherm

Fire resistant rock fibre expansion joints for slab edging and curtain walling, preventing the spread of smoke and fire.Up to 2 hours fire integrity Vapour and smoke barrier Allows significant movement accommodation 1200 x 600 x 100mm slabsPlease contact our technical team on 01132455450 for custom size requirements

Astroflame Clad Ventilated Cavity Fire Barriers

Prevents fire spread and provide compartmentalisation in the external façade. Astroflame fire-rated cavity seals maintain ventilation under normal conditions but expand in a fire to seal the cavity and prevent fire spread. Astro Clad Ventilated Fire Barriers provide essential compartmentalisation for external façades. Before use, all cavity...

Firefly Phoenix Flexible Smoke & Flame Barrier

Lightweight flexible fire rated smoke and flame barrier designed to provide compartmentation within a building offering 120 minutes integrity only, when tested to BS476 Parts 20 & 22.Designed to work as part of a fire protection system and does not provide insulation properties Third Party Certification by IFCC 1418 Exceeds the...

Firefly Apollo Lite 30

Designed to provide compartmentation of larger concealed spaces (extensive cavities) within a building. By offering 30 minutes integrity and 30 minutes insulation, Apollo Lite exceeds the minimum requirements relating to Fire Barriers as detailed in the UK Building Regulations: Approved Document B (Fire Safety).Manufactured using specially...

FSi Paraflam SEB Cavity Barrier

A perimeter barrier designed for curtain walling, a non-combustible stone wool based product with a foil facing which prevents fibre migration and provides an excellent seal.Dry fit (no cure time required) Easy friction fit system High speed installation Lightweight Testing in voids up to 590mm Provides smoke seal Minimal waste...

Nullifire FJ260 Cavity Barrier

Nullifire FJ260 Cavity Barrier is a close state cavity barrier made of rock mineral wool and designed to maintain the required fire resistance around windows, doors and when following fire compartment lines. It is essential that the correct fire barriers are specified and installed, therefore in order to make a purchase you must fill in the...

Firefly Zeus Lite 90

Designed to provide compartmentation of larger concealed spaces (extensive cavities) within a building. By offering 90 minutes integrity and 30 minutes insulation, it exceeds the minimum requirements relating to Fire Barriers as detailed in the UK Building Regulations: Approved Document B (Fire Safety).Manufactured using specially treated...

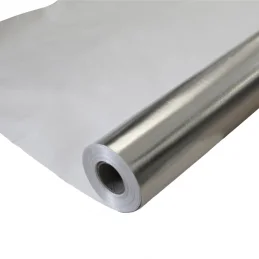

Firefly Membrane WP Breathable Barrier A2 Class

A non-combustible, fire resistant membrane achieving an A2 Non-Combustibility classification in accordance with the demanding EN 13501-1 standard. It is constructed from a strong, durable woven glass substrate aluminised on one side. It is a barrier with excellent mechanical properties and is designed to be a vapour permeable layer or...

Firefly Titan Lite 120

Designed to provide compartmentation of larger concealed spaces (extensive cavities) within a building. By offering 120 minutes integrity and 60 minutes insulation, it exceeds the minimum requirements relating to Fire Barriers as detailed in the UK Building Regulations: Approved Document B (Fire Safety).Manufactured using specially treated...

Firefly Zeus Horizontal 60

Designed to provide compartmentation of larger concealed spaces (extensive cavities) within a building. By offering 60 minutes integrity and 30 minutes insulation, Zeus Horizontal exceeds the minimum requirements relating to Fire Barriers as detailed in the UK Building Regulations: Approved Document B (Fire Safety).Manufactured using...

Firefly Membrane NB Non Breathable Barrier A2 Class

Premium quality fire resistant non-breathable membrane. Made from a strong, durable woven glass substrate laminated to aluminium foil, it is a non-breathable, weatherproof barrier with excellent mechanical properties designed to be an impermeable water barrier or reflective insulation layer in commercial wall applications.A2 Class membrane...

Rockwool PWCB Cavity Barrier

Manufactured from non-combustible stone wool, encapsulated within a resilient polythene sleeve which eliminates the need for weather protection during installation.Fire resistance up to 60 minutes (EI) Can be used in both vertical and horizontal applications, providing an effective fire, acoustic and thermal barrier within external wall...

