- There are no more items in your cart

- Shipping Calculated at checkout

-

Sub-Total (inc. VAT)

£0.00

Need Help?

Thickening Agents

Thickening agents are crucial for enhancing the viscosity of paints and coatings, improving their workability and performance. They ensure a smooth, even application, reducing sagging and improving surface coverage. These agents are key in industries like construction, automotive, and marine, where precise application and durability are required. Selecting the appropriate thickening agent is vital for achieving optimal results on various substrates and in different environmental conditions.

Remmers Add TX New

Single-pack polymer-modified thixotropic agent for epoxy resin and polyurethane systems. Suitable for use in epoxy resin and polyurethane applications where enhanced viscosity control is required. Generates very little dust, making it easy to handle and apply. Simple to portion and mix for controlled, precise application. Adapts to site...

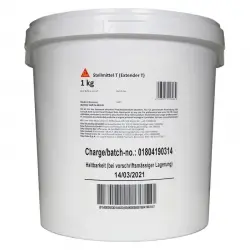

Sika Extender T

Sika Extender T is an inert, fine, white, fibrous polymer powder used as a thickening agent for certain Sika coating systems. It can be used in combination with Sika Epoxy, Polyurethane and MMA systems. Features and Benefits Allows for viscosity adjustment during Sika resin applications to suit site conditions Economical, easy to mix and...

Need Help?

Need Help?

Thickening agents are specialised additives used to modify the viscosity of paints, coatings, and other liquid products. By increasing the thickness, they improve the flow, control sagging, and help the coating adhere more uniformly to the surface. This results in better performance and a more durable finish, especially in professional settings where precision and application quality are critical. These agents can also influence how the coating behaves during application, ensuring consistency across large surface areas.

Thickening agents are commonly used in construction, automotive, and marine industries, where surface coatings must withstand harsh environmental conditions. In construction, they are employed in floor coatings and exterior paints that require enhanced durability and resistance to weathering. In the automotive industry, they help ensure consistent coverage on vehicle bodies, protecting against corrosion. Marine applications benefit from thickening agents in coatings designed to protect surfaces from water and salt damage. The selection of the correct agent is essential for optimising the performance and longevity of the coating, particularly in demanding industrial environments.

Can thickening agents be used with both water-based and solvent-based coatings?

Yes, thickening agents are available for both water-based and solvent-based coatings. However, the compatibility depends on the specific formulation of the coating and the type of thickening agent used. It's important to select an agent that is designed for the particular system to ensure optimal performance.

Do thickening agents impact the drying time of the coating?

Thickening agents can affect the drying time, but the extent varies depending on the agent used. Some may slightly slow down the drying process due to increased viscosity, while others are designed to minimise any impact. It’s advisable to test the product to understand how it interacts with the coating system.

Are thickening agents suitable for high-temperature environments?

Certain thickening agents are formulated to withstand high temperatures, providing stability in extreme conditions. When selecting a thickening agent for high-temperature applications, it's crucial to choose one with thermal stability to maintain the performance and appearance of the coating.

How do thickening agents affect the application of coatings on vertical surfaces?

Thickening agents are particularly useful for coatings on vertical surfaces, as they reduce sagging and running. By increasing the viscosity, they help the coating stay in place during application, resulting in a more even and controlled finish.

What factors should be considered when choosing a thickening agent for a specific substrate?

When selecting a thickening agent, consider factors such as the type of coating (water-based or solvent-based), the application method, the substrate's nature, and the environmental conditions it will face. Compatibility testing is recommended to ensure the agent performs as expected with the chosen coating system.