- There are no more items in your cart

- Shipping Calculated at checkout

-

Sub-Total (inc. VAT)

£0.00

Need Help?

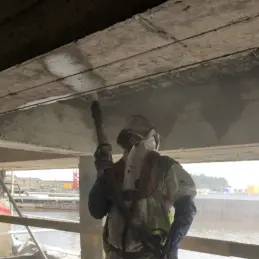

Vertical and Overhead Repairs

Vertical repair products are for use on a selection of materials including masonry, stonework, asphalt, concrete and metal. Walls can easily become damaged, whether it be filling cracks or a decorative repair that you require, we have repair products to fix any blemishes on your edifice. Listed products not only fill cracks or crevices, but components to enhance waterproofing, chemical resistance and prevent abrasion. There are also joint fillers for filling dormant and non-dormant cracks prior to decorating. Click here for more info.

Fosroc Renderoc DS

Fosroc Renderoc DS is a polymer modified, fibre reinforced, low rebound, dry spray repair mortar designed for concrete repairs to buildings, bridges, tunnels and marine structures such as culverts. Suitable for both isolated and large area repairs to beams, columns and panels, and can be used as wide scale overlay system to increase cover...

Sika MonoTop 615

Sika MonoTop 615 is an R3 Classification, One-Component, Cementitious, High Build Concrete Repair and Reprofiling Low Density Mortar, particularly suited to overhead and vertical repairs. Low density for ease of use For repairing all types of structures Hand applied repairs Repairs requiring mechanical (spray) application For exterior...

Sika MonoTop 614F

Sika MonoTop 614F is a cement based, one component flowable repair mortar (High Flow) containing shrinkage compensators and high range water-reducing agents, meeting the requirements of Class R4 of BS EN 1504-3. Ideal for use on horizontal or vertical repairs, bridges, marine structures, tunnels, buildings, etc. For interior and exterior use...

Fosroc Renderoc HB45

Fosroc Renderoc HB45 is a high performance, fibre reinforced, high build, high strength concrete reinstatement mortar, applicable by hand or wet spray, suitable for repair methods 3.1, 3.3, 4.4, 7.1, 7.2 as defined by BS EN 1504-3. Specifically developed for the repair of columns and beams, but because of its medium fresh wet density, is...

Fosroc Renderoc GP

Fosroc Renderoc GP is a general purpose medium density concrete reinstatement mortar specifically engineered for vertical repair work and can also be used as a render coat, and suitable for repair methods 3.1, 3.3, 4.4, 7.1, 7.2 as defined by BS EN 1504-3. Ideal for the reinstatement of concrete where low permeability characteristics are...

Fosroc Renderoc HB

Fosroc Renderoc HB is a high build, polymer modified, cementitious repair mortar. Its lightweight nature and high build characteristics makes it ideal for vertical and overhead repair work, and suitable for repair methods 3.1, 3.3, 4.4, 7.1, 7.2 defined by BS EN 1504-3. Ideal for the reinstatement of concrete where low permeability...

202 Vertical Surface Repair Mortar

202 Vertical Surface Repair Mortar is a solvent-free fast setting epoxy repair mortar for vertical and overhead repairs. It provides a strong, durable, weatherproof repair for concrete, brickwork, stonework and steel substrates. Excellent adhesion to substrate Very good abrasion and impact resistance High build application in vertical and...

Sika Monotop 4012

Sika MonoTop-4012, a cementitious R4 concrete repair mortar containing recycled waste materials for restoration work, structural strengthing, and preserving or restoring passivity. Repairs to all types of reinforced concrete structures and components for: Buildings, civil engineering structures Marine structures, dams Structures...

Sika Monotop 3020

Sika MonoTop-3020 is a 1-part, cementitious polymer modified, low shrinkage surfacing/ finishing mortar. It contains recycled waste materials and can reduce the carbon footprint application activity calculations. Dust reduced - Application up to 5 mm in 1 layer on vertical and horizontal applications High early strengths even at low...

Fosroc Renderoc ST 05

Fosroc Renderoc ST 05 is a polymer modified cementitious material for application to concrete, masonry, brick/blockwork and mild steel that's BS EN 1504-3 Class R4 compliant. Can be applied to floors, walls and ceilings, both indoors and outdoors High performance, multi-purpose cementitious protective coating, fairing and levelling mortar...