Firefly Phoenix Horizontal

Lightweight flexible fire rated smoke and flame barrier designed to provide compartmentation within a building, offering 60 minutes integrity only, when tested to BS476 Parts 20 & 22. Certified by IFCC, Firefly Phoenix Horizontal exceeds the minimum requirements of UK Building Regulations: Approved Document B (Fire Safety) for integrity...

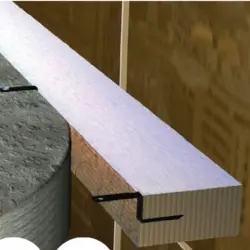

Tenmat NVFB Non-Ventilated Fire Barrier

Designed to maintain fire resistance performance within external wall cavities. For use at: Compartment Floor, Compartment/Party Walls & Around Openings Price on application - please contact our technical team on 0113 2455450 (option 2) or send a message to [email protected] with your project requirements.UL-EU 3rd Party...

Tenmat VFB Plus Ventilated Fire Barrier

“Open state” cavity fire barriers designed to offer fire resistance performance within external wall cavities that require permanent (open-state) ventilation in non-fire conditions. Price on application - please contact our technical team on 0113 2455450 (option 2) or send a message to [email protected] with your project...

Silverliner Open State Cavity Barrier

Developed to protect the voids between the outer façade and the inner construction element of the building. Designed for use in a ventilated façade, the Silverliner OSCB allows for 25mm or 50mm linear air gap to ensure movement of air and drain any moisture within the facade. The aluminium foil restricts fibre migration and offers a class ‘0’...

Firefly Apollo Horizontal 30

Designed to provide compartmentation of larger concealed spaces (extensive cavities) within a building. By offering 30 minutes integrity and 30 minutes insulation, 30:30 exceeds the minimum requirements relating to Fire Barriers as detailed in the UK Building Regulations: Approved Document B (Fire Safety).Manufactured using specially...

Rockwool Fire Barrier System

Developed to prevent the spread of flames and inhibit heat and smoke through concealed spaces in buildings and improve sound reduction. It is comprised of stone wool and has a galvanised wire mesh which is stitched to one side.Fire resistance of up to 2 hours and suitable for void heights of up to 10.5 metres, supported by a stitched wire...

Rockwool TCB Cavity Barrier

Manufactured from non-combustible stone wool, encapsulated within a resilient polythene sleeve which eliminates the need for weather protection during installation.Fire resistance up to 60 minutes (EI) Can be used in both vertical and horizontal applications, providing an effective fire, acoustic and thermal barrier within external wall...

Astroflame Clad Ventilated Cavity Fire Barriers - Specification Received

Prevents fire spread and provide compartmentalisation in the external façade. Astroflame fire-rated cavity seals maintain ventilation under normal conditions but expand in a fire to seal the cavity and prevent fire spread. Astro Clad Ventilated Fire Barriers provide essential compartmentalisation for external façades. Before use, all cavity...

Nullifire FV050 Small Ventilated Cavity Barrier

Suited to an open state cavity of up to 50mm, manufactured from a directionally expansive intumescent material encapsulated in a foil barrier. It is essential that the correct fire barriers are specified and installed, therefore in order to make a purchase you must fill in the application form by clicking on the button below. Our technical...

Nullifire FV025 Small Ventilated Cavity Barrier

Suited to an open state cavity of up to 25mm, manufactured from a directionally expansive intumescent material encapsulated in a foil barrier. It is essential that the correct fire barriers are specified and installed, therefore in order to make a purchase you must fill in the application form by clicking on the button below. Our technical...

Nullifire FV065 Small Ventilated Cavity Barrier Roll

A fire rated product designed to be used as a cavity barrier up to 65mm cavity within external walls. It is essential that the correct fire barriers are specified and installed, therefore in order to make a purchase you must fill in the application form by clicking on the button below. Our technical team will then contact you with the...

Nullifire FV125 Large Ventilated Cavity Barrier

Suited to an open state cavity with a maximum air gap of 25mm and consists of a specially formulated fire rated rock mineral fibre section with an integral high expansion intumescent seal attached to the leading edge. It is essential that the correct fire barriers are specified and installed, therefore in order to make a purchase you must...

Nullifire FV225 Large Ventilated Cavity Barrier

Suited to a ventilated cavity with a maximum air gap of 25mm and consists of a specially formulated fire rated rock mineral fibre section with an integral high expansion intumescent seal attached to the leading edge. It is essential that the correct fire barriers are specified and installed, therefore in order to make a purchase you must fill...

