- There are no more items in your cart

- Shipping Calculated at checkout

-

Sub-Total (inc. VAT)

£0.00

Need Help?

Anti-Condensation Paints

Anti-condensation paints are advanced coatings designed specifically to address the issue of condensation on interior surfaces. These paints can work in a number of ways from incorporating unique insulating materials that create a thermal barrier, to having millions of micropores to absorb surface moisture preventing the formation of condensation. These coatings reduce the likelihood of moisture accumulating on walls and ceilings, which can lead to dampness, peeling paint, and mould growth. These paints are particularly useful in environments with high humidity levels and fluctuating temperatures, such as bathrooms, kitchens, and various industrial settings. Anti-condensation paints not only enhance the longevity of the painted surfaces but also contribute significantly to indoor air quality and overall structural health. Click for more info.

N-Virol Suretherm Goodbye Mould Thermal Anti Condensation Paint

Anti Condensation Paint ideal for use on cold walls and ceilings in your home or office which may be susceptible to condensation, mould and heat loss. Other uses include steel frame buildings, metal cladding, garage roofs, shipping containers and as part of an underfloor heating system. For internal use only on walls and ceilings - Helps...

Tikkurila GrafoTherm

1-component water-based anti-condensation coating for steel roofing sheets, steel structures and other metal surfaces, where condensation and dripping-water problems occur. It is also suitable for mineral walls and ceilings. Matt Finish. Excellent moisture absorbing and evaporation properties. Forms an elastic, strong film - Insulates...

SmartSeal ClimaShield Anti-Condensation Paint

10 unique colours in a matt finish. For use on interior walls and ceilings. Reduces condensation build-up and prevents black spot mould. Samples available.

Coo-Var Anti-Condensation Paint

White anti-condensation paint. For surfaces prone to condensation, such as walls and ceilings in kitchens, bathrooms, and utility rooms. Durable, matt finish. Biocidal, prevents mould buildup.

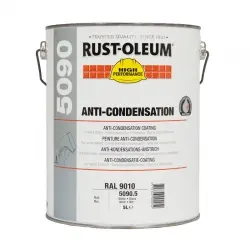

Rust-Oleum 5090 Anti-Condensation Coating

Available in White. Water-based hygienic topcoat. Protects against condensation. For use in breweries, kitchens, wash and shower rooms. Fast drying. Can be applied on slightly damp surfaces. Professional use only.

Resimac Resichem 560 Thermal Barrier XF

High build solvent-free low emissivity coating designed to eradicate condensation build up on cold water lines and can be used on hot process surfaces to reduce the touch surface temperature. Typical applications include pipelines, external tank surfaces, evaporators, separators, pumps, valves, process equipment. For professional use only

Tikkurila Grafotherm Line

1-component water-borne anti-condensation coating for line application. Excellent moisture absorbing and evaporation properties. Prevents from condensation and dripping water, insulates from heat (λ = 0.085 W/mK). Forms very elastic and strong film. Recommended to be used for steel roofing sheets for interior and sheltered premises....

Need Help?

Need Help?

Understanding Condensation

Condensation is a natural process where warm, moist air meets a cooler surface, causing the moisture in the air to turn into liquid water. This phenomenon is common in both residential and commercial buildings and is most pronounced during the colder months when indoor heating is prevalent. Prolonged condensation can lead to structural damage and health problems due to the growth of mould and mildew.

Causes of Condensation

Condensation can be attributed to various factors depending on the setting:

Domestic Settings: Everyday activities such as cooking, bathing, and even breathing contribute to increased humidity levels. When the moist air from these activities comes into contact with colder surfaces like windows, walls, and ceilings, condensation occurs. Poor ventilation exacerbates this issue, trapping moisture inside the home.

Commercial Settings: In places like commercial kitchens, communal shower rooms, and laundries, the continuous generation of steam and moisture significantly increases the risk of condensation. These environments often face higher humidity levels due to their operational nature.

Industrial Settings: Factories, warehouses, and buildings with metal cladding are particularly prone to condensation due to significant temperature fluctuations between indoor and outdoor environments. The presence of cold metal surfaces further facilitates condensation.