Watco Concrex Vertical - Epoxy Resin Repair Mortar

For essential concrete floor repairs during the winter months and cold environments. Ideal for use in freezer or chiller rooms and unheated areas, inside or outside. Damaged concrete pillars, sills, beams, render and stonework steps, worn and holed floors, fitting guide rails, different levels, and spalled expansion joints. Use inside or...

Ronacrete RonaBond HB40

High build concrete repair mortar for vertical and overhead surfaces where ease of application is as important as strength. Conforms to BS EN 1504-3 - high build repairs to 75mm, application from 6mm Pre-packed formulations offer assurance of consistent high performance Use for structural concrete repair, dubbing out - excellent for thick...

Keim Concretal-MR 2.0 (Concrete Repair Mortar)

Keim Concretal-MR 2.0 (Keim Concrete Repair Mortar) is a cementitious repair mortar designed for quick repair work to concrete surfaces. A single component, polymer modified, cement bound mortar, to be mixed with water. Density: Q = 1.3kg/lt Grain size: 0 to 2mm Fresh mortar bulk density: 2.0 kg/dm3 Compressive strength 28d: 55N/mm²...

Fosroc Renderoc HB30

Fosroc Renderoc HB30 is a high performance, fibre reinforced, lightweight concrete reinstatement mortar. Its lightweight nature and high build characteristics makes it ideal for vertical and overhead repair work, and suitable for repair methods 3.1, 3.3, 4.4, 7.1, 7.2 defined by BS EN 1504-3. Ideal for the reinstatement of concrete where low...

Fosroc Renderoc HBS

Fosroc Renderoc HBS is a high performance, fibre reinforced medium build, high strength, concrete reinstatement mortar for the compatible reinstatement of defects in high strength reinforced concrete structures. Particularly suited to the repair of vertical surfaces and, because of its relatively low fresh wet density, can also be used for...

Fosroc Renderoc FC

Fosroc Renderoc FC is a single component polymer modified cementitious fairing coat designed for vertical and overhead use to infill honeycombing and voids up to 3 mm deep in the surface of concrete which is not trafficked and is subsequently coated. Exhibits excellent thermal compatibility with concrete and is fully compatible with other...

Ronacrete RonaBond Concrete Cover Elastic

Coating designed to improve equivalent concrete cover to reinforcement. A 2mm layer provides 150mm equivalent concrete cover providing corrosion protection to steel reinforcement, thus extending the life of the concrete. Protective coating for concrete Elastic, covers fine cracks Waterproof, easy to apply, and touch dry is as little as 30...

Mapei Mapegrout T60

Fibre-reinforced, sulphate-resistant thixotropic mortar for repairing concrete. Repair of degraded concrete structures or reinforced concrete structures subject to sulphate attack. Canal linings, hydraulic works, and tunnels that require resistance to sulphate attack Repair and reconstruction of concrete coverings damaged by corroded...

Keim Concretal-FSP 0.2 (Fine Finishing Mortar)

Keim Concretal-FSP 0.2 (Fine Finishing Mortar) - Fine filler for the KEIM Concretal concrete repair system. Supplied in 25kg Bag Up to 12-months shelf life Apply using trowel or spray One-component – Low-shrink – Crack-free haredening Frost-resistant and salt-resistant Resistant to aging – Synthetic-modified Note: The name of this...

Ronacrete RonaBond FC for Prison Cells

Polymer modified, pre-packed fairing coat. Applied as a skim coat in thicknesses up to 3mm to provide a smooth, hard finish to damaged, blemished and repaired concrete surfaces. Ronacrete RonaBond FC for Prison Cells is used as a levelling mortar prior to the application of protective coatings and paints Can also be used to give a "harder...

Mapei Mapemortar HB R3

A medium strength, high build, shrinkage compensated repair mortar for repairing damaged concrete surfaces in overhead, vertical and horizontal situations, where a medium strength high build mortar is required. Meets EN 1504-3 R3 classification Repair of damaged concrete surfaces, corners of beams, columns and other concrete members...

Ronacrete RonaBond HB25

Pre-packed lightweight concrete repair mortar for repairing concrete on vertical and overhead surfaces where ease of application is as important as high strength. Bonds well to concrete, steel and other building surfaces, offering long term performance and protection to structures. Conforms to BS EN 1504-3 - high build repairs to 75mm,...

Resimac Resichem 571 Concrete Repair LW

Resichem 571 Concrete Repair LW is a light weight three part solvent free epoxy repair mortar designed for use on cementitious surfaces. The light weight nature of the material makes it ideal for repairs to overhead columns, sills and vertical concrete surfaces. Suitable for rebuilding lintels, sills, walls, and ceilings. For professional...