Nullifire FV144 Large Ventilated Cavity Barrier

Nullifire FV144 Large Ventilated Cavity Barrier is suited to an open state cavity with a maximum air gap of 44mm and consists of a specially formulated fire rated rock mineral fibre section with an integral high expansion intumescent seal attached to the leading edge. It is essential that the correct fire barriers are specified and installed,...

Tenmat VFB 60/60

’Open state’ cavity fire barriers for ventilated cavities of up to 450mm. Each VFB 60/60 consists of a specially formulated fire rated stone mineral wool section with an integral high expansion intumescent seal fixed to the leading edge.3rd Party Certification - IFC Certification Typical Fire Ratings of minimum 60 Minutes Integrity and...

Tenmat VFB 120/120

An ’Open State’ cavity fire barrier system for ventilated cavities of up to 450mm. Consists of a specially formulated fire rated stone mineral wool section with an integral high expansion intumescent seal fixed to the leading edge.120 minutes integrity and insulation fire rating for up to 300mm cavities90 Minutes Integrity and...

Firefly Titan Lite Horizontal 90

A flexible fire barrier designed to provide compartmentation of larger concealed spaces (extensive cavities) within a building. By offering 90 minutes integrity and 60 minutes insulation, it exceeds the minimum requirements relating to Fire Barriers as detailed in the UK Building Regulations: Approved Document B (Fire Safety).Manufactured...

Firefly Athena 60

A lightweight, flexible fire barrier, fully certified 60 minutes on timber*. It is designed to be installed as a two-layer fire barrier system, certified for use on timber to provide compartmentation of larger spaces. Exceeds the Fire Barrier requirements of Building Regulations: Approved Document B (Fire Safety) with 60 minutes Integrity and...

Need Help?

Need Help?

What are Fire Barriers and Cavity Barriers?

Fire barriers are structural components used to compartmentalise different sections of a building. These barriers are essential for passive fire protection, meaning they do not require any mechanical or electronic activation to function. Fire barriers can be made from various materials, including fire-resistant boards, fire-rated glass, and intumescent products. They are strategically placed within walls, floors, and ceilings to prevent the spread of fire and smoke from one part of the building to another. Their primary function is to maintain the integrity of the fire compartments, thereby limiting the spread of fire and allowing safe evacuation of occupants.

Cavity barriers, on the other hand, are specific types of fire barriers designed to stop the spread of fire within concealed cavities of buildings. These cavities can be found in places like external wall cladding systems, roof voids, and between floors. Cavity barriers are essential because fire can travel unseen through these hidden spaces, bypassing other fire-resistant elements of the building. Materials used for cavity barriers often include intumescent products that expand when exposed to heat, effectively sealing off the cavity to block the passage of fire and smoke.

What is the primary purpose of Fire Barriers and Cavity Barriers?

The primary purpose of both fire barriers and cavity barriers is to control the spread of fire and smoke within a building, allowing time for safe evacuation and limiting damage to the structure. Fire barriers are intended to contain the fire within a designated compartment, usually for a specific period, ranging from 30 minutes to four hours, depending on the building's design and regulatory requirements.

Cavity barriers are particularly important because they prevent fire from spreading through concealed voids that could otherwise allow fire and smoke to bypass fire-resisting walls and floors. This helps to maintain the integrity of fire compartments, even in areas where fire might travel undetected. By stopping the spread of fire within these hidden spaces, cavity barriers play a crucial role in preventing catastrophic failures in building safety.

Where are Cavity Barriers and Fire Barriers Typically Used?

These locations highlight the importance of fire and cavity barriers in maintaining the fire safety of a building by limiting the spread of fire and smoke through critical areas and concealed spaces.

Fire Barriers:

Structural Elements of the Building:

- Walls (Particularly Compartment Walls): Fire barriers are used within walls to compartmentalise the building, preventing the spread of fire between different sections.

- Floors and Ceilings: Fire barriers are installed in floors and ceilings to maintain compartmentation across different levels of the building.

Service Penetrations:

- Around Pipes, Cables, and Ductwork: Fire barriers are used to seal around services that penetrate through compartment walls and floors. This prevents fire and smoke from passing through these openings.

Firefighting Shafts and Stairwells:

- These areas are critical for safe evacuation and firefighting operations, and fire barriers are used to maintain their integrity during a fire.

Building Envelope:

- External Walls: Fire barriers are installed in external walls to prevent fire from spreading through the building’s façade.

