- There are no more items in your cart

- Shipping Calculated at checkout

-

Sub-Total (inc. VAT)

£0.00

Need Help?

Structural Repairs and Strengthening

Structural repair is always essential when ensuring the safety of your building, bridge or other structure. We have repair materials to seal connection joints in concrete and masonry, solvent-free and odourless options, age-resistant and anti-weathering, as well as those that can be used on metal. In the case of structural repair, you should ALWAYS talk to a structural engineer before choosing a product or embarking on a project. Our team can help you choose the right materials over the phone, via email, or social media, but we cannot diagnose the extent of your damage. Click here for more info.

Sikadur 30

Sikadur 30 is a thixotropic, structural two part adhesive, based on a combination of epoxy resins and special filler, designed for use at normal temperatures between +8°C and +35°C for bonding Carbon Fibre & Steel reinforcement. Features and Benefits Easy to mix and apply No primer needed High creep resistance under permanent load...

Sikadur 330

Sikadur 330 is a two part, thixotropic epoxy based impregnating resin / adhesive. Used as impregnation resin for SikaWrap fabric reinforcement for the dry application method, primer resin for the wet application system and structural adhesive for bonding Sika CarboDur plates into slits. Features and Benefits Easy mix and application by...

Mapei Adesilex PG1 Rapido

Two-component, ultra rapid-setting thixotropic epoxy adhesive for repairs, bonding and structural strengthening of concrete, reinforced concrete, natural stone, mortar and brickwork structures. Structural strengthening of beams and pillars by bonding steel plates (béton-plaqué technique) or composite material (such as Carboplate) to...

Mapei Adesilex PG1

Structural repair, bonding and reinforcement of concrete elements, natural stone, mortar and brick with very low emissions of volatile organic compounds (EMICODE EC1 Plus). Structural reinforcement of beams and pillars by bonding steel (béton plaqué method) or composite material (e.g. Carboplate) plates to concrete Non-flexible structural...

Sikadur-53

A two-part epoxy crack injection and grouting resin with excellent moisture resistance, ideal for wet and underwater applications. For Professional Use Only Prevents ingress of water and infiltration of corrosion promoting substances Applicable from +5°C to +30°C

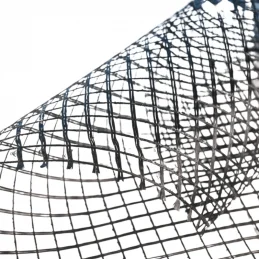

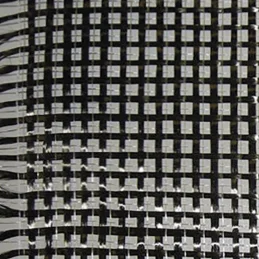

SikaWrap 930 G

SikaWrap 930 G is a woven unidirectional glass fibre fabric, designed for structural strengthening applications as part of the Sika strengthening system. Designed for installation using the wet application process and is used for structural strengthening of reinforced concrete, masonry, brickwork and timber elements or structures, to increase...

SikaWrap 231 C

SikaWrap 231 C is a unidirectional woven carbon fibre fabric with high strength, designed for structural strengthening applications as part of the Sika strengthening system. Installed using the dry or wet application process. Features and Benefits Manufactured with weft fibres to keep the fabric stable (heat-set) Multifunctional fabric...

Sikadur 300

Sikadur 300 is a two part, epoxy based impregnating resin for SikaWrap fabric reinforcement for the wet application method and primer resin for the wet application system. Features and Benefits Easy mix and application by trowel and impregnation roller Manufactured for manual or mechanical saturation methods Good adhesion to many...

Mapei Mapenet EM40

Pre-impregnated alkali-resistant A.R. glass fibre mesh (FRP) used to make “reinforced” structural render on concrete and masonry structures. Some application examples: "Reinforced" render on concrete walls and bay walls Increasing the compressive strength of bay walls Strengthening vaulted roofs by "reinforced capping" Systems to prevent...

