- There are no more items in your cart

- Shipping Calculated at checkout

-

Sub-Total (inc. VAT)

£0.00

A 3 component, non-pigmented, solvent-free polyurethane binder designed for car park decks, walkways and driveways, surface dressed with aggregates to create non-slip, hard wearing, textured floor finishes. Can be used in interior or exterior car park decks on a variety of substrates.

- Different aggregates can be used to create various profiles

- High bond strength

- Will cure at temperatures down to 5°c

- Easy and fast to apply

- VOC Free

- Recommended uses include car park decks (intermediate, top and underground), walkways around buildings and factories, theme parks, public pathways and concourse areas, loading bays, demarcation of non-slip areas

Professional use only - from the 24th August 2023, adequate training is required before industrial or professional use of this product.

Should you require training, visit - https://www.safeusediisocyanates.eu/

Professional use only - from the 24th August 2023, adequate training is required before industrial or professional use of this product.

Should you require training, visit - https://www.safeusediisocyanates.eu/

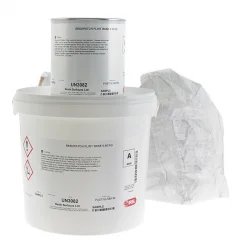

ResuDeck RBS (formerly Resubind CP) is a 3 component, non-pigmented, solvent-free polyurethane binder designed for car park decks, walkways and driveways. Resubind CP is designed for surface dressing with aggregates to create non-slip, hard wearing, textured floor finishes. ResuDeck RBS systems can be used in interior or exterior car park decks on a variety of substrates to provide high wear resistant anti-slip finishes.

Features & Benefits

- Non-pigmented, solvent-free polyurethane binder

- 3 component

- Excellent slip resistant textured finish

- Extremely hard wearing

- Different aggregates can be used to create various profiles

- High bond strength

- Will cure at temperatures down to 5°c

- Easy and fast to apply

- VOC Free

- Recommended uses:

- Intermediate Car Park Decks

- Top Car Park Decks

- Underground Car Park Decks

- Walkways around buildings and factories

- Theme Parks

- Public Pathways

- Public concourse areas

- Loading Bays

- Demarcation of non-slip areas

Product Information

| Product Information | |

|---|---|

| System Thickness (Recommended) | 500—1000 microns (on a sealed and smooth surface) |

| Solids Content by Weight | 100% solids by weight |

| Pack Make Up | 1 x Base 1 x Hardener 1 x 10 Kg Filler SL2 Aggregate |

| Shelf Life | 36 months (Base) 12 months (Hardener) 36 months (Aggregate) |

| Storage | Keep out of direct sunlight. Store in a dry place, between 15°C- 30°C. Aggregates must be stored in a warm, dry place to avoid contamination with moisture which could adversely affect the finish. |

| Application Information (at 20°C) | |

| Coverage Rate (Theoretical) | 19.5 Kg will cover 21 m² at 500 microns thickness or 10.5 m² at 1000 microns thickness. |

| Coverage rate is calculated based on a sealed and smooth surface and may vary based on the substrate roughness and other conditions. | |

| Pot Life | 10-15 Minutes |

| Recoating Intervals | 6-8 hours |

| Light Traffic | 6-8 hours |

| Full Traffic | 16-24 hours |

| Full Chemical Cure | 7 days |

| Technical Information | |

| Category Guide | FerFA Category 4 |

| Slip Resistance | Dry > 60 |

| Method BS7976 pt1-3 2002 | Wet - Please consult Sherwin-Williams/Rawlins Paints Technical |

| The slip resistance of a floor surface can vary as a result of the installation process, conditions at the time of application and subsequent traffic. Inappropriate cleaning or maintenance can adversely affect the performance. For further advice on potential wet areas please consult Sherwin-Williams/Rawlins Technical | |

| Temperature Resistance | Tolerant of temperatures up to 60°C |

| Chemical Resistance | Good Chemical Resistance - Consult Sherwin-Williams/Rawlins Technical on specific materials |

| VOC | <5 g/l Calculated per full mixed unit |

Products required for this system

- Primer : Resuprime PU

- System : ResuDeck RBS

Preparation

New Concrete Floors:

New concrete must be clean, sound, dry, fully cured and surface laitance removed by vacuum enclosed shot blasting or mechanical grinding, a minimum strength of 25N/mm² is required.

Existing Concrete Floors:

Remove all dirt, oil, grease, old paint or any other surface contaminants by vacuum enclosed shot blasting, scarifying or mechanical grinding. Fats, oils or greases must be removed by mechanical means and detergent washing and make sure all residue of detergent is washed and removed by rinsing with clean water. Local repairs should be carried out using Resuscreed PA.

Existing Floors ( previously coated )

All previous coatings and loose floor paints must be removed by mechanical preparation as described in the above section and primed as specified. if the old resin flooring cannot be removed, then please consult with our technical team for advice on intercoat adhesion and suitability, as it may not be compatible with existing floor coating.

Priming

Open and porous substrates will require priming with Resuprime PU, on dry substrates only with less than 75% ERH reading.

Where the Relative Humidity of a substrate exceeds 75% ERH Resuprime MVT should be specified and selected on the basis of hygrometer readings in accordance with BS 8203. The number of coats to be applied is chosen in accordance with the following table.

| ERH% | Required Coating Thickness |

|---|---|

| 75-85 | 1 coat of Resuprime MVT at 200 microns per coat |

| 85-92 | 2 coats of Resuprime MVT at 200 microns per coat |

| 92-97 | 3 coats of Resuprime MVT at 200 microns per coat |

For further information please refer to individual product data sheets.