Areas Most Prone to Condensation

Condensation tends to form in areas where there is a high level of moisture and insufficient ventilation. Understanding these high-risk zones can help in taking targeted measures to prevent condensation:

Bathrooms: Frequent use of hot water for showers and baths generates a lot of steam, which condenses on colder surfaces like mirrors, windows, and tiles.

Kitchens: Cooking activities release steam and moisture into the air, which can condense on walls, windows, and ceilings, particularly in poorly ventilated kitchens.

Bedrooms: Bedrooms can experience condensation, especially during winter months when windows are often kept closed, trapping moisture inside. This is particularly true for rooms with poor insulation or single-glazed windows.

Garages and Basements: These areas are often unheated and have poor ventilation, making them susceptible to condensation, especially during colder months.

Commercial Kitchens and Breweries: The continuous production of steam from cooking and brewing processes makes these environments prone to condensation issues.

Anti-Condensation Paint: How It Works

Anti-condensation paint is formulated to provide protection against condensation forming on the coated surface. This can be achieved by additives including glass microbeads, or other insulating materials that help maintain a higher surface temperature. This thermal barrier keeps the surface temperature above the dew point, thereby reducing the likelihood of condensation forming. Another method is micropores which allow the paint to act like a sponge absorbing moisture when it is formed and then releasing it slowly when the atmosphere allows. Some anti-condensation paints also contain biocides to prevent the growth of mould and mildew, making them doubly effective in managing moisture-related problems.

Other Methods to Reduce Condensation

In addition to using anti-condensation paints, several complementary measures can help manage and reduce condensation:

Improving Ventilation: Installing extractor fans in high-moisture areas such as bathrooms and kitchens, using dehumidifiers, and ensuring good airflow throughout the property by opening windows and using vents.

Using Dehumidifiers: Dehumidifiers help reduce the overall moisture content in the air, making it less likely for condensation to form on surfaces.

Insulating Walls and Windows: Proper insulation, including double-glazing windows and adding insulation to walls, can significantly reduce the occurrence of condensation by keeping surfaces warmer.

Regular Maintenance: Keeping doors, windows, and other building components in good repair to prevent draughts and cold spots, which can lead to condensation.

Seasonal and Structural Considerations

In the UK, condensation issues are particularly prevalent during the autumn and winter months. During these colder periods, the use of indoor heating increases while outdoor temperatures drop, leading to a higher incidence of condensation on cooler surfaces. Buildings with poor insulation, single-glazed windows, and inadequate ventilation systems are especially vulnerable. Structural elements like uninsulated walls and roofs can also contribute to condensation problems, making it essential to consider both seasonal changes and structural integrity when addressing condensation issues.

Health Risks Associated with Condensation

Condensation not only affects the structural integrity of buildings but also poses significant health risks. Damp and mouldy environments, which are often a result of persistent condensation, can exacerbate respiratory problems and allergies. According to the World Health Organization (WHO), exposure to damp and mould increases the risk of respiratory infections, asthma, and other allergic conditions. The UK government has also recognised the health implications of condensation and provides guidelines for maintaining a healthy indoor environment. These health risks underscore the importance of addressing condensation issues promptly and effectively.

Building Materials and Condensation

Different building materials react differently to moisture and temperature changes, influencing their susceptibility to condensation:

- Metal Surfaces: Common in industrial settings, metal surfaces are particularly prone to condensation because they cool down quickly and provide a cold surface for moisture to condense upon.

- Single-Glazed Windows: These windows are poor insulators and often result in condensation during colder weather.

- Concrete and Brick: These materials can also become very cold and are susceptible to condensation if not properly insulated.

- Insulated Materials: Materials such as properly insulated wood and double-glazed windows are less likely to experience condensation, as they maintain a more consistent temperature.

Condensation on and Around Windows and Window Sills

Windows are common sites for condensation because they often represent the coldest surface in a room. Single-glazed windows are particularly prone to this problem due to their poor insulating properties. Condensation typically forms on the interior surface of the glass and can accumulate on window sills, leading to water damage, paint peeling, and mould growth.

Prevention and Management

- Double-Glazing: Upgrading to double-glazed windows can significantly reduce condensation by providing better insulation.

