- There are no more items in your cart

- Shipping Calculated at checkout

- Sub-Total (inc. VAT) £0.00

Need Help?

Intumescent Fire Sleeves

Buy intumescent fire sleeves at Rawlins Paints. We have fire-rated sleeves for all manner of services such as pipes (plastic and metal), cables, conduits, air ducts, and more. Suitable for retrofitting as well as new builds, our intumescent fire sleeves expand when attacked by fire, with some products offering up to 240 minutes fire resistance.

If you require more help to find and specify fire protection for your project or contract, our technical team are always on hand to advise. Give us a call on 0113 2455450 (option 2) or send a message to [email protected].

Tenmat FF109 Vent Duct Fire Sleeves Low Profile

CE Marked fire penetration seals designed to firestop PVC ventilation ducts/pipes when installed through fire rated constructions.Fire rated product up to EI 120 minutes Tested for masonry, concrete and plasterboard walls Tested in external wall / SFS constructions Can be installed within Ablative Coated Fire Batts U/U -...

Astroflame Low Profile Intumescent Duct Sleeves

A more compact version of the original Astroflame Duct Sleeve that offers the same industry leading fire performance, maintain the integrity of fire rated walls penetrated by plastic ventilation ducts. In the event of a fire the intumescent material of the duct sleeve expands and crushes the plastic ventilation duct, closing off this route to...

Tenmat FF109 Pipe Fire Sleeves

Designed to reinstate the fire resistance performance of wall and floor constructions where insulated metal or plastic pipes have been installed.CE Marked 4-in-1 Solution - Fire, Acoustic, Thermal and Vapour Seal Up to EI120 Minutes Fire Rating in Gypsum Walls and Solid Floors Up to EI240 Minutes Fire Rated in Solid Walls Assessed for...

Quelfire QRS Intumescent Fire Sleeves

Prevent the spread of fire where plastic ducts penetrate fire compartment walls, for up to 2 hours. Requires no mechanical fixing or framework support, relying on the fire rated wall construction, plasterboard or solid masonry/block (or QuelStop Fire Batt) to hold it in place. Slim version available for applications where there is limited...

Astroflame Thermal Fire Pipe Sleeve

A cost effective solution for the fire stopping of pipe penetrations, e.g. plumbing pipe and metallic pipes, whilst maintaining similar thermal and acoustic properties as standard mineral fibre insulation. These properties ensure compliance to water bye laws and building regulations for cold and hot water pipes and heating systems.CE...

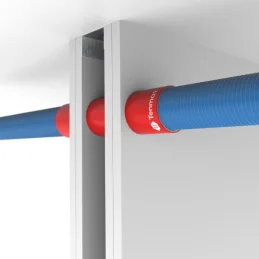

Quelfire QRS Intumescent Slim Fire Sleeves

Prevent the spread of fire where plastic ducts penetrate fire compartment walls, for up to 2 hours (note: QRS220/90SS is rated 60 minutes only). They are specifically designed to be slim for applications where there is limited space around the duct. Requires no mechanical fixing or framework support, relying on the fire rated wall...

Astroflame Intumescent Duct Sleeve

Intended for use where a ventilation duct passes through a fire rated wall, maintaining the integrity of the fire rated wall which would otherwise be lost. In the event of a fire, the advanced Duct Sleeve will expand with the heat, crushing the duct and closing off the hole to the fire for at least 120 minutes except the 220x90mm version which...

Rockwool Fire Tube

A range of simple to install, pre-formed cylindrical sections of non-combustible stone wool to suit standard steel pipe diameters.Designed to provide fire protection of up to 4 hours Fire Tube is suitable for use with structural steel, circular hollow sections (CHS), solid bars, sprinkler pipes and process pipework Available in both...

Nullifire FP220 Service Sleeve

A pipe closer device, comprising of an intumescent material within a stainless steel shell.Expands when exposed to fire, reinstating the fire performance of compartment walls which have been penetrated by combustable pipes Suitable for retrofit or inclusion prior to service installation, PE, HDPE, ABS, San+PVC, PP, PVC-C, UPONOR, DB, MLCP...