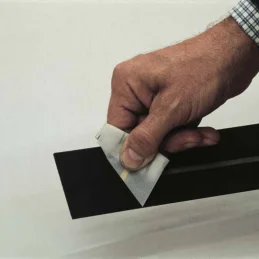

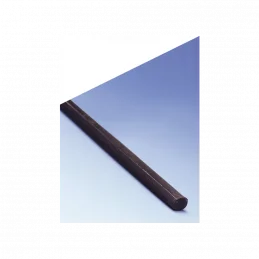

Sika CarboDur M Type

Sika CarboDur M Type plates are pultruded carbon fibre reinforced polymer (CFRP) laminates designed for strengthening concrete, timber and masonry structures. They are bonded onto the structure as externally bonded reinforcement using Sikadur 30 structural adhesive. Features and Benefits Non corrosive Very high strength Excellent...

SikaWrap 301 C

SikaWrap 301 C is a woven unidirectional carbon fibre fabric, designed for structural strengthening applications as part of the Sika strengthening system. Installed using the dry or wet application process. Structural strengthening of reinforced concrete, masonry, brickwork and timber elements or structures, to increase flexural and shear...

SikaWrap 900 C

SikaWrap 900 C is a stitched, unidirectional carbon fibre fabric, designed for structural strengthening applications as part of the Sika strengthening system. It is a unidirectional, fleece stabilised stitched heavy carbon fibre fabric with mid-range strengths, designed for installation using the wet application process. Features &...

SikaWrap FX-50C

SikaWrap FX-50C is carbon fibre cord for the structural connection and anchoring of SikaWrap strengthening systems. It is a unidirectional carbon fibre cord, encased in a plastic sleeve, that serves as a fibre connector for the anchorage of SikaWrap fabrics. Features and Benefits Carbon fibre, corrosion resistant, durable...

Sika FloorJoint S

Sika FloorJoint S is a prefabricated, carbon-fibre reinforced polymer composite panel with high physical properties. Because of the waved joint design an improved load distribution is achieved. Ideal for new build and refurbishment of joints for concrete screeds with normal up to medium heavy wear e.g. for storage and assembly halls,...

Sika CarboDur E Type

Sika CarboDur E plates are pultruded carbon fibre reinforced polymer (CFRP) laminates, designed for strengthening concrete, timber, masonry, steel and fibre reinforced polymer structures. They are bonded onto the structure as externally bonded reinforcement using Sikadur 30 adhesive. Refer to the relevant Product Data Sheet for more detailed...

Mapei Carboplate E

Pultruded carbon fibre plate used for repairing and strengthening reinforced cement elements damaged by physical and mechanical stresses, strengthening concrete and wooden members to withstand flexural loads and for the seismic upgrading of structures in high- risk areas. Repairs and static upgrading on reinforced concrete beams, floor...

Mapei Maperod C

Repairs and structural strengthening for reinforced concrete, brickwork, stone, wooden and tuff elements damaged by physical-mechanical stress or natural causes. Used in combination with fabrics from the MapeWrap range to improve anchorage, especially when interventions are carried out to increase flexural and shear strength (for concrete,...

Mapei Mapewrap 11 & 12

Thixotropic epoxy putties for levelling concrete surfaces, for structural bonding, reinforced concrete or masonry surfaces before applying MapeWrap fabrics. The two products differ from each other only for the workability time: MapeWrap 11 is suitable for applications at temperatures between 5°C and 23°C, while MapeWrap 12 is recommended in...

Mapei Mapewrap 31

Medium viscosity epoxy resin for used for the impregnation of MapeWrap fabrics, when concrete, reinforced concrete and masonry elements need repair or strengthening by using the “dry system”. For professional use only More Information Delivery Info

Mapei MapeWrap C UNI-AX 300

Structural strengthening System consisting of high-strength high-modulus unidirectional carbon fibre fabric and epoxy resins to impregnate and bond the fabric (FRP). Repairs and static and seismic upgrading of unstable or weak structures where the shear and tensile strength need to be supplemented Confining compressed and pre-stressed...

Mapei Planitop HDM Maxi

Two-component ready-mixed high ductility pozzolan-reaction fibre-reinforced mortar for structural “reinforced” reinforcement when used in combination with mesh from the Mapegrid range and for smoothing and levelling concrete and masonry. Application examples include: Cladding facing walls, vaulted ceilings and masonry in general after...