- Window Insulation Films: Applying insulating films to windows can help improve their thermal performance.

- Regular Ventilation: Ensuring proper ventilation by opening windows or using extractor fans helps reduce indoor humidity levels.

- Dehumidifiers: Using dehumidifiers in rooms with high moisture levels can help control condensation on windows.

Condensation on Ceilings and Walls

Condensation on ceilings and walls is a common issue in areas with poor ventilation and high humidity levels, such as bathrooms and kitchens. It can lead to unsightly water stains, paint peeling, and the growth of mould and mildew, which can be hazardous to health.

Prevention and Management

- Improved Ventilation: Installing extractor fans in high-humidity areas helps remove moist air before it can condense on surfaces.

- Anti-Condensation Paint: Applying anti-condensation paint to ceilings and walls provides an additional layer of protection to help prevent condensation formation.

- Insulation: Adding insulation to walls and ceilings can help maintain a consistent surface temperature, reducing the likelihood of condensation.

- Regular Cleaning: Keeping surfaces clean and free of mould spores helps prevent the growth of mould and mildew.

Condensation on Metal and Metal Roofs

Metal surfaces, including roofs, are particularly prone to condensation due to their high thermal conductivity. Metal roofs, often used in industrial and agricultural buildings, cool rapidly when the external temperature drops, leading to condensation on the underside. This can cause water droplets to form and drip onto stored goods or equipment below, leading to corrosion, damage, and potential operational disruptions.

Certain anti-condensation paints can be highly effective for metal surfaces whether by providing a thermal barrier that reduces the temperature differential between the metal surface and the surrounding air or by being there to absorb any moisture as it forms. This helps in preventing condensation from forming in the first place. Regular maintenance and inspection of metal roofs, along with the application of anti-condensation paint, can significantly mitigate these issues.

Condensation Issues in Various Sectors

Public Sector Buildings and Facilities

Public sector buildings, such as schools, hospitals, and government offices, often face condensation issues due to high occupancy levels and varied usage patterns. In schools, for example, condensation can form in classrooms, gymnasiums, and locker rooms due to fluctuations in temperature and humidity levels. Hospitals must maintain strict environmental controls to ensure patient safety, and condensation can compromise these efforts by fostering the growth of harmful mould and bacteria. Government offices, with their large windows and often older structures, are also susceptible to condensation, particularly in meeting rooms and common areas.

Public Use Areas and Communal Buildings

Areas such as community centres, libraries, and leisure centres experience high foot traffic and usage, leading to significant moisture generation. Showers and changing rooms in leisure centres are particularly prone to condensation, which can lead to slippery surfaces and potential safety hazards. Libraries and community centres, which may not always be well-ventilated, can experience condensation on windows and walls, potentially damaging books and other materials.

Commercial Buildings and Establishments

Commercial establishments such as offices, retail stores, and restaurants often struggle with condensation, particularly in areas like restrooms, kitchens, and storage rooms. Restaurants, with their constant cooking activities, generate large amounts of steam, making them prime candidates for condensation issues. Retail stores with large display windows can also experience condensation, affecting visibility and creating maintenance challenges.

Industrial Plants and Food Processing Plants

Industrial facilities, including food processing plants, manufacturing, and packaging plants, face significant condensation challenges. Food processing plants, in particular, require stringent hygiene standards, and condensation can lead to contamination and spoilage. Manufacturing and packaging plants, which often involve processes that generate heat and moisture, need effective condensation management to maintain product quality and worker safety.

Agricultural Sector

In agricultural settings, condensation can be a significant problem in greenhouses, storage facilities, and animal housing. Greenhouses need to maintain specific humidity levels for optimal plant growth, and condensation can disrupt this balance, leading to fungal diseases. Storage facilities for grains and other produce must remain dry to prevent spoilage, and condensation can compromise these conditions. Animal housing, where warmth and humidity levels are high, is also susceptible to condensation, potentially affecting animal health.

Comparison with Other Paints

Understanding the differences between anti-condensation paints and other moisture-related paints can help in choosing the right product for specific needs.

