- There are no more items in your cart

- Shipping Calculated at checkout

- Sub-Total (inc. VAT) £0.00

Need Help?

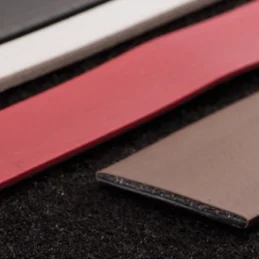

Acoustic and Intumescent Door Seals

Buy intumescent fire and smoke seals for fire doors at Rawlins Paints. These fire-rated seals fit into a rebate to either the eaves or the frame of a fire door to help prevent passage of fire or smoke when the door is closed. This helps contain a fire during an emergency and giving more time for evacuation and for fire and rescue to arrive.

If you require more help to find and specify fire protection for your project or contract, our technical team are always on hand to advise. Give us a call on 0113 2455450 (option 2) or send a message to [email protected].

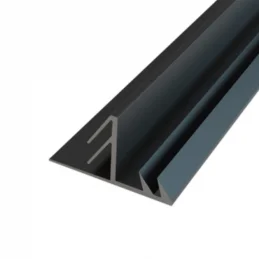

Astroflame Strip Intumescent Fire and Smoke Seals

Intumescent fire and smoke seals for fire door assemblies for fitting into a rebate to either the eaves or the frame of a door. In the event of a fire the seal expands (intumesces) to many times its original volume and seals the gap around the door to provide a safe and effective barrier against the passage of fire, smoke, and hot gases....

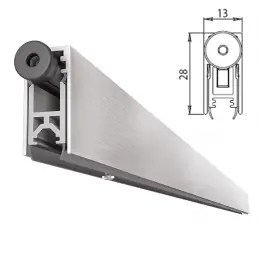

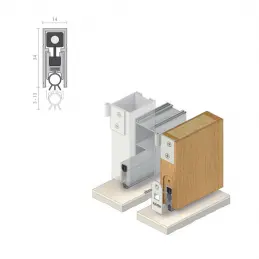

Astroflame ASDB/SM Acoustic Rated Automatic Door Bottom Seals

Automatic door bottom seal which is spring loaded to lift clear of the floor as soon as the door leaf is opened by a few millimetres.Surface Mounted door bottom seal - drop down type Suitable for wooden or metal door assemblies Aluminium body with rubber coextruded seal and carrier Sound reduction of up to Rw 37dB* Suitable for new and...

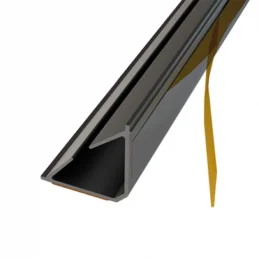

Astroflame ASP Acoustic Smoke & Perimeter Seals

For proprietary fire doors - acoustically and smoke tested.Smoke tested in accordance with BS EN 1634-3: 2004. Suitable for new and retrofit. Easy to install ASP self adhesive seals. Sound reduction: - Up to Rw39dB* (single seal)- Up to Rw35dB* (twin fin).

Pyroplex Timber Door Fire Seals With Pile

A traditional fire, smoke and acoustic seal for fire rated timber door edges and frames. Specifically designed for use in rebates in timber door leafs or door frames, for use on single and double action leaf doors and on latched and unlatched doors, new build and retro-fit applications.Quick and easy to fit with no special tools required...

Norseal Norsound NOR710

Flexible and rigid PVC seals for use around the head and jambs of acoustic and smoke control doorsets.Smoke tested in accordance with BS 476-31.1. Acoustically tested in accordance with BS EN ISO 10140-2. 1,000,000 cycle tested. Certifire CF629 (NOR710). Self-adhesive fixing (NOR710) and kerf-fit (NOR710SR, N710FR). 2100mm length...

Astroflame ASDB/X Acoustic Rated Automatic Door Bottom Seals

Consists of 3 products: ASTRO ASDB SEAL - Rebate Fit Version: An automatic door bottom seal which is spring loaded to lift clear of the floor as soon as the door leaf is opened by a few millimetres.ASTRO ASDBX DB PLUS SEAL - An automatic door bottom seal which is spring loaded to lift clear of the floor as soon as the door leaf is opened by a...

Pyroplex Rigid Box Intumescent Timber Door Fire Seals

Provides a traditional fire only seal for fire rated timber door edges and frames. They are suitable for rebates in single and double action, single or double doors, and are ideal for new build applications.Supplied in 2.1m lengths as standard Quick and easy to fit, with no special tools required Supplied with an acrylic self adhesive...