- Curtain Walling and Cladding Systems: These systems often incorporate fire barriers to prevent the spread of fire within the cavities created by cladding systems.

Fire Doors and Industrial Shutters:

- Fire-resistant doors and shutters, which act as fire barriers, are installed to block fire and smoke from moving between compartments within the building.

Cavity Barriers:

Cavities within External Walls:

- Cavity barriers are used in the gaps within external walls, particularly in cladding systems, to prevent fire from spreading vertically and horizontally through these concealed spaces. Both ventilated and non-ventilated cavity barrier options are available, depending on the requirement and fire strategy.

Roof Spaces:

- Cavity barriers are installed in roof voids and between roof levels to stop fire from spreading through these often large, open cavities.

Suspended Ceilings:

- Cavity barriers are used above suspended ceilings to prevent fire from moving through the ceiling voids and reaching other areas of the building.

Service Ducts and Shafts:

- Cavity barriers are placed within service ducts and shafts to prevent fire from spreading through these vertical and horizontal pathways.

How do Fire Barriers and Cavity Barriers differ from each other?

Fire Barriers: Fire barriers are typically part of the main structural elements of a building, such as walls, floors, and ceilings. They are designed to withstand the effects of fire for a specific duration, providing both integrity and insulation to prevent fire and heat from passing through. These barriers are critical for maintaining the structural stability of a building during a fire and ensuring that the fire does not spread from one compartment to another.

Cavity Barriers: Cavity barriers are installed in less visible, often hidden, spaces within a building's structure, such as within external cladding systems, roof voids, and between floors. Unlike fire barriers, cavity barriers are not structural components but are instead installed specifically to block off these concealed spaces. They are essential for preventing the lateral and vertical spread of fire through cavities, which could otherwise compromise the fire safety of the entire building.

What materials are used in Fire Barriers and Cavity Barriers?

Fire Barriers: Fire barriers can be constructed from a variety of materials depending on their intended use and the level of fire resistance required. Common materials include:

- Fire-resistant boards: These are often made from calcium silicate, gypsum, or cementitious materials. They are used in walls, ceilings, and floors to provide a fire-resistant layer.

- Fire-rated glass: Special types of glass that can withstand high temperatures and prevent the spread of fire and smoke.

- Intumescent products: These are materials that expand when exposed to heat, forming an insulating barrier that protects the underlying structure from fire.

- Fire-resistant doors and hardware: These include doors, frames, and fittings that have been tested and rated to withstand fire for a specific duration.

Cavity Barriers: Cavity barriers are usually made from materials that can expand or swell when exposed to heat, effectively sealing off cavities to prevent the spread of fire. Common materials include:

- Intumescent seals: These are strips or blocks of material that expand to fill gaps and voids in cavities when exposed to high temperatures.

- Non-combustible mineral wool: Often used in conjunction with intumescent products, mineral wool provides an additional layer of fire resistance within cavities.

- Rigid fire-resistant boards: These can be installed within cavities to block fire and smoke.

Are there any specific standards for Fire Barriers and Cavity Barriers?

Yes, both fire and cavity barriers must comply with specific fire resistance standards to ensure they perform as expected during a fire. These standards vary by region but often include both British Standards (BS) and European Standards (EN).

- British Standards (BS 476): This series of tests evaluates the fire resistance of materials, including their ability to withstand fire, prevent spread, and maintain structural integrity. For example, BS 476 Part 20 to 24 covers different aspects of fire resistance testing, including walls, floors, and ceilings.

- European Standards (BS EN): These standards are used across Europe to assess fire resistance. For instance, EN 1364-1 covers the fire resistance of non-load-bearing elements such as walls and ceilings, while EN 1366 covers the fire resistance of service installations, including ducts and cavity barriers.

These standards dictate the performance levels required for fire barriers and cavity barriers, ensuring that they provide adequate protection in the event of a fire.

How are Fire Barriers and Cavity Barriers tested?

Fire barriers and cavity barriers undergo rigorous testing to evaluate their performance in a fire. The testing process includes:

- Integrity Testing: This tests whether the barrier can prevent flames and hot gases from passing through. The integrity of the barrier is measured by observing if any gaps or holes form during the test that would allow fire to breach the barrier.

- Insulation Testing: This measures the ability of the barrier to prevent the transfer of heat. The unexposed side of the barrier must not exceed a specific temperature increase during the test period, ensuring that heat does not spread to adjacent areas.

- Load-Bearing Capacity (for structural fire barriers): This tests whether the barrier can maintain its structural function during a fire without collapsing.

