- There are no more items in your cart

- Shipping Calculated at checkout

-

Sub-Total (inc. VAT)

£0.00

Pultruded carbon fibre plate used for repairing and strengthening reinforced cement elements damaged by physical and mechanical stresses, strengthening concrete and wooden members to withstand flexural loads and for the seismic upgrading of structures in high- risk areas.

- Repairs and static upgrading on reinforced concrete beams, floor joists and floor slabs to increase the bending moment

- Flexural strengthening of wooden beams and joists; Repair of structures damaged by fire and by earthquakes

- Renovating two-dimensional structures such as plates, sheets, and storage tanks with a large bending radius

- Reinforce viaduct slabs after an increase of static and/or dynamic loads

- Reinforce industrial and/or commercial structures as a consequence of an increase of static loads brought on by equipment, machinery, etc

- Reinforce car park decks in residential and industrial buildings; Reinforce structures subject to vibration

- Strengthening load-bearing members in buildings whose structural system has been modified due to new architectural requirements or change in use

- For professional use only

Mapei Carboplate E - Pultruded carbon fibre plate with a double plastic protective film.

Quick Links - Click To Jump To Section:

- Features & Benefits

- Technical Characteristics

- Application

- Precautions To Be Taken During Preparation And Application

- Cleaning

- Safety Instructions For Preparation And Installation

- Consumption

- Technical Data

Features & Benefits

- Unlike work based on conventional methods, the Carboplate range of products, due to their extreme light weight, can be used without the need of special machinery or equipment and in a very short time, often without downtime of the structure.

- Unlike the plating method using metal plates (béton plaqué method), Carboplate does not need temporary reinforcements during placing and removes all risks of corrosion of the applied reinforcement.

- Unlike the plating method using impregnated fabric on the job site, Carboplate can be applied quickly and the full success of the operation depends less on the operator’s ability.

- Because of its degree of flexibility, Carboplate can be used to line cylindrical structures (basins, storage bins, holding tanks, etc.) with a bending radius greater than 3m.

Technical Characteristics

Carboplate is a range of pultruded carbon fibre plates, with high resistance and flexibility, for plating prestressed reinforced concrete and steel and wood structures.

Carboplate can replace conventional steel sheets that are used for plating.

Carboplate is available in different widths (50, 100mm) and with three modules of elasticity (150, 170 GPa).

Because of its composition and manufacturing procedure, which ensures constant properties to all parts of the material, Carboplate has the following properties:

- High tensile strength

- Light weight

- Reduced thickness

- Excellent endurance strength

Application

Recommendations

Before bonding, make sure that the concrete substrate has a tensile strength > 1.5 MPa.

Do not use Carboplate on un-cured concrete.

On particularly porous surfaces or on concrete placed in environments with a high R.H. (underpasses, basements, etc.), apply MapeWrap Primer 1 to prime these surfaces before bonding Carboplate (refer to the relevant technical data sheet for the preparation and application of the product). The following application of epoxy adhesives MapeWrap 11 or MapeWrap 12 or Adesilex PG1 must be carried out while MapeWrap Primer 1 is still “fresh”.

Preparation of the concrete substrate

The surface on which Carboplate has to be bonded must be perfectly clean, dry, mechanically strong and smooth (the roughness must not be higher than 1 mm). All traces of form-release agents, varnishes, paints and cement laitance must be removed from the substrate by sandblasting.

If the concrete has deteriorated in depth, remove the damaged parts manually or mechanically or by hydro-scarifying pneumatic bush hammering.

Remove all traces of rust from metal reinforcement rods and protect with Mapefer, a two-component corrosion- inhibiting cement mortar or Mapefer 1K, one-component, corrosion-inhibiting cement mortar (follow application methods described in the relevant technical data sheet).

Repair the concrete surfaces with products from the Mapegrout range.

Wait at least three weeks before applying Carboplate.

If reinforcement must be carried out immediately, use epoxy mortars such as Adesilex PG1 to repair the deteriorated concrete.

Products to use for bonding

In temperatures between +5°C and +20°C, use MapeWrap 11 or Adesilex PG1.

MapeWrap 12 should be used in temperatures higher than +20°C because of the longer pot life.

Preparing MapeWrap 11 or MapeWrap 12 or Adesilex PG1

Mix together the two components that make up MapeWrap 11 or MapeWrap 12 or Adesilex PG1. Pour component B into component A and mix with a drill fitted with a stirrer until the mix is perfectly smooth and even (the same colour grey throughout).

Each component is supplied in pre-dosed quantities. Do not use partial quantities otherwise mixing errors may occur and the system may not harden correctly.