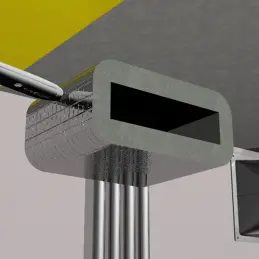

Tenmat Vent Duct OverSleeve

A firestop penetration seal designed to fit around Semi Rigid PE Ducting that pass through fire rated partitions.EI120 Fire Rating Can be retrofitted Low Profile Only one layer required No additional metal sleeving or support required Tested in min. 100mm Drywall / Solid WallsMore Information Delivery Info

Tenmat Oversleeve Pipe Sleeves

A universal, universal, one-product-fits-all solution for the firestopping of combustible and insulated metal pipes.Up to EI240 Minutes Fire Rating Thin/Low Profile (3mm thick) Can be retrofitted One Product Solution - suits a wide range of pipe materials, diameters & insulation types Simple Installation - no fixings, anchors or...

Quelfire QIF Insulated Fire Sleeves

Prevents the spread of fire where combustible (plastic) and non-combustible (metal) pipes penetrate fire compartment walls and floors, for up to 4 hours. Suitable for use in concrete floors and various wall constructions including solid concrete masonry/block walls and flexible fire rated plasterboard partitions with and without QuelStop Fire...

Rockwool Insulated Fire Sleeves

A combination of Rockwool stone wool and graphite intumescent, supplied with a factory applied reinforced aluminium foil facing. Intended for use on copper, steel and most types of plastic pipes, trunking and conduits to provide up to 4 hours* fire resistance. Providing all the Rockwool thermal, noise and fire benefits with an added...

Need Help?

Need Help?

Intumescent fire sleeves are an essential component of passive fire protection, designed to seal penetrations in fire-rated barriers and prevent the spread of fire and smoke. Their effectiveness depends on proper selection, installation, and maintenance, as well as compliance with relevant building regulations and standards. Regular inspection and integration with other fire protection systems are also crucial for ensuring that they perform as expected in the event of a fire. Understanding these aspects is key to implementing a comprehensive fire safety strategy in any building.

Functionality and Purpose:

Intumescent Reaction:

Intumescent fire sleeves are constructed from materials that expand significantly when exposed to high temperatures, typically starting at around 200°C. This expansion process involves the material swelling up and forming a char, which effectively blocks openings around services (e.g., pipes or cables) that penetrate fire-resistant barriers. This charred layer acts as a barrier to fire, smoke, and hot gases, maintaining the integrity of the fire compartment.

Sealing Performance:

These sleeves are particularly effective at maintaining the fire-resisting properties of walls and floors that have been penetrated by services. The intumescent material ensures that the passage of flames and smoke through these openings is prevented, thus protecting adjacent areas and reducing the risk of fire spread.

Application Scenarios:

Intumescent fire sleeves are used in various scenarios, including around plastic and metal pipes, electrical conduits, and other service penetrations in fire-rated partitions. They are essential in buildings where services must pass through compartment walls or floors, such as in commercial buildings, hospitals, and high-rise residential buildings.

Application and Installation:

Correct Installation:

The effectiveness of intumescent fire sleeves depends heavily on proper installation. This includes ensuring the sleeve is correctly sized for the pipe or conduit it surrounds and that it is properly aligned within the penetration. The sleeve must be securely fixed to prevent it from being dislodged during the fire or in normal use, which could compromise its effectiveness.

Installation in Different Building Materials:

The installation process may vary depending on the type of wall or floor construction. For example, installation in a solid concrete wall may require different techniques compared to a lightweight partition wall. The installer must follow the manufacturer’s instructions closely to ensure the sleeve provides the required fire resistance.

Pre-Installation Considerations:

Before installation, it is important to consider factors such as the size and type of the pipe, the thickness of the wall or floor, and the fire resistance rating required. Additionally, the installer should check for any existing fire protection measures that might interact with the sleeve, ensuring compatibility and effectiveness.

Fire Resistance and Testing:

Standards and Certification:

Intumescent fire sleeves are subject to rigorous testing to ensure they meet specific fire resistance standards. These standards typically include BS 476: Part 20/22 (Methods for Determination of the Fire Resistance of Elements of Construction) or EN 1366 (Fire Resistance Tests for Service Installations). The sleeves are tested to assess their performance in conditions that simulate real fire scenarios, ensuring they can maintain their integrity and insulation properties for a specified duration.

Testing Procedures:

During testing, the sleeve is installed around a pipe or conduit, and the assembly is exposed to high temperatures to simulate a fire. The test measures how long the sleeve can prevent the passage of fire and smoke through the penetration. The sleeve’s ability to expand and seal the opening is a critical factor in determining its effectiveness.

Performance Ratings:

Fire sleeves are rated based on their performance in these tests, typically in terms of minutes (e.g., 30, 60, 90, 120 minutes). This rating indicates the duration for which the sleeve can effectively maintain the fire integrity of the penetration. Products are certified based on these results, and this certification must be referenced during installation to ensure compliance with fire safety regulations.

