- There are no more items in your cart

- Shipping Calculated at checkout

-

Sub-Total (inc. VAT)

£0.00

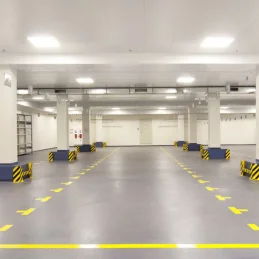

Water-based epoxy floor coating for commercial and industrial use as a decorative or clear dust proof seal on industrial floors in food preparation areas, warehouses, breweries etc, with good abrasion resistance to foot and light wheeled traffic.

- Ronacrete RonaFloor EWB - FeRFA Type 1

- Can be applied to RonaScreed Self Smooth within 3 hours and other Ronacrete screeds within 24 hours

- Adheres well to concrete and granolithic surfaces

- Rapid drying and chemical curing

- Good resistance to a wide range of chemicals including Skydrol and jet fuel

- Can be applied to damp sub-floors and new screeds

- Can incorporate fine aggregate to achieve high slip resistance

- Wide range of decorative colours

- Good wear capability (compared to floor paints) but should not be used in areas where high wear is expected

- For professional and industrial use

Important!

- Tinted colours (RAL and British Standard) have a minimum order quantity of 60KG (12 x 5KG, 4 x 15KG)

Product customisation

Don't forget to save your customization to be able to add to cart.png)

RonaFloor EWB is a 2 part water based epoxy resin floor coating. It has good adhesion to a wide variety of substrates to produce a tough, hard wearing floor finish and is available in an attractive range of colours. RonaFloor EWB Coating does not contain solvents and is therefore more suitable than solvented resins for use in areas where tainting is unacceptable.

Floors coated with RonaFloor EWB show good abrasion resistance to foot traffic and light wheeled vehicles. RonaFloor EWB Coating is used as a decorative or clear dust proof seal on industrial floors in food preparation areas, warehouses, breweries etc.

Quick Links - Click To Jump To Section:

- Features & Benefits

- Substrate Preparation

- Application Conditions

- Substrate Priming

- Mixing

- Application

- Cleaning

- Slip Resistance

- Colour Variation

- Osmotic Blistering

Features & Benefits

- Good resistance to a wide range of chemicals

- Good abrasion resistance to foot and light wheeled traffic

- Can be applied to RonaScreed Self Smooth within 3 hours and other Ronacrete screeds within 24 hours

- Easy to apply

- Rapid drying and chemical curing

- Can be applied to damp sub-floors and new screeds

- Can incorporate fine aggregate to achieve high slip resistance

- Provides decoration; wide colour range

- FeRFA Type 1

Surface Preparation

To achieve maximum adhesion it is essential that RonaFloor EWB is applied to a structurally sound, clean substrate.

Remove all loose material from surface and make good any surface defects by using one of the RonaFloor Repair 1 Hour mortars.

The surface should be free from grease, oil, dirt etc and prepared by light vacuum shot blasting to remove laitance.

The surface should then be vacuumed to remove all dust and debris.

The Relative Humidity at the surface should be below 80% when measured with a hygrometer.

Mixing

Add full contents of hardener container to full contents of resin container and mix with a slow speed drill and spiral mixing paddle until a homogeneous colour is achieved.

Typical mixing time is about 3-4 minutes. Pour the mixed material into a roller tray or onto the substrate.

To avoid transfer of unmixed material to the floor resin must not be taken directly from the mixing vessel by brush or roller.

Application Technique

Apply by short or medium nap mohair or lambswool (not foam) roller. Push the resin well in to the surface making sure the floor is fully wetted and then pull back lightly by roller to the required thickness. Use coverage rates as a guide to thickness. It is important to apply at the specified coverage rate and thickness; if a coat is applied too thin the coating may not properly cure and will have a shortened life expectancy. If applied too thick it may crack and blister.

For slip resistant properties scatter RonaFloor A/S Aggregate Fine Grade within the first coat of RonaFloor EWB and allow to cure. Remove any excess aggregate by brush or vacuum and apply a further 1 or 2 coats of RonaFloor EWB.

On porous and uneven substrates more than two or three coats of RonaFloor EWB may be required. Special attention should be paid to ensure pooling of RonaFloor EWB is avoided in depressed areas.

Do not use where air and substrate temperatures are below 10°C.

Limitations

RonaFloor EWB is normally applied at an overall thickness of 100 microns.

Its wear capability is good compared to floor paints but it should not be used in areas where high wear is expected; RonaFloor HB100 or HB200 should be considered instead. RonaFloor EWB, in common with all other epoxy resin products, will soften when subjected to temperatures of 65℃ and above.

Repeated exposure to high temperature will weaken the product and cause it to debond.

Slight variations in surface colour may be experienced when floor areas are coated in different temperature and atmospheric conditions, this is typical of water based epoxy coatings.

Coverage

Use coverage rates as a guide to thickness. It is important to apply at the specified coverage rate and thickness; if a coat is applied too thin the coating may not properly cure and will have a shortened life expectancy and poor opacity and appearance.