Cavity barriers are tested to ensure they can expand or seal off cavities effectively when exposed to fire, preventing the spread of flames and smoke through hidden spaces.

Can existing Fire Barriers and Cavity Barriers be upgraded?

Yes, existing fire barriers and cavity barriers can often be upgraded to improve their fire resistance, but this must be done carefully and in accordance with strict guidelines. Upgrading typically involves the application of additional fire-resistant coatings or the installation of intumescent products.

Key considerations for upgrading include:

- Compatibility: Any upgrades must be compatible with the existing materials and construction methods. Incompatibility can lead to reduced effectiveness and potential failure in the event of a fire.

- Testing: Upgraded barriers should be tested to ensure they meet the required fire resistance standards. This may involve laboratory testing of a sample or in-situ testing of the installed upgrade.

- Certification: Ideally, upgrades should be carried out using certified products and by qualified professionals to ensure compliance with relevant fire safety regulations.

Upgrading fire barriers and cavity barriers can be a cost-effective way to improve fire safety in existing buildings, but it requires careful planning and execution.

What role do Fire Barriers and Cavity Barriers play in building regulations?

Fire and cavity barriers are critical components of a building’s fire safety strategy and are often mandated by building regulations. These regulations ensure that buildings are designed and constructed to provide a reasonable level of safety for occupants in the event of a fire.

Building regulations typically require:

- Fire compartmentation: Fire barriers are used to create compartments within a building, limiting the spread of fire and allowing safe evacuation routes.

- Cavity protection: Cavity barriers are required in specific locations, such as within external wall systems, to prevent fire from spreading through concealed spaces.

- Compliance with standards: Fire and cavity barriers must meet specific fire resistance standards, which are often detailed in national building regulations and guidelines.

Failure to comply with these regulations can result in severe penalties, including fines and the requirement to undertake costly remedial work. Furthermore, non-compliance can significantly increase the risk of fire spreading, potentially leading to loss of life and property.

What is the importance of third-party certification for Fire Barriers and Cavity Barriers?

Third-party certification is a process by which an independent body assesses and verifies that fire and cavity barriers meet the required performance standards. This certification provides confidence that the barriers will perform as expected in the event of a fire.

Benefits of third-party certification include:

- Independent verification: Certification by an independent body ensures that the product or system has been rigorously tested and meets all relevant standards.

- Quality control: Certified products are subject to ongoing surveillance and testing, ensuring that they continue to meet performance standards over time.

- Regulatory acceptance: Many building regulations and insurance companies require or prefer the use of certified products, as they offer a higher level of assurance regarding fire performance.

In summary, third-party certification is an essential component of fire safety, providing assurance that fire and cavity barriers will perform reliably when needed.

Fire Protection Systems

Passive Fire Protection involves built-in fire protection measures that do not require any activation or manual operation during a fire. These systems are integrated into the structure of the building and are designed to contain fire and smoke, allowing time for occupants to evacuate and for emergency services to respond.

Key Components of Passive Fire Protection:

Fire Barriers:

- Definition and Function: Fire barriers are walls, floors, or ceilings that are constructed to resist the passage of fire for a specified period. They are designed to compartmentalise the building, effectively containing fire and smoke to the area of origin.

- Materials and Construction: Fire barriers are made of materials that have been tested and certified for fire resistance. These include fire-rated walls, floors, and ceilings that are constructed using materials such as gypsum, concrete, and fire-resistant glass.

- Integration with Building Structure: Fire barriers must be integrated with the building’s structural elements, such as beams and columns, to ensure that the integrity of the compartmentation is maintained during a fire.

- Importance in Fire Safety: The primary purpose of fire barriers is to protect escape routes and limit the spread of fire, which is critical in large or complex buildings.

Cavity Barriers:

- Definition and Function: Cavity barriers are designed to prevent the spread of fire and smoke through concealed spaces within the building structure, such as wall cavities, roof voids, and underfloor spaces. These barriers block the passage of fire in areas that are typically hidden from view.

- Design and Materials: Cavity barriers are usually made from fire-resistant materials such as mineral wool, intumescent products, or fire-resistant boards. They are designed to expand when exposed to heat, sealing off cavities and preventing the spread of fire.

- Installation and Requirements: The correct installation of cavity barriers is crucial. They must be placed at strategic points, such as the junctions of walls, floors, and roofs, to ensure that all potential pathways for fire spread are blocked.

