- There are no more items in your cart

- Shipping Calculated at checkout

-

Sub-Total (inc. VAT)

£0.00

Self-smoothing cementitious wearing screed for industrial floors. The material gains strength quickly and can be accessed by foot traffic in 24 hours.

- Suitable for application to concrete floors from a minimum 5mm thickness to a maximum 20mm

- When applied thinner than 8mm, substrate imperfections will be evident

- For screeds thicker than 20mm, RonaScreed Self Smooth Base may be applied as the initial layer and topped with RonaScreed Self Smoothing Levelling Topping

- Suitable for wet areas

- Conforms to BS EN 13813

- Ronacrete RonaScreed Self Smoothing Levelling Topping - For professional and industrial use

.png)

RonaScreed Self Smoothing Levelling Topping is a flow applied protein free floor topping for industrial floors. The material gains strength quickly and can be accessed by foot traffic in 24 hours.

Quick Links - Click To Jump To Section:

- Features & Benefits

- Achievable Surface Finish

- Preparation

- Priming with RonaFloor Epoxy DPM

- Priming and Sealing with RonaScreed Self Smooth Primer

- Notes

- Mixing/Laying

- Estimating Guide

- Application Temperature

- Joints

- Cleaning

Features & Benefits

- Self smoothing cementitious floor screed

- Self finished industrial floor topping

- Excellent wear resistance

- Up to 1500m2 can be pumped per day depending on thickness

- Ready for foot traffic after 24 hours @ 20ºC

- Quality Assured to ISO 9001

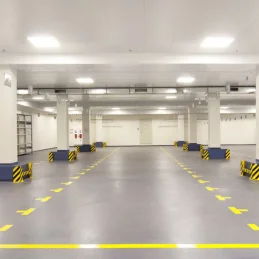

Achievable Surface Finish

Due to the nature of the product the risk of air bubbles, pinholes and surface undulations cannot be entirely eliminated.

Correct substrate preparation, effective sealing and priming and correct mixing/ application will provide optimum results. It is recommended that a Ronacrete Approved Contractor should be employed.

The presence of surface imperfections will not impair the performance of the product. The use of RonaFloor Epoxy DPM to prime the floor is preferred to sealing and priming with RonaScreed Self Smooth Primer; adhesion is improved and the risk of pinholing is considerably reduced.

Preparation

The concrete must be mechanically prepared by vacuum shot blasting or scabbling to fully remove laitance and then cleaned to remove contamination, Loose shot and dust should be removed by vacuum cleaning before the process of sealing and priming commences. Pins may be placed in the floor to set out the required levels.

Priming with RonaFloor Epoxy DPM

Priming of the substrate with RonaFloor Epoxy DPM is the preferred priming method. A single coat of RonaFloor Epoxy DPM is usually sufficient to seal the substrate and provide good adhesion. RonaFloor Epoxy DPM should be applied at the rate of 3.3m2/kg and kiln dried sand (grade 8/16 approximately 0.8-1.4mm applied at the rate of 2.5kg/m2) should be scattered into the wet resin.

Loose aggregate must be removed by vacuum cleaning before application of RonaScreed Self Smoothing Levelling Topping. RonaFloor Epoxy DPM should be allowed to cure for 18-24 hours @ 200℃ before loose aggregate is removed.

Priming and Sealing with RonaScreed Self Smooth Primer

Seal the prepared surface by applying one or more coats of RonaScreed Self Smooth Primer diluted with 5 parts water at the rate of 0.62 litres/m2. Allow to dry for not more than 36 hours; protect the surface and keep clean.

Note that inadequate sealing will increase the risk of pinholing. Very porous substrates may require the application of two or more coats of sealer. Whilst it is difficult to determine whether a substrate has been sufficiently sealed, a sheen on the surface of the substrate is an indication of adequate sealing.

Prime the sealed surface by applying one coat of RonaScreed Self Smooth Primer diluted with 3 parts water at the rate of 0.71 litres/m2. Brush this well into the surface. Apply RonaScreed Self Smoothing Levelling Topping whilst primer is tacky; typically between 2-4 hours after application based on material, ambient and substrate condition of 20°C @ 65%RH.

Notes

- Major imperfections or deviations in the substrate may need to be made good before laying RonaScreed Self Smoothing Levelling Topping

- Allow the sealer to dry

- Always prime surface within 36 hours of sealing operation

- Remove ponded primer

- Always apply RonaScreed Self Smoothing Levelling Topping on to tacky primer

- RonaScreed Self Smoothing Levelling Topping is self smoothing but not self levelling. It must be levelled with a pin rake before spike rolling

- RonaScreed Self Smoothing Levelling Topping is a free flowing liquid consistency screed. It is essential that prior to pouring, adequate precautions are taken to ensure that the material is retained

Mixing/Laying

RonaScreed Self Smoothing Levelling Topping may be applied either by mixer/ pump Putzmeister SP 11 THF (or similar, note that continuous feed pumps may not provide adequate dispersal of components) or when mixing smaller quantities, mix with a slow speed drill ≤ 450RPM fitted with an MR3 type helical paddle and pour onto the floor. Pump or pour RonaScreed Self Smoothing Levelling Topping onto the prepared and sealed/primed surface and level with a pin rake. Spike rolling is necessary to expel entrapped air and must be completed before the mix begins to gel, to avoid leaving spike marks in the surface.