Fosroc Nitomortar HB

Fosroc Nitomortar HB is based on a high performance solvent-free epoxy resin system. The special lightweight filler is specifically designed to give excellent ‘hanging’ properties for vertical and overhead work For the fast and permanent reinstatement of concrete, particularly where resistance to chemicals is required - Equal to the...

Fosroc Renderoc FCR

Fosroc Renderoc FCR is a single component polymer modified, fast setting, cementitious fairing coat designed for vertical and overhead use to infill honeycombing and voids up to 3 mm deep in the surface of concrete which is not trafficked and is subsequently coated. Thixotropic and rapid setting properties, particularly suitable for fast...

Fosroc Renderoc DSR

Fosroc Renderoc DSR is a polymer modified, fibre reinforced, low rebound, rapid setting dry spray repair mortar designed for concrete repairs to buildings, bridges, tunnels and marine structures such as culverts. Complies with class R4 according to BS EN 1504-3 Class R4. Suitable for both isolated and large area repairs to beams, columns...

Mapei Mapegrout Gunite

One component, ready-to-use, multi-purpose, fibre- reinforced, cementitious mortar, applied using either the dry or damp spraying technique. For the repair of concrete, stone and masonry structures. Repair of concrete coverings in road tunnels Covering stone or masonry in tunnels Repair of damaged bridges Repair of hydraulic works such...

Mapei Mapegrout Gunite FSD

Fast setting, single component, low dust, fibre-reinforced cementitious spray mortar for wet and dry application. For the repair of concrete, stone and masonry structures, where low dust emission and low rebound is required. Mapegrout Gunite FSD complies with the Highways England specification for repairs to highway structures. Repair of...

Mapei Mapegrout T40

Medium strength (40 MPa), shrinkage-compensated, fibre-reinforced, thixotropic mortar for repairing concrete. For repair of degraded vertical or horizontal concrete surfaces with mortar possessing medium mechanical performance characteristics. Repair of degraded concrete surfaces, corners of pillars and beams, balconies damaged by rusted...

Mapei Mapelastic Guard

Mapei Mapelastic Guard is a two-component, flexible cementitious mortar for protecting large concrete structures subjected to high stress. Complies with the principles defined in EN 1504-9 (“Products and systems for protecting and repairing concrete structures: definitions, requirements, quality control and conformity assessment. General...

Ronacrete RonaBond HB40 Ultra Rapid

High build concrete repair mortar for vertical and overhead surfaces where ease of application is as important as strength. Rapid set and strength gain - high build repairs to 75mm Low temperature use - waterproof and frost proof Smooth surface finish prior to application of protective/decorative coating Use for structural concrete...

Ronacrete RonaBond Easy Skim FC

Polymer modified, pre-packed fairing coat. Applied as a skim coat in thicknesses up to 3mm to provide a smooth, hard finish to damaged, blemished and repaired concrete surfaces. Conforms to BS EN 1504-2 1mm - 3mm application thickness Fair-faced finish on walls and soffits Covers minor blemishes Apply by trowel Apply prior to...

Flexcrete Monolite

Flexcrete Monolite is a low density, high build, fibre reinforced, polymer modified shrinkage compensated mortar for non-structural repair of concrete, brick or stone. Incorporates the latest cement chemistry, microsilica, fibre and styrene acrylic copolymer technology and is easily overcoated with specialist membranes to provide further...

Need Help?

Need Help?

Repairing vertical and overhead concrete surfaces presents unique challenges that require specialist products, designed specifically to adhere to gravity-defying surfaces while curing quickly and providing long-term durability. These surfaces, including walls, columns, and ceilings, are subject to different forces and environmental conditions than horizontal surfaces. As a result, the materials used for repairs must be specially formulated to avoid slippage, sagging, or dripping during application and to offer robust resistance against environmental factors like moisture, temperature fluctuations, and mechanical stress.

Not sure what you're looking for? Rawlins Technical are on-hand by phone, email, and livechat to take your questions and offer expert recommendations for your project requirements.

Vertical Concrete Repair Products

Vertical concrete repair products are engineered to handle the common problems associated with damage to upright structures, including cracks, spalling, and surface deterioration. The key challenge with vertical surfaces is ensuring the repair material adheres properly without slumping or running down the wall. To address this, these products are often developed with a thicker consistency and enhanced bonding properties.