Building Regulations and Compliance:

Regulatory Framework:

The use of intumescent fire sleeves is governed by building codes and standards, such as Approved Document B in the UK. These regulations specify the requirements for fire resistance in various types of buildings and situations. Compliance with these regulations is mandatory to ensure the safety of building occupants and to meet legal obligations.

Specification and Documentation:

Architects and engineers are responsible for specifying the correct type and rating of fire sleeves in construction documents. This includes detailing the fire resistance required for each penetration, based on the building’s use, occupancy, and fire safety strategy. The specification must align with the regulatory requirements for the specific building type and the services being protected.

Third-Party Certification:

Many building projects now require third-party certification of fire protection products, including intumescent fire sleeves. This certification provides assurance that the products meet the necessary standards and have been tested under realistic conditions. Third-party certification is often a prerequisite for construction tenders and is increasingly required by regulatory authorities.

Maintenance and Inspection:

Regular Inspection Requirements:

To ensure ongoing effectiveness, intumescent fire sleeves must be regularly inspected as part of the building’s fire safety maintenance program. Inspections should check for any signs of damage, degradation, or improper installation that could compromise the sleeve’s performance in a fire.

Documentation of Inspections:

It is important to maintain detailed records of all inspections and any maintenance performed on the fire sleeves. This documentation should include the date of inspection, the condition of the sleeves, and any corrective actions taken. Keeping these records is essential for compliance with fire safety regulations and for ensuring that the building’s fire protection systems remain effective.

Responding to Building Changes:

If the building’s use changes, or if alterations are made that affect the services passing through fire-rated barriers, the fire sleeves may need to be re-evaluated and possibly replaced or upgraded. Any modifications to the building should trigger a review of the fire protection measures to ensure they are still appropriate.

Integration with Other Fire Protection Systems:

Part of a Passive Fire Protection Strategy:

Intumescent fire sleeves are a key component of a building’s passive fire protection system. They work alongside other elements such as fire-resistant walls, floors, doors, and seals to contain fire and smoke within a compartment, thereby protecting escape routes and limiting fire damage.

Coordination with Active Fire Protection Systems:

Although fire sleeves are a passive protection measure, they often complement active systems such as sprinklers, fire alarms, and smoke control systems. For example, fire alarms may trigger the closure of fire doors, while the fire sleeves ensure that fire does not spread through service penetrations, providing a comprehensive fire protection strategy.

Interdependencies:

The effectiveness of fire sleeves can depend on the proper functioning of other fire protection measures. For instance, if a fire-rated wall is compromised due to improper maintenance or alterations, the fire sleeves may not be able to perform their intended function effectively. Therefore, the entire fire protection system must be considered holistically, with each component working in unison.

Additional Considerations:

Environmental Factors:

The performance of intumescent fire sleeves can be influenced by environmental conditions such as humidity, temperature fluctuations, and exposure to chemicals. Some intumescent materials are sensitive to moisture, which can affect their ability to expand and seal during a fire. Therefore, it is important to select fire sleeves that are suitable for the specific environmental conditions of the building.

Product Selection:

Different intumescent fire sleeves are available for various applications, such as different pipe materials (plastic vs. metal), sizes, and configurations. Selecting the appropriate product for each specific penetration is critical to ensuring effective fire protection. This selection process should consider the type of service, the fire resistance rating required, and any specific environmental conditions that may affect performance.

Manufacturers’ Instructions:

Adhering to the manufacturer’s instructions is vital for the correct installation and maintenance of intumescent fire sleeves. These instructions provide guidance on installation techniques, environmental considerations, and compatibility with other building materials. Failure to follow these guidelines can result in compromised fire protection and potential non-compliance with building regulations.

FAQs

What are Intumescent Fire Sleeves?

Intumescent Fire Sleeves are a type of passive fire protection device used to maintain the fire resistance of walls, floors, and ceilings that are penetrated by services like pipes, cables, and ducts. These sleeves contain intumescent materials that expand when exposed to heat, sealing gaps and preventing the spread of fire, smoke, and gases through the penetrations.

How do Intumescent Fire Sleeves work?

Intumescent Fire Sleeves operate by reacting to high temperatures typically encountered during a fire. When the temperature reaches a critical level (usually between 150°C and 200°C), the intumescent material within the sleeve expands to form a solid char. This char effectively blocks the pathway through which fire, smoke, and toxic gases could spread, thereby maintaining the integrity of the fire-rated barrier (walls, floors, or ceilings).

Where are Intumescent Fire Sleeves Typically Used?