Norseal Norsound NOR720

TPE seals for use around the head and jambs of acoustic and smoke control doorsets.Smoke tested in accordance with BS 476-31.1 Acoustically tested in accordance with BS EN ISO 10140-2 Certifire CF629 Kerf-fit

Intumescent Seals Therm-A-Seal

Developed primarily for sealing the air-gap between the edges of the leaves and the frames, or between the separate leaves, of both timber and steel fire-resisting door assemblies in the event of a fire.Up to 60 minutes fire and smoke protection Fire resistance in accordance with BS 476-20:22 & BS EN 1634-1 Certifire CF387 approval...

Norseal Corner Seal

An acoustic perimeter seal for use around the head and jambs of acoustic doorsets.Supplied in 2100mm lengths as standard Available in Black, Brown and White Two size options: 12x12mm and 10x10mm Flexible and rigid PVC Self-adhesive Acoustically tested in accordance with BS EN ISO 10140-2 Smoke control tested in accordance with BS...

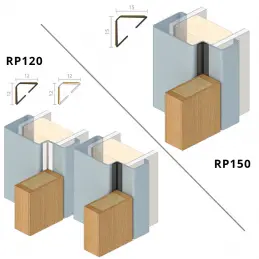

Lorient LAS1206

Medium duty, acoustic and smoke flexible and rigid PVC perimeter seals which minimise the opening and closing resistance of the door leaf due to their unique, curved fins. Flexible elastomeric fin material springs back to original shape to provide ongoing performance and durability in service, that can be fitted with minimal disruption to the...

Norseal Norsound NOR810

Aluminium and silicone gaskets for the bottom edge of acoustic timber doorsets.Suitable for use on most fire doors. Meets smoke requirements BS 8214 (NOR810S, NOR810S+). Compliant with BS 476-22 (NOR810). UL Approval (NOR810). Smoke tested in accordance with BS 476-31.1 (NOR810). Acoustically tested in accordance with BS EN ISO...

Pyroplex Flipper Timber Door Fire Seals

Fire, smoke and acoustic seals for timber door edges and frames. The flippers are thermally fused to the box section to ensure that under normal conditions of use they will not delaminate. This technology ensures improved performance and also the appearance of the seal. The Integral Flipper range adds added security with an integral flipper...

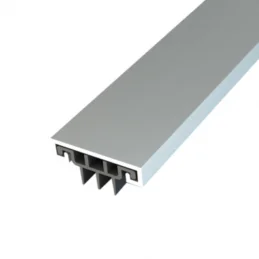

Astroflame Intumescent Aluminium Door Edge Guards

Intumescent and smoke seals fully fire tested up to 1/2 or 1 hours and eliminate the need for repetitive maintenance.Fire tested to BS476 Part: 20 & 22 for 30-60 minutes and EN1634 to 30 mins Eliminate the need for repetitive maintenance Impact protection for both single & double fire doors Suits new & existing fire doors...

Norseal Norsound NOR815

Aluminium with a grey PVC gasket for the bottom edge of acoustic timber or metal doorsets.Draught exclusion and acoustic performance. Meets smoke requirements BS 8214. Screw fixed. Maximum 17mm gap coverage. 300mm cutback (150 from each end).

Sealmaster IMN/IMP Combined Intumescent Doorsets

Fire and smoke resisting (up to 30 minutes) timber doorsets - meeting stiles.Fire tested to BS 476-22 Smoke tested in accordance with BS 476-31.1 Certifire CF462 Mono Ammonium Phosphate Pin every 200mmImportant!Parts are ordered separately from the menu below

Intumescent Seals Therm-A-Blade

Combines the outstanding performance of Therm-A-Flex intumescent with a superb twin blade elastomeric seal for maximum smoke control and improved acoustic properties.Up to 60 minutes fire and smoke protection Provides an alternative to Therm-A-Stop which has a pile smoke seal without compromising the excellent fire performance of...

Lorient LAS1212

Medium duty, acoustic and smoke perimeter seals which minimise the opening and closing resistance of the door leaf due to their unique, curved fins. Flexible elastomeric fin material springs back to original shape to provide ongoing performance and durability in service, that can be fitted with minimal disruption to the door assembly.Use...