- Challenges in Implementation: Ensuring that cavity barriers are correctly specified and installed can be challenging, especially in buildings with complex designs or where the construction involves various materials and techniques.

Importance of Proper Installation and Maintenance

The effectiveness of fire and cavity barriers depends heavily on proper installation and regular maintenance. Any gaps or breaches in these barriers can significantly compromise their ability to contain fire and smoke, potentially leading to catastrophic consequences.

In conclusion, Fire Barriers and Cavity Barriers are critical components of a building's fire protection system, designed to limit the spread of fire and smoke, protect occupants, and preserve the structural integrity of the building. Their proper implementation and maintenance are essential for effective fire safety management.

Fire Resistance

Classifications

Fire resistance is a key concept in the protection of buildings from fire and is defined by the ability of a building's elements to withstand fire for a specific period, thereby helping to contain and control the spread of fire and smoke. The classifications for fire resistance are typically broken down into three primary categories: Load Bearing Capacity, Integrity, and Insulation.

1. Load Bearing Capacity:

- This refers to the ability of a building's structural elements (such as steel, concrete, or timber frames) to maintain their load bearing function during a fire. For instance, unprotected steel can lose significant strength at around 500-600°C, potentially leading to structural collapse. The inclusion of passive fire protection measures can extend the load bearing capacity during a fire, ensuring the structure remains intact for the required duration.

2. Integrity:

- Integrity is the ability of a structure to prevent the passage of flames and hot gases through any gaps or openings that could lead to the spread of fire. This is especially important for fire barriers and cavity barriers. A fire barrier or cavity barrier must maintain its integrity to stop fire from breaching compartment walls or floors, especially in concealed spaces. Penetrations through these barriers, such as those for pipes or cables, must also be properly sealed to prevent fire spread.

3. Insulation:

- Insulation refers to the ability of a barrier to prevent the transfer of heat to the non-fire side. This is crucial to prevent the ignition of materials on the unexposed side of a fire barrier or cavity barrier. For example, a fire-resistant wall must keep the temperature on the unexposed side low enough to prevent combustion of adjacent materials, thus ensuring the compartmentalisation of the fire.

Fire Testing and Certification

Fire testing and certification are critical processes that ensure fire barriers and cavity barriers meet the required safety standards. These processes involve rigorous testing under controlled conditions to assess the performance of fire protection products.

1. Fire Testing:

- Standard Fire Tests: Fire barriers and cavity barriers are subjected to standard fire tests to determine their fire resistance. These tests assess how long a barrier can withstand fire while maintaining its load bearing capacity, integrity, and insulation. The results of these tests are used to classify the fire resistance of the barrier, typically expressed in minutes (e.g., 30, 60, 90, or 120 minutes).

- Testing for Different Conditions: It is important to test fire barriers and cavity barriers in various conditions that mimic their intended use in buildings. For example, a cavity barrier installed in a drylining system may behave differently than one in a masonry wall, and therefore, both configurations need to be tested to ensure reliable performance.

2. Product Certification:

- Third-Party Certification: After testing, fire barriers and cavity barriers may undergo third-party certification. This process involves an independent evaluation by a certification body, which may include reviewing test data, assessing the consistency of product performance, and conducting factory audits. Third-party certification provides assurance that the product will perform as expected in a fire.

- Assessment and Expert Judgment: In cases where full-scale testing of all possible configurations is impractical, assessments or expert judgments may be used. These are conducted by qualified fire consultants or accredited laboratories to extend the application of test results to similar configurations. However, these assessments must be carefully scrutinised, especially in light of lessons learned from incidents like the Grenfell Tower fire, which highlighted the importance of accurate and reliable fire performance data.

3. Regulatory Requirements:

- Compliance with Building Codes: Fire barriers and cavity barriers must comply with national building codes, which define the required fire resistance ratings for different building types and uses. In the UK, for example, the relevant fire resistance classifications and testing standards are outlined in documents like Approved Document B.

- Quality Control and On-Site Application: Ensuring that fire barriers and cavity barriers are correctly installed is as important as their initial testing. Incorrect installation can undermine the effectiveness of these barriers, making adherence to manufacturer instructions and quality control protocols essential during construction.

Fire resistance classifications and fire testing and certification processes are crucial for ensuring that fire barriers and cavity barriers provide the intended protection in the event of a fire. These systems must be rigorously tested, correctly installed, and appropriately certified to ensure they function effectively under fire conditions.