- There are no more items in your cart

- Shipping Calculated at checkout

-

Sub-Total (inc. VAT)

£0.00

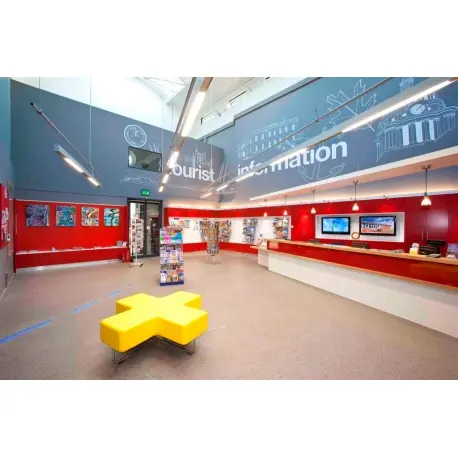

4-part decorative seamless floor finish for public areas such as shopping centres, airports and supermarkets.

- Comprised of inert marble aggregates and epoxy resin to provide both a high wear and decorative finish.

- Chemical resistant.

- Anti-slip.

- Extremely hard wearing.

- Hot water resistant.

- Decorative.

- Formerly known as R.S. Terrazzo and Resustat Terrazzo.

Resuflor Terrazzo (formerly known as R.S. Terrazzo and Resustat Terrazzo) is a heavy duty decorative epoxy terrazzo effect seamless floor finish produced from inert marble aggregates and epoxy resin. Resuflor Terrazzo is ideal where there is both a high wear and aesthetic decorative requirement such as shopping centres, retail outlets, airport terminals and office buildings.

It was installed in Hope Hospital by Balfour Beatty, a commission from Salford Royal NHS Foundation Trust. It was during this project that the marble aggregates were combined with granite aggregates to fit their requirements.

Resuflor Terrazzo was also used to refurbish the floor, stairs and ramped areas of Manchester Central Library, keeping in fitting with the Grade II Listed building’s decor.

Features & Benefits

- Decorative

- High chemical resistance

- Resistant to hot water and steam

- Excellent slip resistant finish

- Extremely hard wearing

- Recommended uses:

- Building entrances

- Food manufacture and processing

- Retail outlets

- Corridors

- Pharmaceutical & chemical plant processing

- Abattoirs

- Heavy duty plant and traffic areas

Product Information

| Product Information | |

|---|---|

| System Thickness (Recommended) | 8-10mm |

| Solids Content by Weight | 100% |

| Pack Make Up | 1 x Base 1 x Hardener 1 x Powder Aggregate 1 x Aggregate |

| Shelf Life | 12 months (Base, Hardener & Aggregates) |

| Storage | Keep out of direct sunlight. Store in a dry place, between 15°C- 30°C |

| Application Information (at 20°C) | |

| Coverage Rate (Theoretical) | 30Kg will cover 1.5 m 2 @ 10mm ground back to 8mm |

| Pot Life | 30 Minutes |

| First Grind | 48-72 hours |

| Wet Polish | 16-24 hours after grouting |

| Final Seal Coats | 16-24 hours after wet polishing |

| Full Chemical Cure | 7 days |

| Technical Information | |

| Category Guide | FerFA Category 8 |

| Slip Resistance | Dry >60 |

| Method BS7976 pt1-3 2002 | Wet - Please consult Sherwin-Williams/Rawlins Paints Technical |

| The slip resistance of a floor surface can vary as a result of the installation process, conditions at the time of application and subsequent traffic. Inappropriate cleaning or maintenance can adversely affect the performance. For further advice on potential wet areas please consult Sherwin-Williams/Rawlins Technical | |

| Abrasion Resistance (Method BS8204 /ASTM D4060) | n/a |

| Temperature Resistance | Tolerant of temperatures up to 120°C at 9mm |

| Chemical Resistance | Good chemical resistance - Consult Sherwin-Williams/Rawlins Technical |

| VOC | < 9 g/l Calculation based on a full mixed unit |

| Life Expectancy | Up to 10 years - subject to industrial traffic. Sherwin-Williams terms and conditions will apply |

Products required for this system

- Primer : Resuseal WB, Resuprime ST on dry substrates, or use Resuprime MVT on damp surfaces where required

- System : Resuflor Terrazzo

- Surface Seal : Resupen WB Clear/Clear Matt

Preparation

New Concrete Floors:

Must be clean, sound, dry, fully cured and surface laitance removed by vacuum enclosed shot blasting, scarifying or mechanical grinding. Fats, oils or greases must be removed by mechanical means and detergent washing and make sure all residue detergent is washed and removed by rinsing with clean water.