Pyroplex Intumescent Door Strips

Provides a basic intumescent seal for fire rated metal and timber door leaves and frames. It is also ideal for general gap filling in buildings eg. suspended floors, soffits and ducting. It can be fitted under door hinges, locks and closers.Ideal for new build and retro-fit applications Supplied in a continuous coil to minimise wastage...

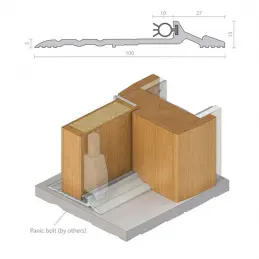

Framefit Door Seal

The ultimate gap remediation system for fire doors for upgrade and correction of gaps around the perimeter of a fire door, a fully tested solution addressing a huge non-compliance issue. FrameFit will not only be a much more cost-effective but will also save many thousands of fire doors from being discarded annually.Tested according to...

Sealmaster N30/N60 Door Seals

30 and 60-minute smoke and fire resistance for timber doorsets - edges and frames.Fixed by pinning every 200mm Fire tested to BS 476-22 Smoke tested to BS 476-31.1 Certifire CF462 Sealmaster N30/N60 are available in 1050mm and 2100mm lengthsMore Information Delivery Info See More Sealmaster

Norseal Norsound NOR850

Aluminium with a black PVC gasket for the bottom edge of acoustic timber doorsets.Smoke tested in accordance with BS 476-31.1. Acoustically tested in accordance with BS EN ISO 10140-2. Screw fixed. Available in 1000mm and 1500mm lengths. Maximum 6mm gap coverage.

Intumescent Seals Therm-A-Stop

Designed for use in fire resisting door assemblies which have been designated as smoke control doors.Reduces flow of air through door assembly, restricts growth of fire by reducing the amount of oxygen available Seal slows spread of smoke and fire through a building Reduces flow of smoke and air through gaps between leaf and frame or...

Norseal Norsound Norfast

Flexible and rigid PVC seals (with graphie section) for use around the head and jambs of fire resisting, acoustic and smoke control doorsets.Fire resistance in accordance with BS EN 1634-1. Smoke tested in accordance with BS 476-31. Acoustically tested in accordance with BS EN 10140-2. Single (SDS) and Double (DDS) doorsets available....

Astroflame Automatic Acoustic & Smoke Rated Door Bottom Seals

Astroflame Automatic Acoustic & Smoke Rated Door Bottom Seals help combat draughts, dust, rain, noise, heat loss, heat gain, fire, smoke and stray light. Designed for areas with a high level of use such as public places such as hospitals, airports, factories, shopping centres or areas with a large flow through of pedestrian and wheeled...

Astroflame Acoustic Smoke & Perimeter Seals

Astroflame Acoustic Smoke & Perimeter Seals include medium-duty seals used in commercial applications such as office spaces, shops, commercial accommodation or medium trafficked areas, and heavy-duty seals designed for areas with a high level of use such as public places such as hospitals, airports, factories, shopping centres or areas...

Astroflame ASMS/DA Meeting Stile Seals

Astroflame ASMS/DA Meeting Stile Seals for single or double doors.High performance seals prevents sound leaks, smoke, dust and light Sound reduction: Up to Rw36dB* Easy to install and supplied with screw fixings Available lengths 2100mm or 2500mm Satin anodised aluminium finishMore Information Delivery Info

Astroflame Smoke Rated Threshold Seals

Astroflame Smoke Rated Threshold Seals include a threshold plate seal (RP97Si) particularly suited for outward opening broad butt hinged plant room and emergency exit doors, and a weather proof threshold plate seal (RP117Si) suited to outward opening broad butt hinged doors.Designed for areas with a high level of use such as public places...

Norseal Norsound NOR820

Norseal Norsound NOR820, aluminium with a grey PVC gasket for the bottom edge of acoustic timber or metal doorsets. Provides smoke and acoustic performance without the removal of timber from the door - fitting of the seal is not detrimental to the doors performance for fire resistance.Meets smoke requirements BS 8214 Acoustically tested...

Lorient LAS1011

Highly effective, flexible and rigid PVC acoustic seals, which also provide additional cold smoke protection around the perimeter of fire rated doors. They can be fitted with minimal disruption to the door assembly.Use Lorient LAS1011 around the head, jambs and at meeting stiles of acoustic and smoke control doorsetsMay also be used at...