Mapei Planitop HPC

Two-component ultra high performance shrinkage-compensated free-flowing high ductility fibre-reinforced cementitious mortar with stiff steel fibres. For repairing and strengthening of concrete structures that require the use of a free-flowing, ultra-high performance and high ductility mortar without using reinforcing steel in order to limit...

Mapei Planigrout 300

Three-component fluid epoxy mortar for anchorage work. Specifically developed for fixing structural elements, structural repairs and structural fillings which are also subject to stress due to dynamic loads. Application examples include: Repair and structural reinforcement of beams and columns by casting into formworks Rebuilding and...

Mapei MapeWrap C Fiocco

Unidirectional high strength carbon fibre, glass fibre or basalt fibre cord for impregnation with MapeWrap 21 to make “structural connections”. For structural and functional restoration of concrete elements and masonry, including those of historical interest, which have been damaged by inclement weather and natural causes. Application examples...

Mapei Mapegrid B 250 Mesh

Primed alkali-resistant basalt fibre mesh (6 x 6 mm) for structural “reinforced” strengthening of stone, brick and tuff masonry structures. Application examples include: Shear/tensile strengthening of bay walls through application to the internal and/or external face Structural strengthening of masonry arches and vaulted roofs through...

Mapei Mapegrid G 220 Mesh

Primed alkali-resistant A.R. glass fibre mesh (21 x 21mm) for structural “reinforced” strengthening of stone, brick, tuff and mixed masonry structures. Application examples include: Shear/tensile strengthening of bay walls through application to the internal and/or external face Structural strengthening of masonry arches and vaulted roofs...

Mapei Mapegrid C 170 Mesh

High-strength carbon fibre mesh (10 x 10mm) for “reinforced” structural strengthening of masonry and concrete structures. Application examples include: Shear/tensile strengthening of bay walls through application to the internal and/or external face Structural strengthening of masonry arches and vaulted roofs through application to both...

Mapei Steel Dry 316

Ultra high-strength “dry-applied” helical AISI 316 stainless steel bars recommended for structural strengthening of members made from stone, brick and tuff masonry, concrete or wood, to connect masonry panels and wooden floor joists to bay walls and to limit cracking and reinforced stitching of cracked or damaged masonry. Application examples...

Mapei Planitop HDM Restauro

Two-component, pre-blended, fibre- reinforced, high-ductility hydraulic lime (NHL) and Eco- Pozzolan based light-coloured mortar, particularly recommended for “reinforced” structural strengthening of masonry substrates in combination with Mapegrid G 120, Mapegrid G 220 or Mapegrid B 250 and for evening out, stone, brickwork and tuff surfaces....

Mapei Planitop HPC Floor

Fibre-reinforced, shrinkage-compensated, high-strength, high-ductility, highly-fluid cementitious mortar. For repairing and strengthening of reinforced concrete and horizontal structures where high-performance, free-flowing mortar is required to integrate thick layers or fill complex areas. It is particularly suitable for strengthening the...

Mapei Planitop HPC Floor 46

Ultra high-performance high ductility free-flowing micro-concrete reinforced with metal fibres, for repairing and strengthening horizontal structures where high-performance, free-flowing mortar is required to integrate thick layers or fill complex areas. Application examples include: Seismic upgrading of elements exposed to high stresses...

Sika Sikadur-42+ HE Cold Climate

High-performance three-part epoxy grout for cold climates. May only be used by experienced professionals Develops high early strength Suitable for many static or dynamic precision grouting applications Layer thickness of 10mm to 100mm and an application temperature range of 5°C to 30°C Used for high-strength grouting and fixing For...

Need Help?

Need Help?

Structural repairs are a fundamental aspect of ensuring the longevity, safety, and stability of buildings, infrastructure, and essential facilities. Over time, structures face various forms of damage due to environmental exposure, excessive loading, material fatigue, or even errors made during construction. Structural repair products and techniques aim to address these issues, restoring a structure’s integrity and preventing further deterioration. Modern repair technologies, from crack injection systems to carbon fibre reinforcement, provide advanced solutions that allow structures to remain safe and functional for decades to come.