Damp-Proof Paints

Damp-proof paints are designed to prevent the ingress of moisture through walls and floors and are typically used on interior surfaces such as cellars, basements, etc. These paints create a waterproof barrier that stops moisture from penetrating the walls or floors. However, they do not address condensation issues, which occur on the surface rather than from moisture attempting to penetrate through..

Mould-Resistant Paints

Mould-resistant paints contain fungicides to prevent mould growth. While effective in reducing mould in damp areas, they do not prevent condensation directly. Mould-resistant paints are best used in conjunction with other moisture control measures such as dehumidifiers and improved ventilation to address the root cause of dampness and mould.

Anti-Condensation Paints

Anti-condensation paints are specifically formulated to prevent condensation forming on surfaces. This barrier helps to either keep the surface temperature above the dew point, reducing the likelihood of condensation forming or by remaining open to absorb any condensation that should form. By addressing the issue at the surface level, these paints also indirectly help in preventing mould growth by reducing moisture accumulation.

Government Measures and Regulations

The UK government and local councils have implemented various measures to help manage condensation issues, particularly in rental properties:

- Housing Health and Safety Rating System (HHSRS): This system assesses potential risks, including those from condensation and damp, in rental properties. Landlords must ensure their properties meet these standards to provide a safe living environment. Properties that fail to meet the HHSRS standards can be deemed unfit for habitation, compelling landlords to make necessary improvements.

- Minimum Energy Efficiency Standards (MEES): Regulations requiring rental properties to meet specific energy efficiency standards. These standards mandate improvements in insulation and energy efficiency, which can help reduce condensation issues by maintaining more stable indoor temperatures and reducing thermal bridges where condensation is likely to occur.

- Landlord Responsibilities: Landlords are legally obliged to ensure their properties are free from significant damp and condensation issues. They must provide adequate ventilation and heating solutions and make necessary repairs promptly. Failure to address condensation issues can lead to legal repercussions and affect the health and well-being of tenants.

What Condensation Issues Look Like

Identifying condensation problems early can help prevent more serious issues from developing. Here are some common signs of condensation:

- Water Droplets: The most immediate sign of condensation is the presence of water droplets on windows, walls, and ceilings, especially in the morning or after using hot water.

- Damp Patches: Dark, damp patches on walls and ceilings can indicate persistent condensation issues. These patches often feel cold and wet to the touch.

- Peeling Paint and Wallpaper: Moisture can cause paint to blister, peel, and flake off, and can make wallpaper bubble and detach from the walls. These signs are particularly common in bathrooms and kitchens where humidity levels are high.

- Mould and Mildew: The growth of mould and mildew is a serious consequence of condensation. Black spots of mould typically appear on walls, ceilings, around windows, and on other surfaces that remain damp. A musty smell often accompanies mould growth, indicating poor air quality and ongoing moisture issues.

- Rust: In industrial settings, condensation can cause rust on metal surfaces and machinery. This is a significant concern for maintaining the longevity and functionality of equipment.

- Staining: Condensation can leave unsightly water stains on ceilings and walls, which can be difficult to remove and often reappear if the underlying issue is not addressed.

Consequences of Ignoring Condensation

Ignoring condensation issues can lead to a range of problems, affecting both the structure of buildings and the health of their occupants:

- Structural Damage: Persistent condensation can lead to structural problems over time. Moisture can penetrate walls, leading to the deterioration of building materials such as wood, plaster, and brick. This can weaken the structural integrity of a building, resulting in expensive repairs.

- Health Issues: Damp and mouldy environments are linked to various health problems, including respiratory issues, allergies, asthma, and other infections. The spores released by mould can be particularly harmful to individuals with pre-existing health conditions, the elderly, and young children.

- Damage to Interiors: Decorative finishes like paint, wallpaper, and plaster can suffer significant damage from ongoing condensation. This not only affects the aesthetic appeal of a property but also requires frequent maintenance and redecoration, increasing costs.

- Increased Heating Costs: Damp walls and ceilings are less effective insulators, meaning more energy is required to heat a space. This leads to higher heating costs and increased energy consumption.

- Electrical Hazards: Condensation can pose risks to electrical systems, leading to short circuits, electrical fires, or malfunctioning of appliances and systems. This is particularly hazardous in residential and commercial buildings.