Intumescent Fire Sleeves are integral to the fire safety strategy of a wide range of buildings. Their primary function is to protect the integrity of fire-rated barriers by sealing service penetrations, thereby preventing the spread of fire, smoke, and toxic gases. Their use is widespread across commercial, residential, industrial, public, and infrastructure buildings, each presenting unique challenges and requirements for fire safety. The correct application of these sleeves is crucial in ensuring that the building’s fire resistance is maintained and that occupants are protected in the event of a fire.

Commercial Buildings

- Office Buildings: In modern office spaces, Intumescent Fire Sleeves are essential for protecting the numerous penetrations made for HVAC systems, electrical conduits, and plumbing. These sleeves help to maintain the fire compartmentation of different floors or sections of the building, ensuring that in the event of a fire, the spread is limited, allowing for safe evacuation and minimal property damage.

- Shopping Centres and Retail Outlets: Retail environments often have complex layouts with multiple service penetrations for heating, ventilation, air conditioning, and electrical systems. Intumescent Fire Sleeves are used to protect these penetrations, particularly in areas with high human traffic where quick and safe evacuation is critical in the event of a fire.

Residential Buildings

- Multi-Story Apartments: In high-rise residential buildings, vertical penetrations for water, gas, and waste pipes between floors are common. Intumescent Fire Sleeves are crucial in these settings to prevent the rapid vertical spread of fire, which could otherwise threaten multiple floors and occupants. The sleeves ensure that fire cannot easily travel through the building via service penetrations, thereby protecting residents and giving them more time to evacuate safely.

- Mixed-Use Developments: Buildings that combine residential, commercial, and sometimes even industrial spaces under one roof present unique challenges for fire safety. Intumescent Fire Sleeves are used here to maintain the fire resistance of walls and floors that separate different usage areas, ensuring that a fire in one section (e.g., a commercial kitchen) does not compromise the safety of residential areas above or adjacent to it.

Industrial Facilities

- Factories and Warehouses: In industrial settings, large-scale HVAC ducts, process piping, and electrical conduits frequently penetrate fire-rated barriers. Intumescent Fire Sleeves are employed to protect these critical penetrations, especially in environments where hazardous materials are stored or used, and where the risk of fire is inherently higher. These sleeves help to contain any fire within a specific area, preventing it from spreading to other parts of the facility and potentially causing significant property damage or risk to life.

- Manufacturing Plants: Particularly in plants with heavy machinery and complex systems, Intumescent Fire Sleeves are used to ensure that fire does not spread through the numerous penetrations required for machine operation, cooling systems, or exhaust ducting. Maintaining the fire resistance of these penetrations is vital for protecting workers and minimising the potential downtime and damage caused by fires.

Public Buildings

- Schools and Universities: Educational facilities often have multiple penetrations through walls and floors for services like communication cables, heating, and plumbing. Intumescent Fire Sleeves are installed to protect these penetrations, ensuring that in the event of a fire, students and staff have sufficient time to evacuate safely. These buildings also often have high occupancy levels, making fire containment and safe evacuation paramount.

- Hospitals and Healthcare Facilities: In healthcare environments, the safety of patients, who may not be able to evacuate quickly, is a primary concern. Intumescent Fire Sleeves are used extensively in these settings to protect service penetrations through fire-rated walls and ceilings. This application is critical in maintaining fire compartmentation, which helps to prevent the spread of fire and smoke, allowing for the safe evacuation of vulnerable individuals and the protection of vital medical equipment.

- Government Buildings: These buildings often contain sensitive information and critical infrastructure. Intumescent Fire Sleeves are used to protect the fire integrity of walls and floors, particularly in areas where electrical and communication services penetrate fire-rated structures. This ensures that in the event of a fire, the damage and spread are contained, protecting both people and assets.

Infrastructure and Transportation Hubs

- Airports and Train Stations: These are large, complex buildings with extensive service penetrations for ventilation, security systems, and passenger services. Intumescent Fire Sleeves are critical in these environments to maintain the fire resistance of walls and floors, especially in areas with high passenger traffic or where critical infrastructure is housed. By containing any potential fire within a specific area, these sleeves help to ensure the safety of large numbers of people and the continued operation of essential services.

What materials can Intumescent Fire Sleeves protect?

Intumescent Fire Sleeves are designed to protect a wide range of materials, including:

- Plastic Pipes: Often vulnerable because they can melt and create openings during a fire.

- Metal Pipes: These can conduct heat, which may compromise fire barriers if not properly sealed.

- Insulated Pipes: Pipes with thermal insulation, where the insulation material may degrade under fire conditions.