Common Causes of Structural Damage

Understanding how structural damage occurs helps professionals select the right repair approach and materials. Several key factors can compromise the structural integrity of concrete, steel, and other construction materials. The following are the most common causes of structural damage:

- Dormant and Non-Dormant Cracks: Dormant cracks, often hairline in appearance, are typically static and may not worsen over time unless influenced by environmental factors like moisture ingress. For example, hairline cracks in a residential concrete foundation may remain dormant for years but can still serve as entry points for moisture. Non-dormant cracks, however, are dynamic and prone to movement. These cracks occur in environments where the structure experiences ongoing stress, such as industrial floors subject to heavy equipment vibrations, or in bridges affected by continuous thermal expansion and contraction.

Example Repair Solution: Dormant cracks can be repaired using rigid epoxy crack fillers or mortars that restore surface strength. Non-dormant cracks require flexible crack repair systems like polyurethane injection, which allows for movement while keeping the cracks sealed. - Excessive Loading: Structures that experience loading beyond their original design capacity are at risk of severe damage. This occurs in many older buildings that have been repurposed, such as warehouses converted into offices or retail spaces. Over time, the increased weight from furniture, equipment, or additional floors can stress supporting columns, beams, and foundations, leading to cracks or structural deformation.

Example Repair Solution: Carbon fibre-reinforced polymer (CFRP) wraps or steel plate bonding systems can be used to strengthen the load-bearing capacity of columns and beams. For foundations under excessive stress, underpinning systems can reinforce or stabilise the existing structure. - Thermal Expansion and Contraction: Temperature fluctuations cause materials like concrete and steel to expand when hot and contract when cold. Over time, these cycles lead to the development of cracks, particularly in outdoor structures such as bridges, parking lots, or industrial facilities with large concrete surfaces exposed to the elements. Thermal expansion is a common cause of cracks in roads and pavements.

Example Repair Solution: Expansion joints or flexible sealants are used to accommodate the movement caused by temperature fluctuations, while crack repair systems - such as epoxy or polyurethane injection - are applied to existing cracks. - Faulty Construction or Poor Conditions During Installation: Errors made during the construction phase, including improper curing conditions or incorrect measurements, can lead to structural weaknesses. For instance, concrete that is poured in cold weather may not cure correctly, resulting in reduced strength and the potential for early cracking.

Example Repair Solution: In cases of poor-quality concrete, resurfacing products like polymer-modified repair mortars can restore surface integrity. More severe issues may require removal and replacement of affected sections, ensuring that new concrete is properly cured and bonded to the existing structure. - Corrosion of Steel Reinforcement: Steel embedded in concrete provides tensile strength, but it is vulnerable to corrosion when exposed to moisture, chlorides, or de-icing salts. Corrosion causes the steel to expand, leading to cracking and spalling in the surrounding concrete. This problem is common in coastal structures or bridges exposed to road salts during winter.

Example Repair Solution: Galvanic anodes, cathodic protection systems, or corrosion-resistant coatings can be applied to stop or slow down the corrosion process. Epoxy repair mortars are used to repair spalled concrete and protect the steel from further exposure. - Subgrade Settlement: Buildings and structures built on unstable or improperly compacted soil are prone to settlement. As the soil beneath the structure shifts, cracks form in foundations, walls, and floors. Subgrade settlement is particularly problematic in areas with expansive clay soils, which swell and shrink depending on moisture levels.

Example Repair Solution: Resin injection or micropile systems are commonly used to stabilise foundations and lift settled areas. Crack repair systems can then be applied to repair visible damage caused by settlement. - Excessive Shrinkage During Curing: Concrete naturally shrinks as it cures, but improper mix designs or extreme environmental conditions can cause excessive shrinkage, leading to cracks. This issue often occurs in large slabs, such as those used for warehouse floors or roadways.

Example Repair Solution: Shrinkage-reducing admixtures can be added to new concrete mixes to prevent this problem. For existing shrinkage cracks, flexible repair mortars and crack fillers are used to restore the integrity of the slab. - Tensile Stress Exceeding the Strength of Concrete: Tensile stress refers to the forces that pull on a structure, and when these forces exceed the strength of the material, cracks form. Common sources of tensile stress include wind loads, seismic activity, and vibrations from machinery or nearby traffic.