- Fungal Growth: Beyond visible mould, prolonged moisture exposure can lead to the growth of fungi, which can further degrade materials and contribute to an unhealthy living environment.

- Property Value: Properties with noticeable damp and condensation issues can suffer a reduction in value. Potential buyers may be deterred by visible signs of condensation and the associated health risks and repair costs.

Comprehensive Anti-Condensation Management

Effective management of condensation involves a multifaceted approach that includes the use of anti-condensation paints and other preventive measures:

- Anti-Condensation Paint: Applying anti-condensation paint is a proactive measure to prevent condensation from forming on walls and ceilings. These paints create a thermal barrier or porous surface, reducing the likelihood of moisture buildup resulting in condensation.

- Ventilation: Improving ventilation through the installation of extractor fans, opening windows, and using dehumidifiers helps reduce indoor humidity levels. Adequate ventilation is crucial in preventing condensation and maintaining healthy indoor air quality.

- Insulation: Proper insulation of walls, ceilings, and windows helps maintain a consistent temperature, reducing the risk of condensation. Insulating materials such as double-glazed windows and cavity wall insulation are particularly effective.

- Regular Maintenance: Regular inspection and maintenance of buildings, including checking for leaks, repairing damaged surfaces, and ensuring proper insulation, are crucial in preventing condensation. Addressing small issues promptly can prevent more significant problems from developing.

- Professional Assessment: For severe cases, consulting with a professional can help identify the root cause of condensation issues and recommend tailored solutions. Professionals can conduct thorough inspections and provide expert advice on the best measures to take.

FAQs About Anti-Condensation Paint

What is anti-condensation paint?

Anti-condensation paint is a specialised coating designed to prevent the formation of condensation on surfaces. It generally works in two ways - one way contains insulating materials that create a thermal barrier, keeping the surface temperature above the dew point and reducing the likelihood of condensation forming. The other is achieved by micropores that form a multi-layer porous film that can absorb moisture and release it slowly like a sponge..

How does anti-condensation paint work?

The most common type of anti-condensation paint works by incorporating insulating additives such as glass beads or microbeads into its formula. These tiny spheres create a thermal barrier that retains heat on the surface, keeping it warmer than the surrounding air and above the dew point. This prevents moisture in the air from condensing into water droplets on the surface, thus reducing condensation. Other types of anti-condensation paint work through technology allowing the dried paint film to soak up any condensation that forms on the surface so instead of it dripping the paint surface can hold the water until the air able to take the moisture back drying the surface of the paint out and allowing the cycle to begin all over again.

Where can I use anti-condensation paint?

Anti-condensation paint can be used in any area prone to high humidity and temperature fluctuations. Ideal locations include bathrooms, kitchens, bedrooms, garages, basements, and any area where condensation frequently forms on walls, ceilings, or metal surfaces. It is also effective in commercial and industrial settings like commercial kitchens and warehouses.

Can anti-condensation paint be overcoated?

Yes, most anti-condensation paints that work via thermal technology can be overcoated with suitable decorative paints without affecting their performance. This allows for aesthetic flexibility while maintaining the paint’s functionality. However paints that work via absorption shouldn’t be over painted.

Is anti-condensation paint effective on metal surfaces?

Yes, some anti-condensation paints are highly effective on metal surfaces, making it suitable for use in industrial settings like warehouses and metal-clad buildings. Metal surfaces are particularly prone to condensation due to their ability to cool rapidly, so be sure to check the product you’re thinking of using is able to be applied to metal surfaces as some aren’t.

Does anti-condensation paint prevent mould?

While its primary function is to prevent condensation, reducing moisture can also help prevent mould growth. Some anti-condensation paints contain biocides that inhibit mould and fungal growth, providing a dual benefit of moisture and mould control.

How long does anti-condensation paint last?

The longevity of anti-condensation paint depends on the type used, environmental conditions during service and the application. Generally, it lasts several years before needing reapplication. Regular maintenance and reapplication as needed can extend its effectiveness, ensuring continued protection against condensation.

Can I use anti-condensation paint in commercial kitchens?