If applied too thick it may crack and blister. The coverage quoted in the Technical Data makes no allowance for substrate texture or porous substrates.

On porous substrates, full opacity may require the application of three or more coats. Actual coverage rates will vary from site to site and can only be accurately determined by site trials and after allowing full cure to take place prior to assessment.

Cleaning

Brushes and tools should be cleaned immediately with water.

Chemical Resistance

Good resistance to a wide range of chemicals including Skydrol and jet fuel. Refer to Ronacrete/Rawlins Technical for advice on 0113 2455450 (option 2) or send a message to [email protected].

Maintenance of Colour Consistency

To achieve optimum performance and appearance in shade and sheen, store and apply RonaFloor EWB at a constant ambient temperature, humidity and with the same air movement throughout the project. Avoid storage and application at air, substrate and material temperatures below 10℃.

Packs of RonaFloor EWB should be used in strict batch rotation. Individual areas or rooms should be treated with material from a single batch to avoid the inevitable minor variations in shade resulting from batch manufacture, otherwise matched batches should be used to minimise these variations (an extract from FeRFA Guide to the Specification and Application of Synthetic Resin Flooring). Minimise these variations (an extract from FeRFA Guide To The Specification And Application Of Synthetic Resin Flooring).

RonaFloor EWB provides a durable and economical decorative coating. Where higher performance is required and where surface appearance is more important, other coatings such as RonaFloor HB100 are recommended.

Osmotic Blistering

In rare instances, osmotic blistering can occur when synthetic resin floor coatings are applied. FeRFA Guidance Note No 2: Osmosis in Resin Flooring provides guidance on steps that can be taken to reduce the risk of osmotic blistering.

Data sheet

- Manufacturer

- Ronacrete

- For Use By

- Professional Use

- Interior / Exterior Use

- Interior Use

- For Use On

- Concrete Floors

Granolithic Floors - Application Method

- Roller

- Single, Two or Three Pack

- Two-Pack

- Pack Size

- 5KG

10KG - Pot Life (at 20°C)

- 1.5-2 hours

- Coverage

- 35-40m² per pack per coat

- Max. Application Temperature

- 25°C

- Min. Application Temperature

- 15°C

- Solids by Volume

- 41.5%

- Touch Dry

- 4-8 hours

- Finish

- Matt

- Layer Thickness

- 100 microns

- Layer Thickness

- Nominal 50µ per coat

- Resistance to chemicals

- Skydrol

- Resistance to chemicals

- Jet Fuel

- Fully Cured

- 7 days

- Colour(s)

- Standard Colours

- Base Type

- Water-Based

- Suitable For Use On

- Granolithic Floors

- Suitable For Use On

- Concrete Floors

- Finish

- Matt

- Application Method

- Roller

- Manufacturer

- Ronacrete

- Usages

- Chemical Resistance

- Product Usage Type

- Topcoat

- Product Range

- RonaFloor

- Foot Traffic

- 24 hours

- Forklift Traffic

- 3 days

- Cleaning

- Water

- Colour Family

- Grey

- Colour Family

- Green

- Colour Family

- Blue

- Colour Family

- Red

- Colour Family

- Yellow

- Colour Family

- Black

- Intercoat Period

- 4-24 hours

- Product Type

- Epoxy

- Product Attributes

- Tintable

Questions

Question about the product

Be the first to ask a question about this product!

IMPORTANT SHIPPING & DELIVERY INFORMATION

Ronacrete RonaFloor EWB is only available with the shipping and delivery timescales listed below - please do not contact our Customer Support Team with enquiries about alternative or earlier shipping and delivery times.

Saturdays and Sundays, as well as Bank Holidays, are not classed as working days.

Orders placed after the cut-off for this product will not be processed for earliest dispatch until 9am the next working day.

All delivery costs below are excluding VAT

Ronacrete RonaFloor HB100

Solvent-free, two-component epoxy floor coating that provides an economical wear resistant surface on concrete and polymer modified screeds. Ronacrete RonaFloor HB100 is available in a range of colours available for decorative appearance and demarcation of zones Apply to RonaFloor Epoxy DPM on drying concrete BS 8204-6 & FeRFA Class 2...

Ronacrete RonaFloor HB200

A FeRFA Class 3 and BS 8204-6, two-component, solvent-free epoxy floor coating for use on concrete and polymer modified screeds. Ronacrete RonaFloor HB200 provides excellent abrasion and chemical resistance to floors subject to constant traffic, suitable for use in chemical plant storage areas, warehousing, toilets, laboratories and food...

Ronacrete RonaFloor A/S Aggregate

Kiln-dried fine and medium anti-slip aggregate for broadcasting into resin flooring systems. Fine grade (0.1-0.3mm) and medium grade (0.4-0.8mm) available Designed to increase the slip resistance of resin surfaces With the addition of 1-2kg per m2 you can achieve a slip resistance value of up to 70 giving extremely low risk of slip...