- Cables and Conduits: Electrical and communication cables that pass through fire-rated partitions.

What fire ratings do Intumescent Fire Sleeves provide?

The fire ratings for Intumescent Fire Sleeves typically range from 30 to 240 minutes, depending on the specific product and application. These ratings indicate the duration for which the sleeve can effectively maintain the fire resistance of the penetrated structure, ensuring that the fire does not spread through the penetration for the specified time period.

How are Intumescent Fire Sleeves installed?

Proper installation is critical to the effectiveness of Intumescent Fire Sleeves. The general steps include:

- Preparation: Ensure that the opening around the pipe or duct is clean, and the sleeve fits snugly around the service and within the opening.

- Insertion: The sleeve should be inserted into the penetration so that it is flush with the surface of the wall, floor, or ceiling.

- Sealing: Depending on the sleeve design, additional fire-resistant sealant or mechanical fixings may be required to secure the sleeve in place and ensure a complete seal.

- Verification: After installation, it is important to inspect the sleeve to ensure it is properly positioned and there are no gaps or misalignments.

What maintenance is required for Intumescent Fire Sleeves?

Although Intumescent Fire Sleeves are generally low-maintenance, regular inspections should be conducted to ensure they remain effective. Inspections are particularly important after any renovations or alterations that may affect fire-rated penetrations. Any damage or displacement should be addressed immediately by replacing or repairing the sleeve as per the manufacturer's guidelines.

What standards and certifications should Intumescent Fire Sleeves meet?

Intumescent Fire Sleeves should comply with relevant standards, including:

- BS 476 Part 20-24 (UK): This series of standards provides guidelines for fire resistance tests for building materials and structures, including penetration seals.

- EN 1366 (Europe): Specifies fire resistance tests for service installations, including ducts and pipes.

- UL 1479 (USA): Standard for fire tests of through-penetration firestops.

- ASTM E814 (USA): Standard test method for fire tests of penetration firestop systems.

Compliance with these standards ensures that the fire sleeves have been rigorously tested under conditions that simulate real fire scenarios.

Can Intumescent Fire Sleeves be used for retrofitting existing buildings?

Yes, Intumescent Fire Sleeves are suitable for retrofitting in existing buildings. When used in retrofitting applications, it is essential to assess the existing conditions, such as the type of wall or floor construction and the materials used for pipes or ducts. The selected sleeve must be compatible with these conditions to ensure it provides the required level of fire protection.

What factors should be considered when selecting an Intumescent Fire Sleeve?

When selecting an Intumescent Fire Sleeve, several factors need to be considered, including:

- Type of Pipe or Duct: The material (e.g., plastic, metal) and size of the pipe or ducting to be protected.

- Fire Rating Requirements: The fire resistance duration needed based on building regulations or specific project requirements.

- Compatibility: Ensuring the sleeve is compatible with the building’s fire safety strategy and other fire protection measures in place.

- Installation Environment: Consideration of environmental conditions, such as exposure to moisture, chemicals, or extreme temperatures, which may affect the performance of the sleeve.

- Certification and Testing: Ensure the sleeve has been tested and certified by recognized bodies, and review the manufacturer’s data sheets for limitations and installation guidelines.

What is the difference between a fire collar and a fire sleeve?

- Fire Collar:

- Purpose: Designed to seal gaps around plastic pipes in fire-rated walls or floors to prevent fire spread.

- Construction: Metal casing with intumescent material that expands when exposed to heat, closing off gaps if the pipe melts.

- Application: Installed around pipe penetrations in walls or floors; rated for specific durations (e.g., 30, 60 minutes).

- Usage: Used in buildings to maintain compartmentalisation, especially where pipes penetrate fire barriers.

- Fire Sleeve:

- Purpose: Provides continuous fire-resistant protection for pipes, cables, and other services along their length.

- Construction: Made from materials like silicone-coated fibreglass; some are intumescent, while others act as heat barriers.

- Application: Encases cables or pipes to protect them from fire and heat, used in environments needing functionality during a fire.

- Usage: Common in emergency systems, data centres, and industrial settings.

Key Differences:

- Function: Fire collars seal openings around penetrations, while fire sleeves protect the service elements they encase.

- Activation: Fire collars expand to seal gaps when heated, whereas fire sleeves provide passive or intumescent insulation.

- Installation: Fire collars are fixed in place around pipes; fire sleeves slide over cables or pipes.

- Regulatory Testing: Fire collars are tested for maintaining barrier integrity; fire sleeves are tested for protecting cables or pipes during a fire.