Example Repair Solution: Post-tensioning techniques, carbon fibre reinforcement, or steel plates can be added to strengthen areas where tensile stress exceeds the concrete's capacity. This ensures that the structure can resist future stresses without additional damage. - Fire and Environmental Damage: Exposure to fire or harsh environmental conditions such as moisture, chemicals, or salt can significantly weaken concrete and steel structures. Fire damage, in particular, compromises the integrity of concrete, reducing its load-bearing capacity.

Example Repair Solution: For fire-damaged concrete, specialised heat-resistant repair mortars are applied to restore surface strength. In areas prone to chemical exposure, chemical-resistant coatings or repair systems are used to protect against future degradation.

Structural Repair Solutions and Techniques

A wide range of structural repair products and techniques exist to address the many causes of damage. These methods vary depending on the severity and type of damage, with advanced solutions providing long-lasting results. Here are some of the most effective structural repair techniques:

- Crack Injection Systems: One of the most effective methods for repairing both dormant and non-dormant cracks is crack injection. Epoxy injection is typically used for structural repairs where strength is required. It bonds cracks and restores the original strength of the concrete. Polyurethane injection is used for non-dormant cracks, as it provides flexibility and accommodates movement.

Example: An industrial warehouse floor subjected to heavy forklift traffic develops non-dormant cracks. Polyurethane injection is applied to the cracks, allowing the floor to withstand ongoing movement without further deterioration. - Carbon Fibre Reinforcement: Carbon fibre-reinforced polymer (CFRP) wraps are a lightweight, high-strength solution for reinforcing beams, columns, and slabs. This technique is often used in retrofitting projects to increase the load-bearing capacity of older structures or in seismic retrofitting to provide additional flexibility and strength.

Example: A high-rise building in an earthquake-prone area is retrofitted with CFRP wraps around its columns and beams to improve its ability to withstand seismic forces. This solution enhances the building's structural resilience without adding significant weight. - Corrosion Control and Prevention: Corrosion of steel reinforcements is a significant concern, particularly in environments exposed to saltwater or de-icing chemicals. Cathodic protection systems, galvanic anodes, and anti-corrosion coatings are used to stop or slow the corrosion process, protecting the steel and extending the lifespan of the structure.

Example: A bridge located in a coastal area is treated with galvanic anodes to protect its steel reinforcements from saltwater corrosion. After applying anti-corrosion treatments, the concrete surrounding the steel is repaired with a corrosion-resistant mortar. - Concrete Resurfacing: Concrete resurfacing is often necessary when the surface layer of a structure has been compromised by wear, weathering, or mechanical damage. Epoxy-based overlays or polymer-modified repair mortars are used to restore the surface's durability while preventing further deterioration.

Example: A concrete pedestrian walkway in an outdoor shopping centre shows signs of wear and cracking due to heavy foot traffic. An epoxy overlay is applied to the surface, restoring its durability and providing a slip-resistant finish for increased safety. - Steel Plate Bonding: When additional tensile strength is needed, steel plates can be bonded to key structural elements. This method is commonly used in industrial settings where machinery or equipment weight exceeds the original design specifications.

Example: A factory floor is repurposed to support heavier production equipment, and steel plates are bonded to the concrete beams and columns to increase their load-bearing capacity. This reinforcement allows the structure to handle the additional weight without extensive reconstruction. - Injection Grouting: Injection grouting involves injecting grout mixtures - typically made from cement or resin - into voids, cracks, or gaps in concrete, masonry, or soil. Grouting helps stabilise and reinforce the structure, making it particularly useful in repairing foundations or filling large cracks.

Example: A multi-storey car park experiences settlement in one of its columns, leading to significant cracks in the concrete. Injection grouting is used to fill the voids and cracks, stabilising the column and preventing further settlement. - Post-Tensioning Techniques: Post-tensioning is a method used to reinforce concrete structures by adding tension to steel tendons within the concrete. This technique helps prevent cracking and enhances the structure’s ability to resist tensile stress.

Example: A large bridge experiencing excessive tensile stress due to wind and traffic loads is retrofitted with post-tensioned steel tendons to prevent cracking and increase its tensile capacity.