Yes, anti-condensation paint is suitable for use in commercial kitchens and other high-humidity commercial environments. Its ability to withstand steam and moisture makes it ideal for areas where condensation is a persistent problem.

Is it safe to use anti-condensation paint indoors?

Yes, most anti-condensation paints are only intended for application to interior surfaces so are safe for indoor use when applied according to the manufacturer's instructions. Most anti-condensation paints are water-based and have low levels of volatile organic compounds (VOCs), making them safe for use in occupied spaces. Ensure proper ventilation during application to minimise any temporary odour.

Does anti-condensation paint have a smell?

Anti-condensation paint typically has a low odour, especially compared to other types of paint. Any residual smell can be mitigated by ensuring adequate ventilation during and after application. The odour usually dissipates once the paint has fully dried and cured.

Can I use anti-condensation paint on ceilings?

Yes, anti-condensation paint is effective on both walls and ceilings. Applying it to ceilings in bathrooms and kitchens can prevent condensation drips from forming, which is common in high-humidity areas.

What preparation is needed before applying anti-condensation paint?

Refer to the product data sheet you are intending to use for specific details and pay particular attention when applying to metal. In general surfaces should be clean, dry, and free from grease, dirt, mould, etc. Any existing coatings should be humidity resistant and loose paint should be removed, and glossy surfaces should be lightly sanded to ensure proper adhesion. A specific primer may be required prior to application to bare metal surfaces.

How many coats of anti-condensation paint do I need?

Generally, two coats are recommended for optimal effectiveness. Following the manufacturer's instructions on application thickness and drying times is crucial. Multiple coats help to build a sufficient thermal/absorption barrier to prevent condensation.

Can I apply anti-condensation paint myself?

Yes, most anti-condensation paints can be applied by DIY enthusiasts using a brush, roller, or spray equipment. Ensuring proper surface preparation and application techniques will yield the best results. If using spray equipment, follow the manufacturer's guidelines for optimal performance.

What is the drying time for anti-condensation paint?

Drying times vary depending on the product and environmental conditions. Most anti-condensation paints are touch dry within 1-3 hours and fully cured within a few days. Humidity, temperature, and ventilation can affect drying times, so it's important to follow the manufacturer's recommendations. Ensure the environment is kept dry and well ventilated during curing and that the paint is fully cured before bringing things like showers and steam from cooking back into use in the area.

Is anti-condensation paint available in different colours?

Anti-condensation paint is typically available in white and light grey. However, as discussed above, certain anti-condensation paints can be overpainted, allowing for customisation while maintaining the paint’s anti-condensation properties.

What is the coverage area of anti-condensation paint?

Coverage varies by product and technology type so check the product data sheet for details. Factors such as surface texture and porosity can affect coverage. It's essential to calculate the required amount based on the specific area and surface conditions as under application will likely result in reduced and/or poor performance.

Can anti-condensation paint be used on exterior surfaces?

Some formulations are suitable for protected exterior surfaces, but anti-condensation paint is primarily designed for interior use. Consult the product specifications for exterior applications to ensure the paint will perform adequately in outdoor conditions.

How do I clean tools after using anti-condensation paint?

Tools can usually be cleaned with warm water immediately after use. For stubborn residue, a mild detergent may be used. Cleaning tools promptly ensures longevity and maintains their effectiveness for future use. Always check the product data sheet for information.

Where can I buy anti-condensation paint?

Anti-condensation paint is available to buy today Rawlins Paints, where our Technical and Product Support Team have liaised with manufacturers to choose the best products to deal with recurring and problematic condensation problems in domestic and commercial situations.

If you have a question which has not been covered in these FAQs, or have a specific project requirement, please use the search option on the site, this category’s sidebar filter or sub-category links, or contact our Technical and Product Support Team by phone, email or live chat.

What Rawlins’ Customers Say:

Don’t just take our Technical Support Teams’ words for it, here’s what our customers have to say about anti-condensation paint they have purchased from our store:

The information provided above is a basic overview and is intended as general information only. It is not advice, and is given without warranty. You should always refer to the relevant data sheets and our Technical Team prior to purchase or use of any products.