Intumescent Seals Therm-A-Flex

Therm-A-Flex will conform to accommodate tight corners, pipes or tubes, and this is one of the factors which ensures its superiority in performance and application when compared with other intumescent strip seals.Up to 60 minutes fire protection Fire resistance in accordance with BS 476-22 Certifire CF387 approval Therm-A-Flex is...

Pyroplex Flexible Timber Door Fire Seals

Provides a permanent seal for fire rated timber and metal door edges and frames, suitable for rebates in timber door leafs or frames or the surface of metal door leafs or frames. 30 and 60 to 90-minute fire resistance options available.Ideal for new build and retro-fit applications Supplied with a coloured polymer cover in a continuous...

Sealmaster Ultima 60 Door Seals

60-minute smoke and fire resistance for timber doorsets - edges and frames.Fixed by pinning every 200mm Fire tested to BS 476-22 Smoke tested in accordance with BS 476-31.1 Certifire CF462 Sealmaster Ultima 60 Door Seals are available in 1050mm lengths, with a milled aluminium colourPlease note: This product is Made To Order with a...

Need Help?

Need Help?

Acoustic and intumescent door seals are integral components of building safety and performance. Acoustic seals are essential for creating soundproof spaces by preventing noise from leaking through door gaps, while intumescent seals are critical for maintaining fire safety by expanding to seal door gaps during a fire, preventing the spread of fire, smoke, and toxic gases.

Both types of seals require careful selection, installation, and maintenance to ensure they perform their intended functions effectively. Understanding the technical specifications, material properties, and regulatory requirements for these seals is crucial for architects, builders, and facility managers responsible for ensuring the safety and comfort of building occupants. By integrating these seals into a comprehensive building safety strategy, it is possible to achieve both enhanced sound insulation and robust fire protection.

Acoustic Door Seals

Functionality and Mechanism

Acoustic door seals play a crucial role in reducing the transmission of sound through door gaps, enhancing the overall sound insulation of a space. These seals are installed around the perimeter of doors, including the bottom, top, and sides, to prevent sound waves from passing through the gaps that typically occur between the door and its frame.

The primary mechanism by which acoustic seals function is by creating an airtight barrier around the door. This barrier disrupts the path of airborne sound waves, reducing their ability to pass through the small gaps that exist around the edges of the door. Additionally, some acoustic seals are designed to absorb sound energy, further enhancing their effectiveness in reducing noise transmission.

Types of Acoustic Seals

Acoustic seals come in various forms, each designed to address specific challenges related to sound transmission:

Perimeter Seals:

These seals are installed around the edges of the door. They compress when the door is closed, forming a tight seal that prevents sound from leaking through the gaps. Perimeter seals are often made from dense, flexible materials such as rubber, silicone, or neoprene, which are known for their durability and sound-absorbing properties.

Automatic Drop Seals:

These are specialised seals installed at the bottom of the door. When the door is closed, the seal automatically drops to close the gap between the door and the floor. This type of seal is particularly effective in preventing sound from leaking through the bottom of the door, which is often the weakest point in door soundproofing.

Brush Seals:

In some applications, brush seals are used to reduce sound transmission. These seals feature densely packed bristles that fill the gap between the door and the frame. While not as effective as solid rubber or silicone seals, brush seals can still provide a moderate level of sound reduction and are often used in conjunction with other types of acoustic seals.

Material Composition

The materials used in acoustic door seals are critical to their performance. Typically, these seals are made from high-density, flexible materials that can withstand repeated compression and decompression without losing their effectiveness. Common materials include:

● Silicone: Known for its flexibility and durability, silicone is often used in acoustic seals for its excellent soundproofing properties and resistance to temperature extremes.

● Neoprene: Another popular material, neoprene offers good sound-absorbing capabilities and is resistant to oil, heat, and weathering, making it suitable for a wide range of applications.

● Rubber: Rubber seals are commonly used due to their ability to form a tight seal. They are also durable and can maintain their performance over time, even with frequent door use.

Some acoustic seals may also incorporate composite materials that combine the properties of different materials to enhance soundproofing while maintaining durability and ease of installation.

Installation and Compatibility

Proper installation is crucial for the effectiveness of acoustic door seals. The seals must be fitted tightly and uniformly around the door to ensure that there are no gaps or misalignments that could compromise their soundproofing capabilities. Installation typically involves attaching the seals to the door or frame using adhesive backing, screws, or clips, depending on the type of seal.