Application

The ambient temperatures of the areas should not be allowed to fall below 10°C throughout the application and the curing period, as this could have an adverse effect on the appearance and colour of the system. Surface temperature must be above 5°C. Where possible it is recommended that the application area is heated to a minimum temperature of 15°C ideally to allow the ambient and substrate temperature to stabilise prior to installation.

Pre-mix the base component to a uniform colour, then mix the entire contents of base with the hardener. If a separate mixing bucket is being used, ensure all contents of both components are removed from the buckets supplied. Mix using a slow speed electric mixer for approximately one to two minutes until the two components have fully combined then add the aggregate slowly. Mix for a further 1-2 minutes until the aggregate has fully combined and there are no lumps.

The mixed unit should be applied immediately with a squeegee or pin rake. This is best achieved by the application of smooth even pressure with the compound poured over the correct coverage rate after fixing the stop ends to control the flow of the material. Then roll the area with a spiked roller to achieve an even smooth surface and remove entrapped air. Do not re-roll the area later than 10 mins after application. The surface should then be dressed with the selected aggregate at a rate of approximately 2-3 Kg/m².

The surface should be protected from temperatures of less than 5°C and moisture in the early stages of cure. This could adversely affect the flow, levelling and surface finish of ResuDeck RBS.

Data sheet

- Manufacturer

- RSL

- For Use By

- Industrial Use

- Interior / Exterior Use

- Interior & Exterior

- For Use On

- Car park decks

Walkways

Driveways - Application Method

- Squeegee

Pin Rake

Trowel - Colour

- Clear

- VOC Levels

- Ultra-Low (5-49 g/l)

- Single, Two or Three Pack

- Three-Pack

- Pack Size

- 19.5KG

- Minimum Applied Thickness

- 500—1000 microns (on a sealed and smooth surface)

- Solvent

- Polyurethane

- Key Features

- Surface dressing with aggregates to create non-slip, hard wearing, textured floor finishes

- Application

- Squeegee, Pin Rake

- Fully Cured (at 20°C)

- 7 days

- Pot Life (at 20°C)

- 10-15 Minutes

- Coverage

- 19.5 Kg will cover 21 m² at 500 microns thickness or 10.5 m² at 1000 microns thickness

- Unit Contents

- Base, hardener & aggregate

- Compatible Primers

- Resuprime PU

- Compatible Topcoats

- ResuDeck RBS

- Max. Application Temperature

- -

- Min. Application Temperature

- 15°C

- Heat Resistance (up-to)

- 60°C

- Dry for Light Traffic (at 20°C)

- 6-8 hours

- Dry for Full Traffic (at 20°C)

- 16-24 hours

- Base Type

- Solvent Free Polyurethane

- Suitable For Use On

- Underground Car Parks

- Suitable For Use On

- Car Park Decks

- Suitable For Use On

- Intermidiate Car Parks

- Suitable For Use On

- Top Car Parks

- Suitable For Use On

- Floors

- Suitable For Use On

- Concrete Loading Bays

- Suitable For Use On

- Concrete Floors

- Suitable For Use On

- New Concrete Floors

- Suitable For Use On

- Loading Bays

- Suitable For Use On

- Driveways

- Suitable For Use On

- Existing Concrete Floors

- Suitable For Use On

- Carparks

- Suitable For Use On

- Walkways

- Suitable For Use On

- Indoor Car Parks

- Suitable For Use On

- Pathways

- Suitable For Use On

- Concrete Walkways

- Suitable For Use On

- Demarcation

- Suitable For Use On

- Concourses

- Suitable For Use On

- Theme Parks

- Suitable For Use On

- Car Parks

- Application Method

- Trowel

- Application Method

- Squeegee

- Application Method

- Rake

- Components

- 3K

- Product Usage Type

- Binder

- Product Range

- ResuDeck

- Colour Family

- Neutral

Questions

Question about the product

Be the first to ask a question about this product!

IMPORTANT SHIPPING & DELIVERY INFORMATION

RSL ResuDeck RBS is only available with the shipping and delivery timescales listed below - please do not contact our Customer Support Team with enquiries about alternative or earlier shipping and delivery times.

Saturdays and Sundays, as well as Bank Holidays, are not classed as working days.

Orders placed after the cut-off for this product will not be processed for earliest dispatch until 9am the next working day.

All delivery costs below are excluding VAT

RSL Resuprime MVT

A faster curing version of R.S. Dampshield, with overcoat times of 6 hours. A two-component epoxy resin primer, it enables even earlier access onto new or existing concrete substrates for screed and coating applications on carpets, tiles, vinyl and wood. Easy application Use on substrates with hygrometer readings <97% Solvent-free...

RSL Resuflor Patch

RSL Resuflor Patch (Formerly known as Resuscreed PA and Resupatch) is a three-pack epoxy resin mortar designed for rapid concrete repair in heavy duty environments. Excellent mechanical properties Can be feather edged Abrasion and impact resistant Dust-free Concrete like in appearance Easy to apply Minimum surface preparation...

RSL Resuprime PU

We no longer stock this product; please contact our technical team on 0113 2455450 (option 2) or send a message to [email protected] where we will be happy to find an alternative product.