Existing Floors (previously coated)

All previous coatings and loose floor paints must be removed by mechanical preparation as described in the above section and primed as specified. If the old resin flooring cannot be removed, then please consult with our technical team for advice on intercoat adhesion and suitability as it may not be compatible with existing floor coating.

Where overcoating other systems such as epoxy coatings or screeds, as part of a specified composite system in the data sheets, please follow the recoat time as stated in the individual data sheets, the coating in each stage should be tack free, but not fully cured. If fully cured then mechanical preparation is required to ensure intercoat adhesion.

Priming

Open and porous substrates may require priming with Resuseal WB, also Resuprime ST may be used as primer on dry substrates only with less than 75% ERH reading. Where the Relative Humidity of a substrate exceeds 75% ERH Resuprime MVT should be specified and selected on the basis of hygrometer readings in accordance with BS 8203.

The number of coats to be applied is chosen in accordance with the following table:

| ERH% | Required Coating Thickness |

|---|---|

| 75-85 | 1 coat of Resuprime MVT at 200 microns per coat |

| 85-92 | 2 coats of Resuprime MVT at 200 microns per coat |

| 92-97 | 3 coats of Resuprime MVT at 200 microns per coat |

Application

The ambient temperatures of the areas should not be allowed to fall below 15°C throughout the application and the curing period, as this could have an adverse effect on the appearance and colour of the system. Surface temperature must be above 10°C. Where possible it is recommended that the application area is heated to a minimum temperature of 15°C ideally to allow the ambient and substrate temperature to stabilize prior to installation.

Mixing:

Pre-mix the coloured base component to a uniform consistency then mix the entire contents of the base with the hardener. If a separate mixing bucket is being used mix thoroughly ensuring all contents of both components are removed from the buckets supplied. Transfer to a forced action mixer and add the aggregate components slowly whilst mixing. Add the powder first followed by the marble aggregate. Mix for approximately two to three minutes until the three components have fully combined.

Resuflor Terrazzo should be worked with a trowel or float to achieve a dense, compacted finish. Apply at nominal 10mm between battens to the primed concrete with a steel float to produce a uniform level finish. This is best achieved by the application of smooth even pressure in one direction, gradually increasing the pressure as the material compacts and beds down.

After curing for a minimum of 48 hours at 20°C, grinding can commence on Resuflor Terrazzo. This is followed by a fine cut to remove cutting marks. Care must be taken to use appropriate equipment to achieve the necessary finish.

Data sheet

- Manufacturer

- RSL

- For Use By

- Industrial Use

- Interior / Exterior Use

- Interior Use

- For Use On

- concrete Floors

Concrete Ramps

Concrete Steps - Application Method

- Trowel

- Parts

- 4

- Base Type

- Water-based polyurethane resin

- Interior/Exterior Use

- Interior

- Minimum Applied Thickness

- 10mm, ground back to 8mm

- Suitable Substrates

- Concrete

- Key Features

- Decorative terrazzo effect, hardwearing and chemical resistant

- Application

- Trowel, Float

- Dry to Recoat (at 20°C)

- -

- Fully Cured (at 20°C)

- 7 days

- Coverage

- 30Kg will cover 1.5 m 2 @ 10mm ground back to 8mm

- Recommended Thinner/Cleaner

- R.S. Industrial Floor Cleaner, R.S. Tyre Mark Remover, R.S. Fats, Oils & Grease Remover & R.S. Oil Remover.

- Compatible Primers

- Resuseal WB, Resuprime ST, Resuprime MVT

- Max. Application Temperature

- -

- Min. Application Temperature

- 15°C

- Density

- 1.04 (relative)

- Solids by Volume

- -

- Dry for Light Traffic (at 20°C)

- -

- Dry for Full Traffic (at 20°C)

- -

- Suitable For Use On

- Concrete

- Suitable For Use On

- Concrete Floors

- Suitable For Use On

- Concrete Ramps

- Suitable For Use On

- Concrete Steps

- Finish

- Anti-Slip

- Application Method

- Trowel

- Components

- 4K

- Product Usage Type

- Coloured Screed

- Product Range

- Resuflor

- Colour Family

- Grey

- Colour Family

- Red

- Colour Family

- Yellow

- Colour Family

- Black

- Colour Family

- White

- Average Application Thickness

- 8-10mm

- Product Type

- Polyurethane

Questions

Question about the product

Be the first to ask a question about this product!

IMPORTANT SHIPPING & DELIVERY INFORMATION

RSL Resuflor Terrazzo is only available with the shipping and delivery timescales listed below - please do not contact our Customer Support Team with enquiries about alternative or earlier shipping and delivery times.

Saturdays and Sundays, as well as Bank Holidays, are not classed as working days.

Orders placed after the cut-off for this product will not be processed for earliest dispatch until 9am the next working day.

All delivery costs below are excluding VAT