Bonding Carboplate

- Carboplate is supplied in rolls that must be cut on site according to the desired length with an electric saw fitted with a diamond blade

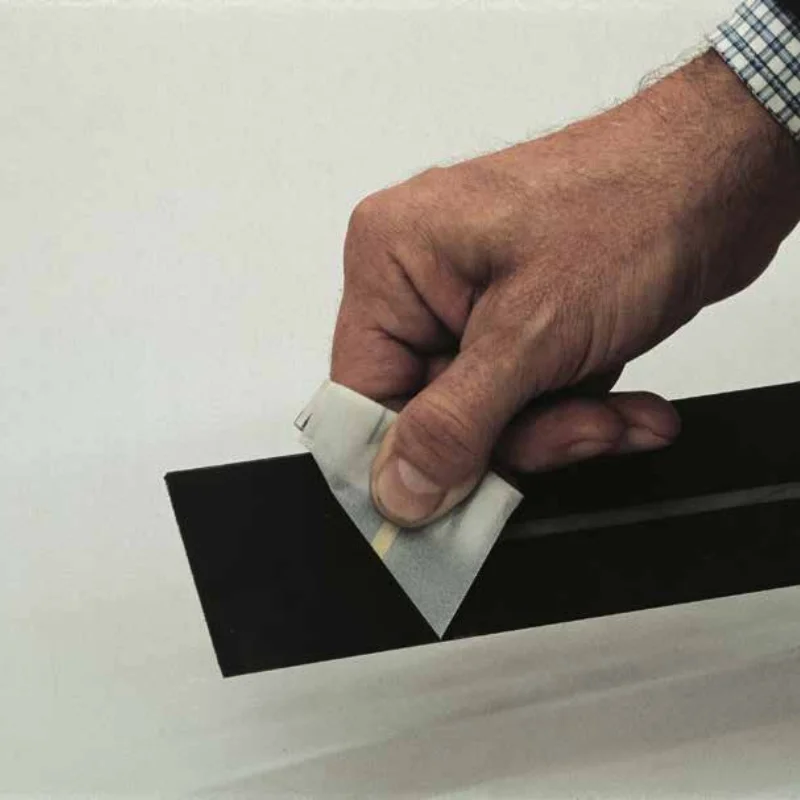

- Furthermore, during its manufacturing, the sides of Carboplate are protected by a plastic sheet. This material protects the plate from dirt while cutting

- Before bonding, this sheet must be removed from Carboplate, that will be placed in contact with the chosen epoxy adhesive

- Prime the surface that needs to be reinforced with MapeWrap Primer 1 (particularly porous surfaces or on concrete placed in environments with a high R.H.)

- Apply a uniform 1-1.5 mm thick layer of Adesilex PG1 (in relation to the temperature) with a flat trowel over Carboplate on the side where the protective sheet has been removed

- Apply a layer of MapeWrap 11 or MapeWrap 12 or Adesilex PG1 also on the substrate (that must be clean and dry) that will receive the plate. The application of the adhesive layer must be carried out while MapeWrap Primer 1 is still “fresh”

- Install Carboplate applying a constant pressure over the whole surface. Use a stiff rubber roller and remove the excess resin with a trowel paying attention not to move the plate

- For plating curved structures, it is necessary to use clamps or supports to hold the plates in place until the resin has completely hardened (usually 24 hours before removing the temporary supports)

- If more layers of Carboplate are necessary, remove the second plastic film from the already installed plate once MapeWrap 11 or MapeWrap 12 or Adesilex PG1 has set, before installing the next plate

The surface plated with Carboplate can be protected with Mapelastic, Elastocolor or with a fire resistant paint.

The protection coat can be applied 24 hours after the installation of the plates.

Precautions To Be Taken Before Preparation And Application

During application the temperature must not be below +5°C and the structure must be protected from rain and dust brought by wind.

Maintain the treated surfaces at a temperature higher than +5°C after work has been carried.

Protect the surface from rain for at least 24 hours. If the minimum temperature does not go below +15°C, or for at least 3 days if the temperature should be lower.

Cleaning

Due to the high bonding strength of MapeWrap 11 or MapeWrap 12 or Adesilex PG1 on metal, it is recommended to clean tools with solvents (ethyl alcohol, toluene etc.) before the product dries.

Safety Instructions For Preparation And Installation

It is absolutely essential that users wear waterproof rubber gloves, protective goggles and clothing while preparing and installing the carbo-plate and epoxy systems (MapeWrap 11 or MapeWrap 12 or Adesilex PG1.

Avoid contact with the eyes and skin.

In case of contact with the skin, wash with water and soap. If the product comes in contact with the eyes, wash with plenty of water and sek medical attention.

When the product is applied in a closed environment, provide good ventilation. For further information carefully read the safety data sheets of the products.

Consumption

The consumption of MapeWrap 11 or MapeWrap 12 or Adesilex PG1 depends on the width of the Carboplate plates; approximately following:

- 50 mm plate: 160-200 g/m

- 100 mm plate: 320-400 g/m

Technical Data

Data sheet

- Manufacturer

- Mapei

- For Use By

- Professional Use

- For Use On

- Wood

- For Use On

- Concrete

- For Use On

- Masonry

- Coverage

- Consumption of adhesive depends on the width of the Carbonplate used, approx:

50 mm plate: 160-200 g/m

100 mm plate: 320-400 g/m; - Max. Application Temperature

- 30°C

- Min. Application Temperature

- 5°C

- Density

- E170: 1.61

- Suitable For Use On

- Masonry

- Suitable For Use On

- Concrete

- Suitable For Use On

- Wood

- Manufacturer

- Mapei

- Product Usage Type

- Reinforcement

- Colour Family

- Black

Questions

Question about the product

Be the first to ask a question about this product!

IMPORTANT SHIPPING & DELIVERY INFORMATION

Mapei Carboplate E is only available with the shipping and delivery timescales listed below - please do not contact our Customer Support Team with enquiries about alternative or earlier shipping and delivery times.

Saturdays and Sundays, as well as Bank Holidays, are not classed as working days.

Orders placed after the cut-off for this product will not be processed for earliest dispatch until 9am the next working day.

All delivery costs below are excluding VAT