- Consistency and Sag Resistance: The formulation of vertical concrete repair products typically includes thickeners and additives that prevent sagging during application. This thicker consistency ensures that the material stays in place as it cures, even on vertical surfaces. Without this feature, the repair material could slip or fail to properly bond, leading to an uneven or weak repair.

- Bonding Strength: These products are designed to form a strong bond with the existing concrete substrate. They often include polymer-modified mortars or epoxy components that enhance adhesion, ensuring the repair not only fills cracks but also integrates with the surrounding material for structural strength.

- Types of Damage Addressed: Vertical concrete repair products range from simple patching compounds for minor surface damage to more advanced structural repair systems for deep cracks or areas of spalling. Patching compounds are ideal for shallow cracks and surface-level imperfections, while structural repair systems are used for more serious damage that affects the integrity of the wall.

Overhead Concrete Repair Methods

Overhead concrete repairs, such as those needed for ceilings or soffits, demand even greater care in product selection due to the constant pull of gravity. When working on these surfaces, the repair material must adhere instantly, often requiring fast-setting properties to prevent sagging, dripping, or slumping during application. Additionally, these repairs frequently need to be completed quickly and efficiently, especially in industrial or commercial settings where downtime can be costly.

- Fast-Setting Materials: Overhead concrete repair products are typically fast-setting to ensure they stay in place after application. Materials like fast-curing polymer-modified mortars or epoxy-based systems are commonly used for these jobs. Fast-setting formulations allow the repair to cure before it has the chance to sag or deform, ensuring a smooth, seamless finish.

- Thin Layer Application: Overhead repairs often involve applying materials in thin layers to minimise the risk of slumping. Epoxy-based products are popular in these scenarios because they are easy to spread in thin applications while still offering exceptional strength once cured. Fibre-reinforced mortars may also be used to add tensile strength to the repair without requiring a thick application.

- Common Issues Addressed: Overhead surfaces can suffer from a variety of issues, including spalling, cracking, and delamination. These problems are often exacerbated by water damage or freeze-thaw cycles, which cause the surface material to separate from the structure. Using appropriate overhead repair methods, these surfaces can be restored to their original condition while reinforcing the structure for future use.

Structural & Surface Repair Mortars

For more severe damage, such as large cracks, deep spalling, or structural deficiencies, structural and surface repair mortars are used. These mortars are engineered to bond strongly with the substrate, offering both cosmetic repair and structural reinforcement. In many cases, they are also formulated with additives like corrosion inhibitors, which protect steel reinforcement embedded within the concrete from rust and corrosion. This is particularly important in settings where the concrete is exposed to moisture or salt, such as in parking garages, bridges, or coastal buildings.

- Structural Reinforcement: Structural repair mortars are designed to provide reinforcement for concrete that has suffered from significant cracking or degradation. They bond with the existing concrete to restore its load-bearing capacity, ensuring the structure remains safe and stable. These mortars may include fibres or other additives that enhance tensile strength and durability.

- Corrosion Inhibitors: In structures where steel reinforcement is present, corrosion inhibitors are often added to repair mortars to prevent further damage. When steel reinforcement corrodes, it expands, causing cracks and spalling in the surrounding concrete. Corrosion inhibitors protect the steel from moisture and chemicals, helping to extend the lifespan of the repair.

- Surface Restoration: Surface repair mortars are designed for cosmetic repairs as well as structural fixes. They restore the appearance of the damaged area, blending seamlessly with the surrounding concrete, while also strengthening the surface. These mortars are typically used for larger-scale repairs where surface damage extends beyond simple cracks.

Crack Injection Systems

Crack injection systems are a highly effective method for repairing deep or structural cracks in vertical and overhead surfaces. These systems use high-strength materials, such as epoxy or polyurethane resins, that are injected directly into the crack. As the material expands, it fills the void and bonds with the surrounding concrete, restoring both the appearance and structural integrity of the surface.

- Epoxy vs. Polyurethane Injection: The choice between epoxy and polyurethane depends on the nature of the crack and the desired outcome. Epoxy is typically used for structural repairs, as it forms a strong, rigid bond with the concrete. It is ideal for cracks that affect the structural integrity of load-bearing walls or columns. Polyurethane, on the other hand, is more flexible and is often used for non-structural repairs, such as sealing cracks to prevent water infiltration.

- Sealing and Strengthening: In addition to filling the crack, injection systems seal it from water, air, and other elements that could cause further damage. For cracks in basement walls, for example, crack injection prevents water from seeping through and weakening the foundation. This method not only addresses the immediate damage but also protects against future problems.