Installation Techniques:

When installing perimeter seals, it's essential to ensure that the seal is continuous around the door’s edges. For automatic drop seals, the installation must ensure that the seal activates correctly when the door is closed and retracts fully when the door is opened.

Compatibility with Door Types:

Acoustic seals are designed to be compatible with various door types, including wooden doors, metal doors, and glass doors. However, the specific type of seal selected may vary depending on the door material and the required level of soundproofing.

Integration with Other Systems:

In some cases, acoustic seals may be integrated with other building systems, such as automatic door closers or access control systems. This integration requires careful planning to ensure that the seals do not interfere with the operation of these systems.

Performance Standards and Testing

Acoustic door seals are tested and rated based on their ability to reduce sound transmission. The effectiveness of these seals is often measured in terms of the Sound Transmission Class (STC) rating, which quantifies the ability of a building element, such as a door, to reduce airborne sound transmission.

Sound Transmission Class (STC):

Higher STC ratings indicate better sound insulation. Acoustic seals contribute to the overall STC rating of a door assembly. The seals are typically tested in conjunction with the door and frame to determine the combined soundproofing performance.

Testing Standards:

Acoustic seals are often tested according to standards such as ASTM E90 (Standard Test Method for Laboratory Measurement of Airborne Sound Transmission Loss of Building Partitions and Elements). This standard specifies the test method for measuring the sound transmission loss of various building elements, including doors with acoustic seals.

Common Applications

Acoustic door seals are widely used in environments where noise control is critical. Some common applications include:

● Recording Studios: In recording studios, even minor sound leakage can compromise recording quality. Acoustic seals are essential in preventing external noise from entering the studio and maintaining a controlled acoustic environment.

● Conference Rooms and Offices: In office buildings, acoustic seals are used to create private spaces where confidential conversations can take place without the risk of eavesdropping.

● Medical Facilities: In hospitals and clinics, acoustic seals help to ensure patient privacy by reducing the transmission of sound between rooms.

● Hotels and Residential Buildings: In multi-unit residential buildings and hotels, acoustic seals are used to reduce noise transfer between rooms, providing occupants with a quieter living environment.

Intumescent Door Seals

Functionality in Fire Protection

Intumescent door seals are a vital component of fire protection in buildings. These seals are designed to expand when exposed to high temperatures, typically during a fire, to fill the gaps around doors and prevent the passage of fire, smoke, and toxic gases. The expansion of the seal creates a barrier that helps to contain the fire within a specific area, allowing more time for occupants to evacuate and for fire services to respond.

Mechanism of Expansion:

Intumescent seals contain materials that undergo a chemical reaction when exposed to heat. This reaction causes the material to expand significantly, often up to 20 times its original size. This expansion is rapid and occurs as the temperature in the vicinity of the seal rises, typically starting around 200°C. The expanded material fills any gaps around the door, sealing them tightly to prevent the spread of fire and smoke.

Fire Resistance and Integrity:

The primary function of intumescent seals is to maintain the integrity of fire-rated doors during a fire. By sealing the gaps around the door, the seals help to ensure that the door continues to act as a barrier to fire and smoke, preserving the compartmentation within the building and preventing the fire from spreading to other areas.

Material Composition and Types

Intumescent door seals are made from materials that are specially formulated to react to heat by expanding. Common materials used in these seals include:

Sodium Silicate:

Sodium silicate is one of the most common materials used in intumescent seals. When exposed to heat, it undergoes a chemical reaction that causes it to swell and form a solid barrier.

Graphite-Based Compounds:

Some intumescent seals use graphite-based materials, which expand when heated. These materials are particularly effective at high temperatures and can form a dense, solid barrier against fire and smoke.

Combination Seals:

In some cases, intumescent seals are combined with other types of seals, such as acoustic or smoke seals, to provide a multi-functional barrier that offers both fire protection and sound insulation.

Installation and Integration

The installation of intumescent door seals is a critical step in ensuring their effectiveness. These seals are typically installed along the edges of fire-rated doors, including the top, sides, and bottom, to create a continuous barrier when the door is closed.

Groove Installation:

Intumescent seals are often installed into grooves cut into the door or frame. This method ensures that the seals are flush with the surface and do not interfere with the door's operation. The depth and width of the grooves must be carefully measured to match the dimensions of the seal.

Compatibility with Fire Doors:

Intumescent seals are designed to work in conjunction with fire-rated doors, which are constructed to resist fire for a specified period (e.g., 30 minutes, 60 minutes). The seals must be compatible with the door's material and construction to ensure that the entire assembly performs as required under fire conditions.