Applications Across Market Sectors

Structural repair products are used across various sectors, each presenting unique challenges and requirements. Different industries rely on structural repairs to ensure the safety, functionality, and longevity of their facilities. Below is a detailed exploration of the key sectors where structural repair solutions are essential:

- Construction and Infrastructure: Structural repairs are critical in both new construction and the maintenance of ageing infrastructure. Roads, bridges, tunnels, and public buildings are subject to constant stress from environmental exposure, heavy traffic loads, and natural disasters like earthquakes or floods. Repairs in these environments must meet high safety standards while providing durability and resilience.

Example: A motorway bridge shows signs of spalling and cracking due to freeze-thaw cycles and heavy traffic. The damaged sections of concrete are removed, and the steel reinforcements are treated with corrosion inhibitors. An epoxy-based repair mortar is then used to restore the damaged concrete, and a flexible polyurethane sealant is applied to the cracks to accommodate future movement.

Example: A tunnel used by trains requires structural repairs due to water ingress causing cracks in the concrete walls. Polyurethane injection is applied to seal the cracks and prevent water from entering the tunnel. Carbon fibre wraps are then used to strengthen the tunnel walls, ensuring the structure remains safe for continued use. - Industrial Facilities: Industrial environments are particularly harsh on structures due to the presence of heavy machinery, chemical exposure, and extreme temperatures. Structural repairs in these facilities must be robust enough to withstand continuous stress and the corrosive effects of chemicals or high temperatures.

Example: A chemical plant suffers from concrete degradation in its storage tanks due to constant exposure to corrosive substances. The damaged concrete is repaired using a chemical-resistant repair mortar, and an anti-corrosion coating is applied to protect against future chemical exposure.

Example: An industrial warehouse that supports heavy machinery develops cracks in its foundation due to the constant movement of forklifts and other heavy equipment. Resin injection is used to stabilise the foundation, while flexible polyurethane crack injection repairs the cracks to accommodate ongoing stress. - Heritage and Historic Buildings: Restoring and preserving historic buildings presents unique challenges, as it is essential to maintain the original aesthetic and materials while reinforcing the structure. Heritage buildings often suffer from dormant cracks, subgrade settlement, or damage caused by environmental exposure. Specialist repair techniques are required to preserve the building’s integrity without compromising its historical value.

Example: A 19th-century stone cathedral shows signs of settlement and cracking due to shifting soil beneath its foundation. A combination of micropile underpinning and injection grouting is used to stabilise the foundation. Lime-based repair mortars are applied to repair cracks in the stone masonry, ensuring the repairs blend with the original structure.

Example: A historic brick building develops cracks in its walls due to environmental exposure and ageing mortar. The cracks are repaired using specially formulated repair mortars that match the original brick and mortar colour, preserving the building’s historical appearance. - Residential and Commercial Properties: Residential homes and commercial buildings are not immune to structural damage, especially in areas prone to expansive soils, poor drainage, or seismic activity. Regular structural repairs are necessary to prevent costly damage and ensure the safety of occupants.

Example: A residential home in an area with expansive clay soil develops cracks in its foundation due to seasonal soil movement. The cracks are sealed with a flexible polyurethane injection system, and resin injection is used to stabilise the soil beneath the foundation.

Example: A commercial building in a busy urban area shows signs of cracking due to nearby construction and vibrations from heavy traffic. Carbon fibre reinforcement is applied to strengthen the building’s walls, and epoxy crack injection is used to repair visible cracks. - Marine and Coastal Structures: Coastal and marine structures are constantly exposed to saltwater, which accelerates the corrosion of steel reinforcements and degrades concrete. These structures require regular maintenance and repairs to prevent severe structural damage and extend their lifespan.

Example: A seawall protecting a coastal town from storm surges develops spalling and cracks due to saltwater exposure. The steel reinforcements within the seawall are treated with corrosion inhibitors, and the damaged concrete is repaired using a marine-grade repair mortar designed to resist saltwater exposure.

Example: A concrete pier used for docking ships suffers from corrosion due to constant exposure to saltwater. The pier’s steel reinforcements are protected with galvanic anodes, and a corrosion-resistant overlay is applied to the surface of the concrete to prevent future damage.

For detailed product recommendations and assistance with specific structural repair needs, contact Rawlin’s technical support team. Their expert advice will ensure the correct materials and techniques are applied to your project, helping achieve long-term durability and structural integrity.