- Application Process: Crack injection requires specialised equipment to inject the resin into the crack. The resin is injected under pressure, ensuring it penetrates deeply into the crack and fills it completely. Once the resin has cured, the surface is smooth and sealed, and the structural integrity of the concrete is restored.

Concrete Patch Compounds

Concrete patch compounds are used for smaller repairs, such as filling minor cracks, chips, or surface voids in vertical and overhead surfaces. These compounds are typically ready-to-use, requiring little preparation, and cure quickly, making them ideal for minor repairs where time is a critical factor. They can also be used as a preparatory layer before applying a more protective coating.

- Easy Application: Patch compounds are usually easy to apply with basic tools such as trowels or putty knives. They have a smooth consistency that allows for precise application, making them a good choice for small, localised repairs where the focus is on restoring surface aesthetics rather than structural integrity.

- Quick Curing Time: These compounds are designed to set quickly, often within hours, allowing for rapid repairs. This is especially important for commercial or industrial settings where downtime needs to be minimised. Once cured, the patch is durable enough to withstand regular wear and tear.

- Surface Preparation: Before applying a patch compound, it’s important to properly prepare the surface by cleaning it and removing any loose debris or damaged material. This ensures the patch adheres correctly and provides a long-lasting repair. In some cases, a primer may be applied to improve the bond between the patch and the substrate.

Protective Coatings and Sealers

Once repairs to vertical and overhead concrete surfaces are complete, applying a protective coating or sealer is a crucial final step. These products form a barrier against moisture, chemicals, and environmental wear, extending the life of the repair and reducing the likelihood of future damage.

- Moisture Protection: Concrete is porous and can absorb moisture, which can lead to cracks, spalling, and the corrosion of embedded steel reinforcement. Protective sealers, such as silane or siloxane-based products, penetrate the surface to form a water-resistant barrier that protects the concrete from moisture ingress.

- Chemical Resistance: In industrial environments or areas exposed to harsh chemicals, protective coatings offer resistance to chemicals and other corrosive substances. Epoxy and polyurethane-based coatings are often used in these settings to provide a durable, chemical-resistant surface that stands up to heavy use.

- UV and Weather Protection: For exterior vertical surfaces, UV-resistant coatings protect against the damaging effects of sunlight. These coatings help prevent fading, cracking, and deterioration caused by prolonged exposure to the elements. They also provide a weatherproof barrier that guards against freeze-thaw damage in colder climates.

Protective coatings and sealers not only preserve the appearance of repaired surfaces but also provide an extra layer of defence, helping to prevent the need for further repairs down the line.

Types of Repairs and How They Occur

Different types of damage can affect vertical and overhead surfaces, each requiring specific repair methods and products:

- Cracks: Cracks in vertical and overhead surfaces are among the most common issues. They can occur due to structural settlement, temperature fluctuations, seismic activity, or water infiltration. Vertical cracks in basement walls, for example, can allow water to penetrate, leading to moisture problems and potential structural failure. Repairs for cracks often involve filling the gaps with specialist repair mortars or using crack injection systems to ensure a complete and durable fix.

- Spalling: Spalling refers to the flaking or breaking away of the surface layer of concrete, often caused by moisture infiltration or freeze-thaw cycles. This type of damage can leave the underlying structure exposed to further deterioration. Repairing spalled concrete surfaces typically involves removing the damaged material and applying a repair mortar designed to bond well with the existing structure.

- Delamination: Delamination occurs when layers of material separate, often due to poor adhesion during the original construction or because of moisture infiltration over time. This issue is common in plaster ceilings and can lead to large sections of material peeling away, posing a safety risk. Repairs for delamination often involve re-bonding the layers using specialised adhesives or replacing the affected sections entirely.

- Water Damage: Water damage is a significant concern for vertical and overhead surfaces, particularly in areas like basements and exterior walls. Water infiltration can weaken the structural material, lead to mould growth, and cause unsightly staining. Addressing water damage involves not only repairing the surface but also identifying and eliminating the source of the moisture. Products designed for waterproofing and sealing are often used in conjunction with repair mortars to ensure a long-lasting solution.

- Structural Damage: In some cases, vertical and overhead surfaces may suffer from more severe structural damage, such as cracks in load-bearing walls or columns. This type of damage requires immediate attention and the use of high-strength repair products that can restore the integrity of the structure. Reinforcement may also be necessary, depending on the extent of the damage.