For pump applications it is recommended that a contractor with the necessary experience to carry out this type of work is employed.

It is recommended that when applying RonaFloor HB100 or RonaFloor HB200, a coat of RonaFloor EWB water based epoxy coating should be applied to RonaScreed Self Smoothing Levelling Topping as a penetrative primer.

Estimating Guide

- 5mm screed: 8.5kg/m

2

- 10mm screed: 17.0kg/m

2

- 15mm screed: 25.5kg/m

2

- 20mm screed: 34.0kg/m

2

Priming with RonaFloor Epoxy DPM

RonaFloor Epoxy DPM @ 3.3m2/kg: 0.8-1.4mm kiln-dried sharp sand @ 2.5kg / m2

Sealing and Priming with RonaScreed Self Smooth Primer

Divide surface area by 3.5 to calculate quantity of litres of RonaScreed Self Smooth Primer needed for sealing and priming e.g. 1000m2 divided by 3.5 = 286 litres of Primer needed which is enough for one coat of sealer and one coat of primer).

Application Temperature

The substrate and ambient temperature must not be less than 5°C on a rising thermometer at time of application. Materials should be at a temperature of 15°C-20°C at time of application; lower temperatures will impair flow and surface finish. There should be light ventilation during and after laying.

Apply the material within 15 minutes of mixing (at 20°C). Protect the fresh screed from direct sunlight during the hydration/drying process. Low temperatures will reduce the flow of the wet screed and increase the risk of surface undulations and imperfections. Take extra care when working at low temperatures.

Joints

It is recommended that isolation joints are positioned in doorways. Large areas should be sub-divided by using temporary dividing strips to limit bay width, ensuring that a wet edge is maintained. Bay joints and movement joints in the substrate must be brought through into the topping.

Cleaning

Tools and equipment should be cleaned with water immediately after use. Cured material can be removed mechanically or by acid etching.

Data sheet

- Manufacturer

- Ronacrete

- For Use By

- Professional Use

- Interior / Exterior Use

- Interior Use

- For Use On

- Concrete Floors

- Pack Size

- 25KG

- Minimum Applied Thickness

- 5mm

- Maximum Applied Thickness

- 20mm

- Mixing Ratio

- 3.5-3.7 litres of water per 25KG pack

- Tensile Strength

- 4N/mm²

- Flexural Strength (at 20°C)

- 9N/mm² (28 days)

- Max. Application Temperature

- 20°C

- Min. Application Temperature

- 5°C

- Dry for Light Traffic (at 20°C)

- 24 hours

- Compressive Strength

- 30N/mm² (28 days)

- Colour(s)

- Standard Colours

- Working Time

- Up to 30 minutes

- Suitable For Use On

- Concrete Floors

- Manufacturer

- Ronacrete

- Usages

- Heavy Wear Resistance

- Usages

- Quick Drying

- Product Usage Type

- Topping

- Product Range

- RonaScreed

- Foot Traffic

- 24 hours (20°C)

- Dry for Heavy Traffic

- 7 days

- Bond Strength

- 1.3N/mm²

- Colour Family

- Grey

- Shrinkage

- 0.02% linear (28 days)

- Flow

- 190mm ±15mm

At 20°C, using 65mm diameter x 40mm flow ring

Questions

Question about the product

Be the first to ask a question about this product!

IMPORTANT SHIPPING & DELIVERY INFORMATION

Ronacrete RonaScreed Self Smoothing Levelling Topping is only available with the shipping and delivery timescales listed below - please do not contact our Customer Support Team with enquiries about alternative or earlier shipping and delivery times.

Saturdays and Sundays, as well as Bank Holidays, are not classed as working days.

Orders placed after the cut-off for this product will not be processed for earliest dispatch until 9am the next working day.

All delivery costs below are excluding VAT

Ronacrete RonaFloor Epoxy DPM

A two pack solvent free, liquid applied surface damp proof membrane designed to reduce the passage of water vapour. Reduces water and water vapour permeability Can be applied on substrates with a Relative Humidity up to 97% Excellent adhesion to concretes and screeds Reduces project timescale; less time waiting for screed and concrete...

Ronacrete RonaFloor HB100

Solvent-free, two-component epoxy floor coating that provides an economical wear resistant surface on concrete and polymer modified screeds. Ronacrete RonaFloor HB100 is available in a range of colours available for decorative appearance and demarcation of zones Apply to RonaFloor Epoxy DPM on drying concrete BS 8204-6 & FeRFA Class 2...

Ronacrete RonaFloor HB200

A FeRFA Class 3 and BS 8204-6, two-component, solvent-free epoxy floor coating for use on concrete and polymer modified screeds. Ronacrete RonaFloor HB200 provides excellent abrasion and chemical resistance to floors subject to constant traffic, suitable for use in chemical plant storage areas, warehousing, toilets, laboratories and food...

Ronacrete RonaScreed Self Smoothing Levelling Base

Self-smoothing cementitious underlayment screed suitable for application to concrete floors from a minimum 5mm thickness to a maximum 60mm, and for application in wet areas. Self smoothing cementitious floor screed Base layer for RonaScreed Self Smooth Topping or floorings such as vinyl or tiles Suitable for wet areas Up to 1500m2 can be...