Integration with Other Fire Protection Systems:

Intumescent seals are often used alongside other fire protection measures, such as fire-rated glazing, automatic fire door closers, and smoke control systems. This integration is essential for creating a comprehensive fire protection strategy that maximises the safety of building occupants.

Testing and Certification

Intumescent door seals must undergo rigorous testing and certification to ensure they meet the necessary fire resistance standards. These tests assess the seal’s ability to expand and maintain a barrier against fire and smoke for the required duration.

Fire Testing Standards:

Intumescent seals are typically tested according to standards such as BS 476-20/22 (Fire Tests on Building Materials and Structures) and EN 1634-1 (Fire Resistance Tests for Door and Shutter Assemblies). These standards specify the conditions under which the seals must be tested, including the temperature profile and the duration of the fire exposure.

Third-Party Certification:

To ensure reliability, many intumescent seals are subject to third-party certification. This involves testing by independent certification bodies, such as the British Standards Institution (BSI) or Underwriters Laboratories (UL). These bodies also conduct regular audits of the manufacturing process to ensure consistent product quality.

Field of Application:

The results of fire tests are often limited to the specific configuration tested. For instance, a seal tested with a particular door type and frame may not necessarily be certified for use with different door configurations. Manufacturers often provide a "field of application" document, outlining the specific conditions under which the seal can be used.

Applications in Building Safety

Intumescent door seals are essential components in the fire safety strategy of a building. They are used in various types of buildings, particularly where fire compartmentation is required to contain fire outbreaks within a specific area.

High-Risk Areas:

Intumescent seals are crucial in high-risk areas, such as stairwells, corridors, and escape routes, where maintaining compartmentation is vital for safe evacuation. They are also used in areas where fire compartmentation is required between different floors or zones within a building, such as in large commercial complexes or multi-storey residential buildings.

Regulatory Compliance:

Building regulations in most countries require the use of fire-rated doors and intumescent seals in specific areas of a building. Compliance with these regulations is essential for ensuring the safety of occupants and for meeting legal requirements.

Compatibility with Other Fire Protection Systems:

Intumescent seals are often part of a broader fire protection system that includes fire doors, fire-resistant glazing, and smoke control systems. The seals must be compatible with these other components to ensure that the entire system works effectively in the event of a fire.

Maintenance and Lifespan

To ensure that intumescent door seals remain effective, regular inspection and maintenance are required. Over time, seals can become damaged or degraded, particularly in environments with high humidity, temperature fluctuations, or frequent door use.

Regular Inspections:

Building maintenance personnel should regularly inspect intumescent seals as part of the building’s fire safety programme. Inspections should check for signs of wear, damage, or degradation, such as cracks, brittleness, or detachment from the door or frame.

Replacement of Damaged Seals:

If a seal is found to be damaged or degraded, it must be replaced immediately to maintain the fire resistance of the door assembly. Replacement seals should be identical to the original in terms of material, size, and certification to ensure continued compliance with fire safety standards.

Expected Lifespan:

The lifespan of intumescent seals can vary depending on the specific material and environmental conditions. Manufacturers typically provide guidance on the expected lifespan of their products, as well as any conditions that might affect their performance. In general, well-maintained intumescent seals can last for many years, but they should be periodically reviewed as part of the building’s fire safety management.

FAQs

How do I select the most suitable acoustic seal for my door?

When choosing an acoustic seal, several factors must be considered:

● Door Type and Material: The seal should be compatible with the type of door, whether it's solid, hollow core, or glazed. Solid core doors usually provide better sound insulation.

● Performance Requirements: Determine the level of noise reduction required, usually expressed in decibels (dB). Higher performance seals may include a combination of compression seals, drop seals, and perimeter seals.

● Environmental Conditions: Consider the conditions where the seal will be used, such as humidity, temperature fluctuations, or exposure to chemicals, which may affect the seal's durability.

● Regulatory Compliance: Ensure that the seal meets relevant standards such as BS 476-31.1 for smoke control and BS EN ISO 10140-2 for acoustics.

● Aesthetic and Operational Considerations: Choose a seal that complements the door’s appearance and does not impede the door’s normal operation.

What are the key considerations for installing intumescent door seals to ensure optimal performance?