Common Vertical and Overhead Surfaces Needing Repair

Vertical and overhead surfaces in both residential and commercial buildings face different challenges compared to flat surfaces like floors. These wall and ceiling surfaces are found in a variety of locations, such as:

- Basement Walls: Basement walls are often subject to vertical cracks, typically caused by the natural settling of the building or hydrostatic pressure from groundwater. These cracks can range from hairline fractures to significant structural splits, allowing water infiltration and weakening the foundation. Vertical crack repair for basement walls requires products specifically designed for both sealing and reinforcing the structure.

- Exterior Building Facades: Exposure to harsh weather conditions, such as freeze-thaw cycles and heavy rainfall, can lead to damage on exterior walls. Over time, vertical concrete surfaces may crack, spall, or become weakened. These issues can compromise the entire building envelope, making vertical concrete repair products essential for maintaining the building's integrity.

- Load-Bearing Columns and Structural Walls: Vertical load-bearing elements such as columns, beams, and retaining walls are critical for supporting the weight of the structure above them. When these surfaces develop cracks or experience spalling, it’s important to address the damage promptly using specialist structural and surface repair products. Even minor damage can weaken these structural elements over time.

- Ceilings and Overhead Surfaces: Overhead surfaces like ceilings are particularly vulnerable to damage and staining from water leaks, vibrations, or the natural settling of the building. Cracking, sagging, and spalling are common issues. Overhead concrete repair methods and products must account for the unique challenge of gravity, requiring materials that bond quickly and hold their shape during application.

- Parking Structures and Bridges: These structures often have both vertical and overhead concrete surfaces that face constant stress from traffic, temperature changes, and moisture. Cracks and spalling in these areas require immediate attention to prevent further damage that could affect the structure’s safety and longevity.

FAQs

- What type of repair products are best for deep vertical cracks in concrete walls? Deep vertical cracks in concrete walls, especially those that affect the structure, require crack injection systems. These systems involve injecting a high-strength resin, such as epoxy or polyurethane, into the crack to fill the void and restore the structural integrity of the wall. This method is particularly effective for basement walls and other load-bearing structures.

- Can overhead concrete repair products be used on exterior surfaces exposed to the elements? Yes, many overhead concrete repair products are designed to be weather-resistant and can be used on exterior surfaces. It’s important to choose products that offer resistance to freeze-thaw cycles, UV rays, and moisture to ensure long-lasting durability in outdoor environments.

- How do I know if the damage to my vertical concrete surface requires structural repair? If the damage involves deep cracks, spalling, or significant displacement of the concrete, it may require structural repair. Additionally, if the surface in question is load-bearing, even minor damage can indicate underlying structural issues that need to be addressed with specialist repair products.

- What are the most common causes of vertical cracks in basement walls? Vertical cracks in basement walls are often caused by the natural settling of the building, hydrostatic pressure from groundwater, or shrinkage of the concrete as it cures. These cracks can allow water infiltration, leading to moisture problems and weakening the foundation.

- What is the difference between patching and repairing a vertical surface? Patching a surface involves filling small cracks, chips, or voids to restore the appearance and prevent further damage. Repairing, on the other hand, involves addressing more significant structural issues, such as deep cracks or spalling, and may require the use of more specialised products to ensure long-term durability.

- Do I need to remove all damaged material before applying a repair product? Yes, it’s important to remove any loose, damaged, or deteriorating material before applying a repair product. This ensures that the new material will bond properly to the substrate, resulting in a stronger and more durable repair.

- How long does it take for vertical and overhead concrete repair products to cure? The curing time for vertical and overhead concrete repair products varies depending on the specific product and environmental conditions. Some products cure within a few hours, while others may take several days to reach full strength. Always follow the manufacturer’s instructions for curing times.

- Can I apply a protective coating immediately after repairing a vertical surface? No, it’s important to allow the repair to fully cure before applying any protective coatings or sealers. Applying a coating too soon can interfere with the curing process and reduce the effectiveness of both the repair and the coating.

- What are the risks of not addressing damage to vertical or overhead surfaces promptly? Failing to repair damage to vertical or overhead surfaces can lead to further deterioration, including increased cracking, spalling, or even structural failure. Additionally, untreated damage can allow water infiltration, leading to moisture issues such as mould, mildew, and corrosion of embedded reinforcement.

- What should I consider when choosing between different vertical concrete repair products? When selecting a repair product for vertical concrete surfaces, consider factors such as the type of damage, the location (interior vs. exterior), the load-bearing requirements, and the environmental conditions. Additionally, look for products that offer quick-setting properties to ensure that the material stays in place during application.