Proper installation of intumescent door seals is critical for their effectiveness. Key considerations include:

● Correct Sizing and Placement: The seal must fit snugly around the door perimeter, including the door frame and any glazing or panels. It is typically placed in a groove cut into the door or frame.

● Compatibility with Door Hardware: Ensure that the seal does not interfere with locks, hinges, or other door hardware. Intumescent seals are often combined with other fire-rated components to ensure the entire door assembly meets fire resistance requirements.

● Fire Rating: The seal should match the fire rating of the door assembly, typically ranging from 30 minutes (FD30) to 120 minutes (FD120) of fire resistance.

● Adherence to Manufacturer Instructions: Follow the manufacturer's guidelines for installation, including the use of compatible adhesives or fixings and ensuring that the seal is not stretched or compressed during installation.

● Regular Inspection and Maintenance: Intumescent seals should be regularly inspected for signs of wear, damage, or tampering. Any damage could compromise their ability to perform during a fire.

Is it possible to combine acoustic and intumescent door seals, and what should be considered?

Yes, combined acoustic and intumescent door seals are available and commonly used in environments where both sound insulation and fire protection are required. Considerations for combined seals include:

● Performance Testing: Ensure that the combined seal has been tested for both acoustic performance (measured in dB or Rw) and fire resistance (measured in minutes of integrity and insulation).

● Seal Configuration: These seals are often multi-functional, incorporating materials that both expand under heat and block sound transmission. The configuration must allow the seal to perform both functions without compromising on either.

● Compliance with Building Regulations: The seal should comply with relevant building regulations for both fire and acoustic performance. In the UK, this might include Approved Document B (fire safety) and Document E (resistance to the passage of sound).

● Installation Expertise: Installation should be carried out by professionals familiar with both acoustic and fire seal installations to ensure that the dual-functionality is not compromised.

What maintenance practices should be followed to ensure long-term performance of door seals?

Maintenance of door seals is essential to ensure they continue to function effectively. Best practices include:

● Regular Inspections: Periodically inspect seals for any signs of wear, damage, or displacement. Acoustic seals may degrade over time, while intumescent seals should be checked for signs of tampering or damage that could affect their expansion in a fire.

● Cleaning: Keep seals clean and free from dust, dirt, or any foreign objects that could affect their sealing properties. Use appropriate cleaning materials that do not degrade the seal material.

● Lubrication (if applicable): Some acoustic seals, particularly those with moving parts like drop seals, may require occasional lubrication to ensure smooth operation.

● Replacement: Replace seals that show significant signs of wear, have been damaged, or after a fire event (for intumescent seals). Replacement should always be done with seals of equivalent or superior quality and certification.

● Professional Assessment: For fire-rated doors, a professional inspection may be required to assess the condition of both the door and the seals as part of regular fire safety checks.

What certifications and standards should I look for when purchasing door seals?

When purchasing door seals, especially for critical applications like fire protection and acoustic control, certification is vital:

● Fire Resistance Standards: Look for seals that are certified to BS 476 for fire testing in the UK, specifically Parts 20-24 for elements like doors. European standards such as EN 1634-1 for fire resistance and smoke control tests are also commonly referenced.

● Acoustic Standards: Acoustic seals should be certified to standards like BS EN ISO 10140-2, which measures the reduction of airborne sound. A high dB rating is indicative of better sound insulation.

● Third-Party Certification: Seals certified by third-party bodies such as Certifire, which is accredited by UKAS (United Kingdom Accreditation Service), provide additional assurance that the product meets stringent performance criteria. Third-party certification often includes ongoing factory audits and random product testing to ensure consistency.

● Smoke Control: For smoke seals, compliance with BS 476-31.1 or equivalent is essential, ensuring the seal effectively prevents smoke leakage during a fire.

What types of intumescent materials are used in door seals, and how do they differ?

Several types of intumescent materials are used in door seals, each with specific properties:

● Graphite-Based Intumescents: These materials expand rapidly at lower temperatures, making them ideal for applications where quick response is critical. They are often used in high-risk areas such as chemical plants or buildings with high occupancy.

● Sodium Silicate Intumescents: These are slower to expand compared to graphite but provide a strong insulating barrier once activated. They are typically used in standard commercial and residential buildings.

● Hybrid Intumescents: Some seals combine multiple intumescent materials to offer a balance between rapid expansion and strong insulation, providing versatile protection across different environments. The choice of material depends on the specific fire safety requirements of the building, including the expected fire load, the type of construction, and the desired fire resistance duration.